Styrene-butadiene emulsion for carpets and preparation method thereof

A styrene-butadiene emulsion and carpet technology, applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor softness, undurable carpets, poor strength, etc. Effect of cluster pull-out force and intermolecular force improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

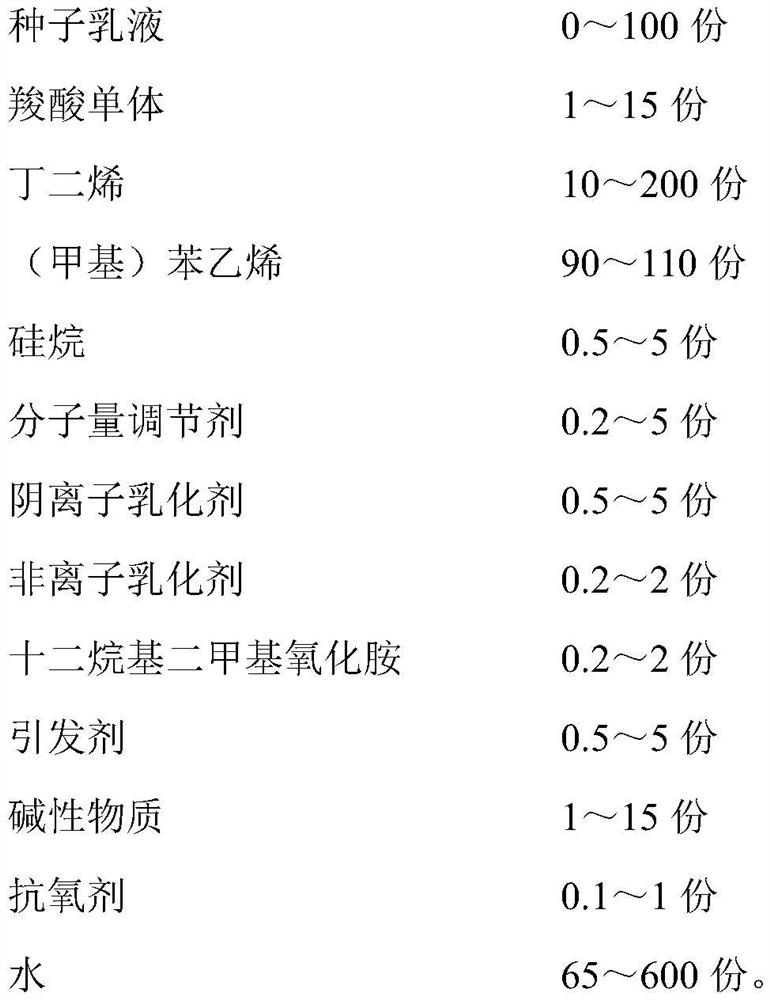

[0024] A kind of styrene-butadiene emulsion for carpet, comprises the component of following parts by weight:

[0025]

[0026] The preparation method of above-mentioned carpet styrene-butadiene emulsion, comprises the following steps:

[0027] The 2000ml pressurized reaction kettle is first evacuated, the vacuum degree is -0.095MPa, add 0.1g of sodium lauryl sulfate, 0.1g of potassium persulfate, and 59.2g of distilled water to completely dissolve into an aqueous solution, then add 2g of styrene, start stirring, and heat up to 60°C. At the same time, 1 gram of acrylic acid, 10 grams of butadiene, 88 grams of styrene, 0.2 grams of n-dodecanethiol and 0.5 grams of γ-(2,3-epoxypropoxy)propyltrimethoxysilane were added dropwise at 60°C. and 0.4 grams of sodium lauryl sulfate, 0.2 grams of polyoxyethylene (20) sorbitan monooleate, 0.4 grams of potassium persulfate, 0.2 grams of lauryl dimethylamine oxide and 10 g distilled water mixed water solution. The dropwise addition ti...

