Flexible capacitive pressure sensor and preparation method thereof

A pressure sensor and flexible capacitor technology, applied in the field of flexible sensors, can solve the problems of low relative value and reduce the flexibility requirement of the electrode layer, and achieve the effect of improving sensitivity, improving accuracy and long-term effect, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

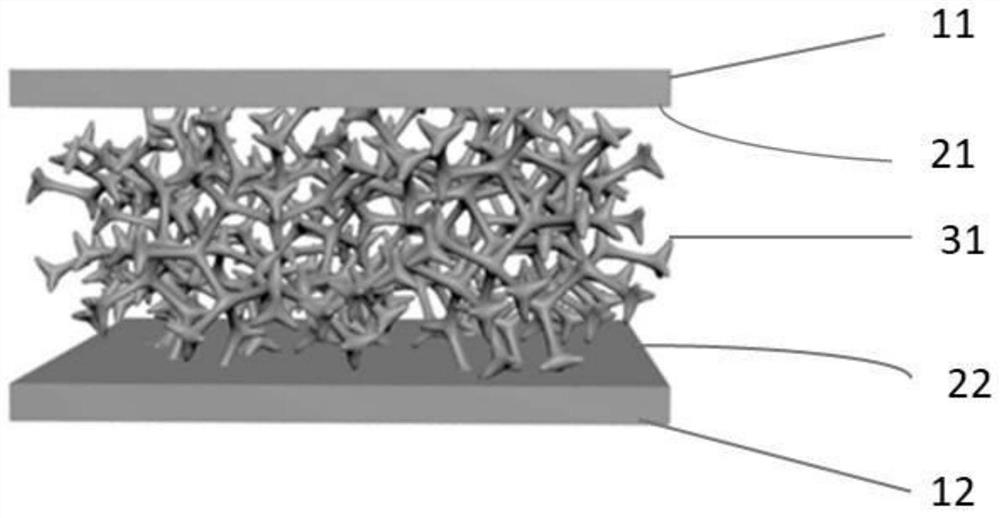

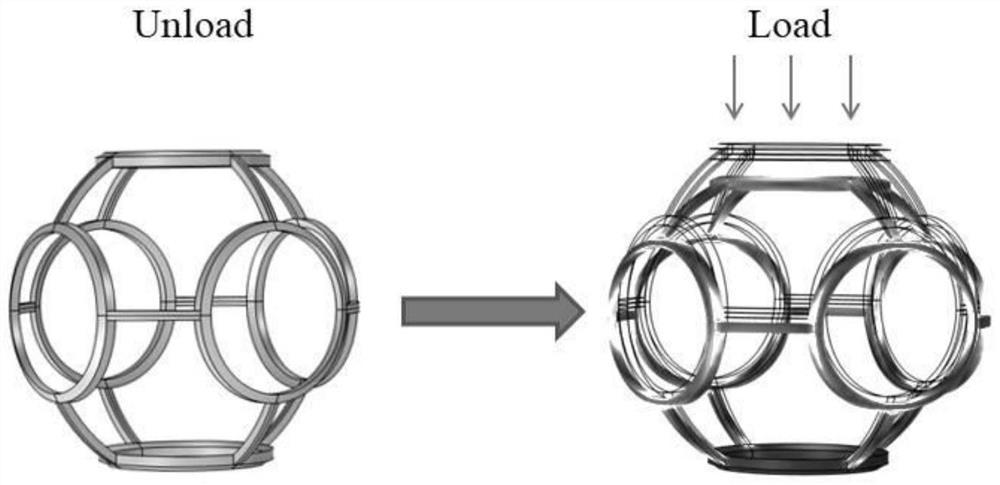

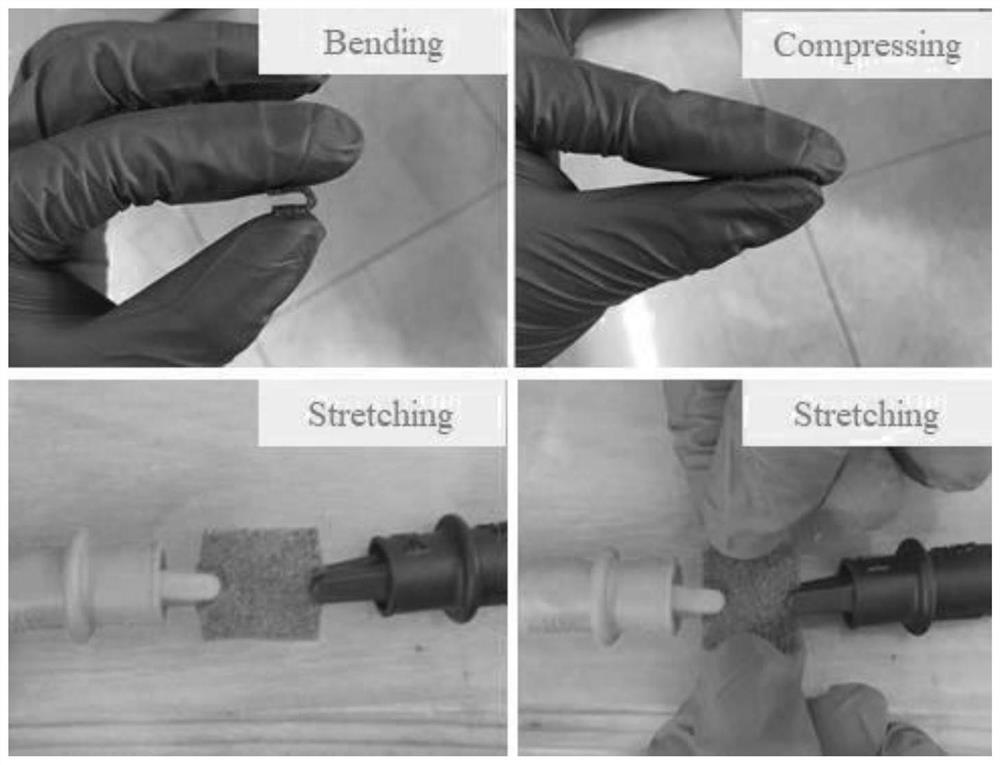

[0038] This embodiment provides a flexible capacitive pressure sensor, such as figure 1 As shown, it includes: a first electrode plate 11, a second electrode plate 12, a flexible dielectric layer 31 and an electrostatic film, the first electrode plate 11 is opposite to the second electrode plate 12, and the first electrode plate 11 and the second electrode plate The conductive film surface of electrode plate 12 is all attached with electrostatic film, and promptly the conductive film surface of first electrode plate 11 is all attached with first electrostatic film 21, and the conductive film surface of second electrode plate 12 is all attached with second electrostatic film 22, The flexible dielectric layer 31 is disposed between the first electrode plate 11 and the second electrode plate 12 . Wherein, the flexible dielectric layer 31 is a composite material obtained by combining modified titanium dioxide and polyurethane sponge. The compression of the flexible dielectric lay...

Embodiment 2

[0045] This embodiment provides a flexible capacitive pressure sensor whose structure is consistent with that of Embodiment 1, and its preparation method includes:

[0046] (1) First cut the polyurethane sponge into a size (2×2×0.1 cm), wash it with ultrapure water, and dry it at 50° C. for 10 h.

