Metal part surface coating strengthening method based on laser beam heat treatment

A technology of metal parts and surface coating, which is applied in the field of surface coating strengthening of metal parts based on laser beam heat treatment, which can solve the problems of poor strengthening effect and uneven distribution of metal surface strengthening degree, so as to improve smoothness and heat treatment efficiency , Improve the effect of hardening degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for strengthening the surface coating of metal parts based on laser beam heat treatment includes the following steps.

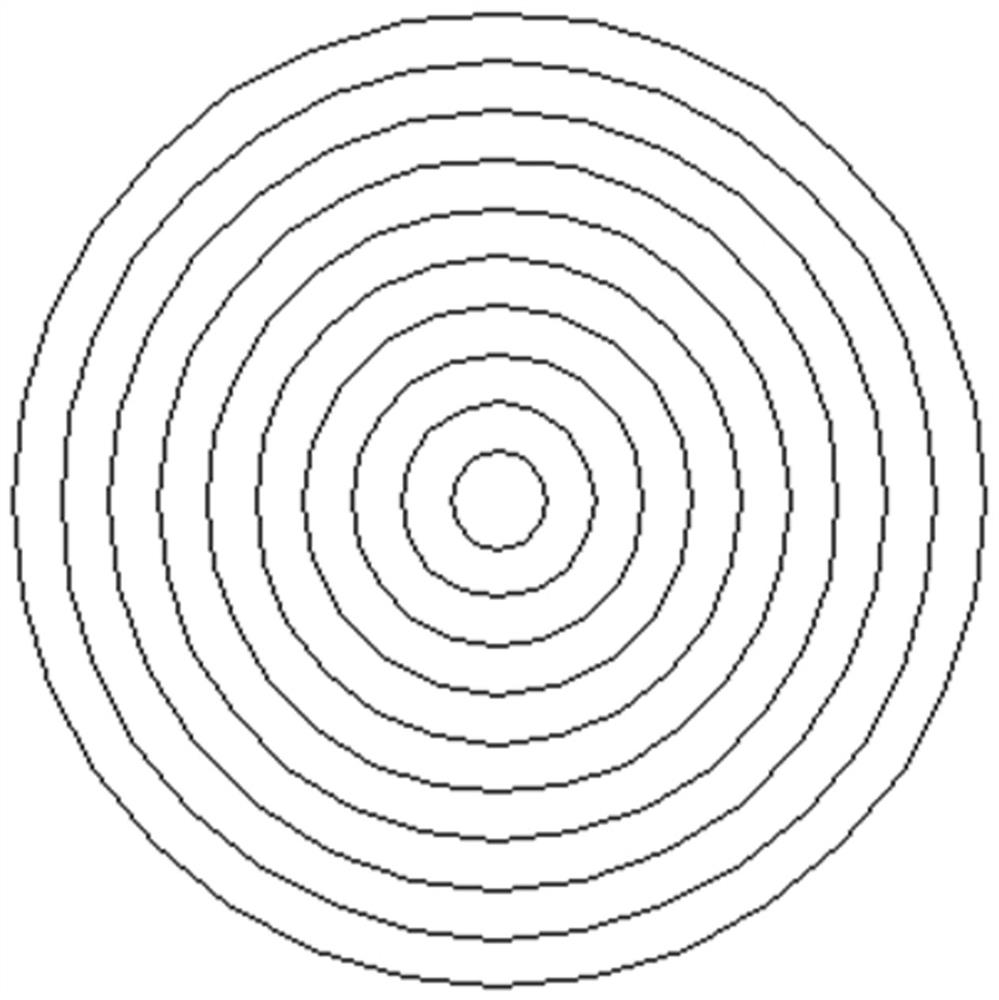

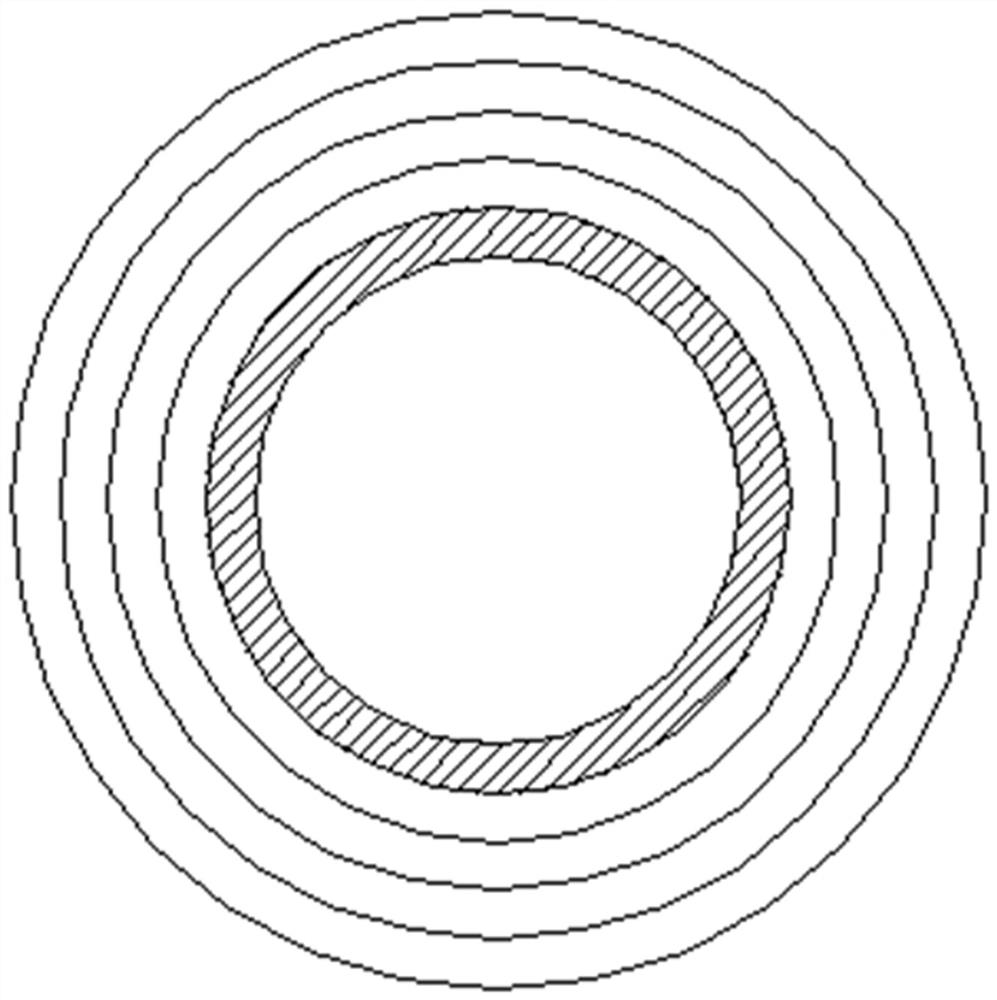

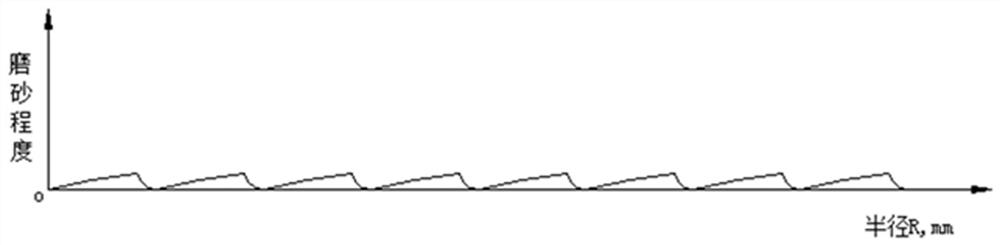

[0034] Step 1, such as figure 1 and image 3 As shown, the surface of the metal component is sanded to form a plurality of concentrically distributed frosted ring zones, and there is no gap between adjacent frosted ring zones. The frosting degree of the same frosted ring zone gradually increases along the direction away from the center of the circle, and the frosting degree of the middle and low degree zone of the inner frosted ring zone is smaller than that of the middle and high degree zone of the outer frosted ring zone. The change of the frosting degree from the high degree area to the low degree area in the frosted ring zone is in the shape of a quarter wavelength of the slowing growth trend in the sine wave, in which the adjacent frosted ring zone is provided with a buffer zone connecting the high degree zone and the low degree zone ...

Embodiment 2

[0039] The method for strengthening the surface coating of metal parts based on laser beam heat treatment specifically includes the following steps.