Embodiment 2

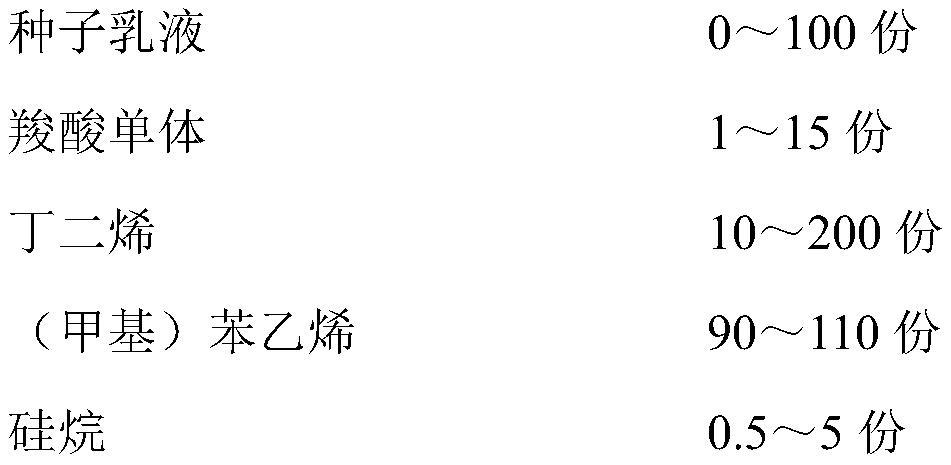

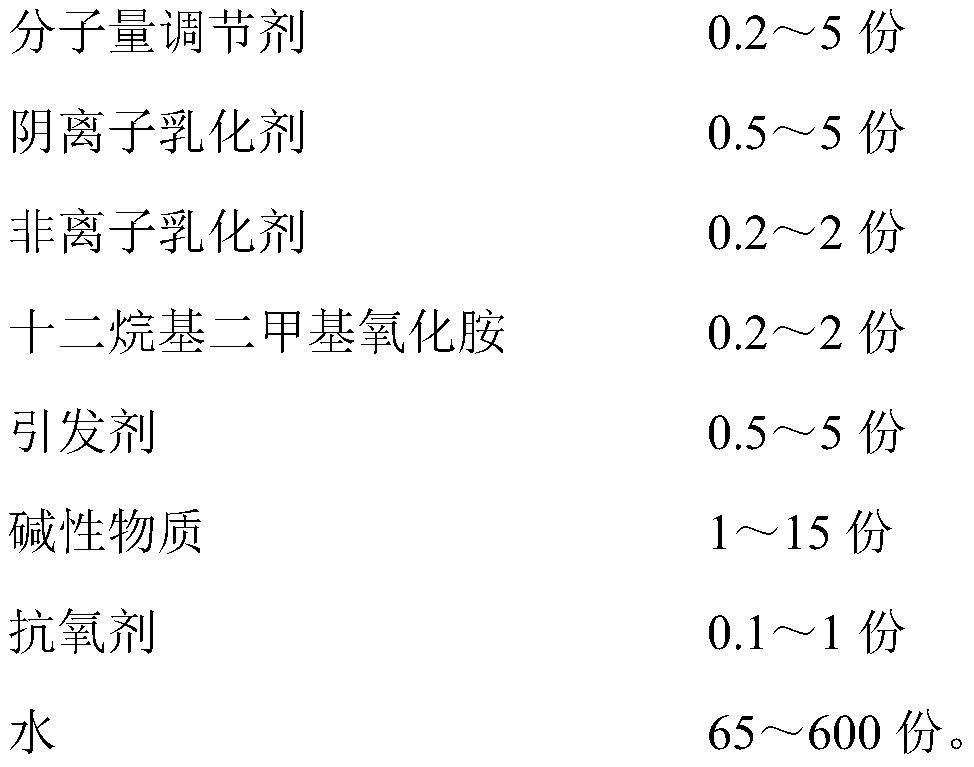

[0029] A kind of styrene-butadiene emulsion for carpet, comprises the component of following parts by weight:

[0030]

[0031]

[0032] The preparation method of above-mentioned carpet styrene-butadiene emulsion, comprises the following steps:

[0033] The 2000ml pressurized reaction kettle is first evacuated, vacuum degree-0.095MPa, adds 100 grams of 40wt% seed emulsion (particle diameter 40nm), 2 grams of sodium dodecyl naphthalene sulfonate, 1 gram of sorbitan monooleate, 1 gram of sodium persulfate and 447.5 grams of distilled water were completely dissolved into an aqueous solution, stirring was started, and the temperature was raised to 90°C. At the same time, 15 grams of methacrylic acid, 200 grams of butadiene, 110 grams of methylstyrene, 5 grams of tert-dodecylmercaptan and 5 grams of γ-methacryloxypropyl trimethoxysilane were added dropwise at 90 ° C. and 3 grams of sodium dodecyl naphthalene sulfonate, 1 gram of sorbitan monolaurate, 2 grams of lauryldimethy...

Embodiment 3

[0035] A kind of styrene-butadiene emulsion for carpet, comprises the component of following parts by weight:

[0036]

[0037]

[0038] The preparation method of above-mentioned carpet styrene-butadiene emulsion, comprises the following steps:

[0039] The 2000ml pressurized reaction kettle is first vacuumed, and the vacuum degree is -0.095MPa, and 30 grams of 20wt% seed emulsion (30nm in particle size) are added, 0.5 grams of dicyclohexyl-2-sodium sulfosuccinate, 0.5 grams of ammonium persulfate, 138.5 grams Distilled water, completely dissolved into an aqueous solution, started stirring, and raised the temperature to 80°C. Simultaneously, a mixed monomer of 10 grams of methacrylic acid, 100 grams of butadiene, 98 grams of styrene, 3 grams of n-dodecylmercaptan and 3 grams of γ-aminopropyltriethoxysilane was added dropwise at 80°C; and A mixed aqueous solution of 2 grams of sodium dialkyl-2-sulfosuccinate, 1.5 grams of polyoxypropylene stearate, 1 gram of lauryl dimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com