[0047] (2) Then, take 10 ml of 1 mg / ml titanium dioxide aqueous solution and put it in a beaker, and stir it well at 30°C. Then 0.1 g of APTES was added, and ultrasound was performed for 1 h at room temperature to form a second solution.

[0048] (3) Immerse the polyurethane sponge in the second solution for 3 minutes and take it out, that is, the mass ratio of titanium dioxide nanoparticles to polyurethane sponge is 2:3, and APTES is used as an intermediate to connect polyurethane and titanium dioxide, so that the two are closely combined without destroying its structure. The corresponding dielectric layer M2 is obtained.

[0049] (4) Wash the flexible electrode ITO / PET with ultr...

Embodiment 3

[0051] This embodiment provides a flexible capacitive pressure sensor whose structure is consistent with that of Embodiment 1, and its preparation method includes:

[0052] (1) First cut the polyurethane sponge into a size (2×2×0.1 cm), wash it with ultrapure water, and dry it at 50° C. for 10 h.

[0053] (2) Then take 15ml of 1mg / ml titanium dioxide aqueous solution and put it in a beaker, and heat it in a water bath at 90°C to evaporate the solvent to 10ml. Then 0.1 g of APTES was added, and ultrasound was performed for 1 h at room temperature to form a third solution.

[0054] (3) Immerse the polyurethane sponge in the third solution for 3 minutes and take it out, that is, the mass ratio of titanium dioxide nanoparticles to polyurethane sponge is 1:1, and APTES is used as an intermediate to connect polyurethane and titanium dioxide, so that the two are closely combined without destroying its structure. The corresponding dielectric layer 3 is obtained.

[0055] (4) Wash th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com