Automatic real stone paint production method

A production method and technology of real stone paint, applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve problems such as easy falling off, and achieve the effects of good cleaning performance, easy modeling and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

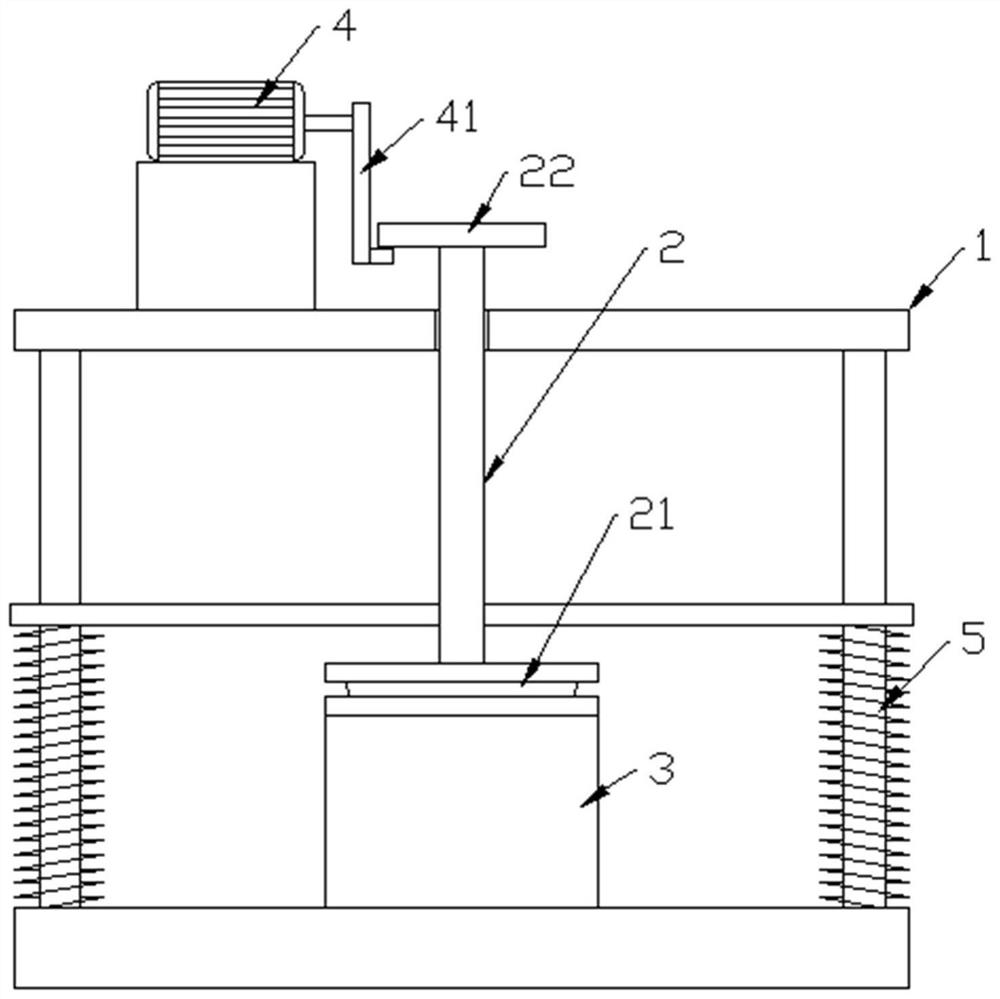

[0028] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0029] A kind of automatic real stone paint production method, comprises the following steps:

[0030] Step 1, put the raw materials into the automatic genuine stone paint production equipment, the raw materials include pure water mixed with several auxiliary agents; wherein, in terms of parts by mass, the raw material formula is composed of:

[0031] 80-150 parts of pure water;

[0032] 4-6 parts of cellulose;

[0033] Wetting agent 50-60 parts;

[0034] 10-20 parts of antifreeze;

[0035] 10-20 parts of film-forming aids;

[0036] 1-2 parts of PH regulator;

[0037] 2-4 parts of defoamer;

[0038] Step 2, adding thickener and emulsion, in parts by mass, thickener and emulsion are composed of:

[0039] 2-6 parts of thickener;

[0040] Emulsion 200-300;

[0041] Step 3: Thickener is put in while viscosity testing is carried out until the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com