High-molecular-weight macromonomer polyether, polycarboxylate superplasticizer and preparation method thereof

A high molecular weight, macromonomer technology, applied in the fields of organic chemistry and building materials, can solve the problems of low molecular weight, poor viscosity reduction effect, and long reaction time of polycarboxylate superplasticizer monomer polyether. Increase product profitability, reduce residual and side reactions, and improve the effect of reaction conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

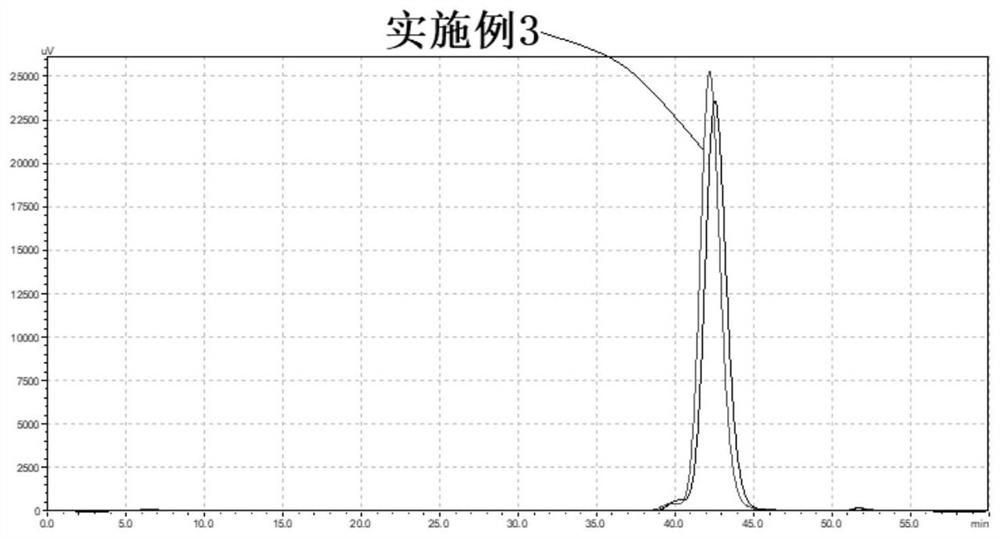

Image

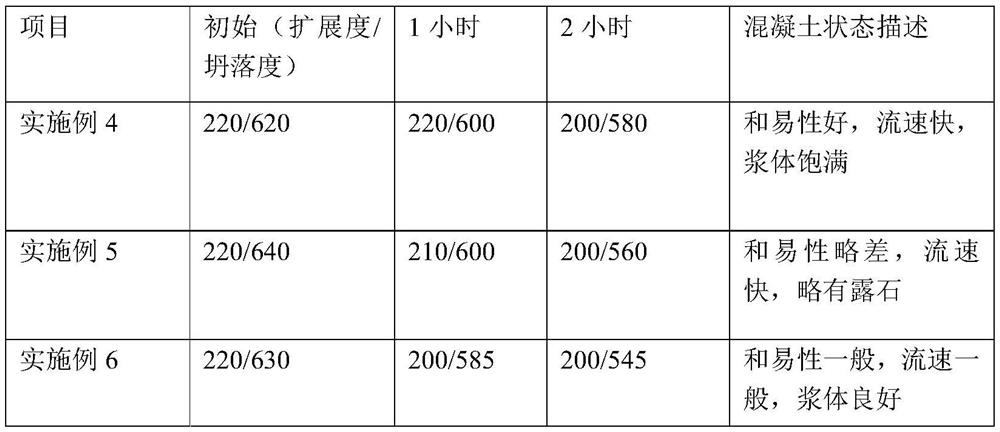

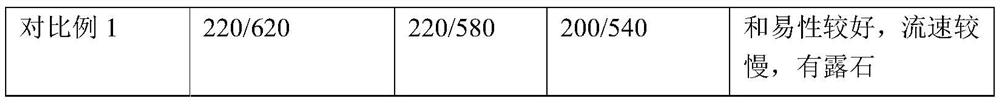

Examples

preparation example Construction

[0042]In a specific embodiment, the present application provides a method for preparing a polycarboxylic acid water reduction agent depleted monomer polyether comprising the steps of: in a reactor with nitrogen and can be a nitrogen bubble device. , The hydroxy ester initiation agent is stirred well, and moisture is detected; then the ethylene oxide, the propanoxide or mixture thereof is added to the appropriate catalyst, so that the weight average molecular weight is 2,400 or more, resulting in high The molecular weight is large. When the moisture is detected, the moisture is less than 0.05% is qualified. If moisture is unqualified, it will cause high impurity content in the product. The impurities are mainly PEG, which will affect the synthesis of the water reducer, which will produce a large amount of foam in the synthesis, and severely affect the water reducer. Demand and other indicators.

[0043] There is currently no related products to be applied to the water repellent mot...

Embodiment 1

[0071] Raw material formulation: 500 hydroxyethyl acrylate, 2.1 potassium hydroxide.

[0072] Preparation method: 500 parts of acrylate hydroxyethyl ester to add a reactor with a ventilator, and the apparatus further comprises emptying and vacuum systems. The stirring was evenly stirred, and the moisture was passed, then stirred, and the mixture was added to the preparation of the potassium hydroxide to prepare the polycarboxylic acid water reduction agent monomer polyether intermediate 1. The prepared polycarboxylic acid-based water reducer monomer polyether intermediate 1 is metered into the high pressure reactor (or the reaction kettle of the ethoxy apparatus) to remove gas blocker components such as oxygen to obtain a high molecular weight. Large monomer polyether intermediate 2.

[0073] 650 part of the propylene oxide is passed, and the reaction temperature is measured by the reaction temperature, preferably from 100 to 145 ° C, no more than 155 ° C. At the same time, the co...

Embodiment 2

[0076] Raw material formula: 500 hydroxylar acid hydroxylate, 2.1 potassium hydroxide.

[0077] Preparation method: 500 servohydroxylar esters were added to the reactor with a venting device, and the apparatus also included emptying and vacuum systems. The stirring was evenly stirred, and the moisture was passed, then stirred, and the mixture was added to the preparation of potassium hydroxide to prepare the polycarboxylic acid-water water reduction agent monomer polyether intermediate. The prepared polycarboxylic acid-based water reducer monomer polyether intermediate 1 is metered into the high pressure reactor (or the reaction kettle of the ethoxy apparatus) to remove gas blocker components such as oxygen to obtain a high molecular weight. Large monomer polyether intermediate 2.

[0078] 650 part of the propylene oxide is passed, and the reaction temperature is measured by the reaction temperature, preferably from 100 to 145 ° C, no more than 155 ° C. At the same time, the contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com