[0040] Step 1, such as figure 1 and image 3As shown, the surface of the metal component is sanded to form a plurality of concentrically distributed frosted ring zones, and there is no gap between adjacent frosted ring zones. The frosting degree of the same frosted ring zone gradually increases along the direction away from the center of the circle, and the frosting degree of the middle and low degree zone of the inner frosted ring zone is smaller than that of the middle and high degree zone of the outer frosted ring zone. The change of the frosting degree from the high degree area to the low degree area in the frosted ring zone is in the shape of a quarter wavelength of the slowing growth trend in the sine wave, in which the adjacent frosted ring zone is provided with a buffer zone connecting the high degree zone and the low d...

Embodiment 3

[0045] The method for strengthening the surface coating of metal parts based on laser beam heat treatment specifically includes the following steps.

[0046] Step 1, such as figure 1 and image 3 As shown, the surface of the metal component is sanded to form a plurality of concentrically distributed frosted ring zones, and there is no gap between adjacent frosted ring zones. The frosting degree of the same frosted ring zone gradually increases along the direction away from the center of the circle, and the frosting degree of the middle and low degree zone of the inner frosted ring zone is smaller than that of the middle and high degree zone of the outer frosted ring zone. The change of the frosting degree from the high degree area to the low degree area in the frosted ring zone is in the shape of a quarter wavelength of the slowing growth trend in the sine wave, in which the adjacent frosted ring zone is provided with a buffer zone connecting the high degree zone and the low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com