Method for preparing MnO2@porous carbon composite wave absorbing material

A technology of composite microwave-absorbing materials and porous carbon, which is applied in the field of composite microwave-absorbing materials, can solve the problems of high cost, single microwave absorption response frequency band, and high equipment requirements, and achieve high cost, simple follow-up processing, and high equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a concrete implementation step of the present invention is as follows:

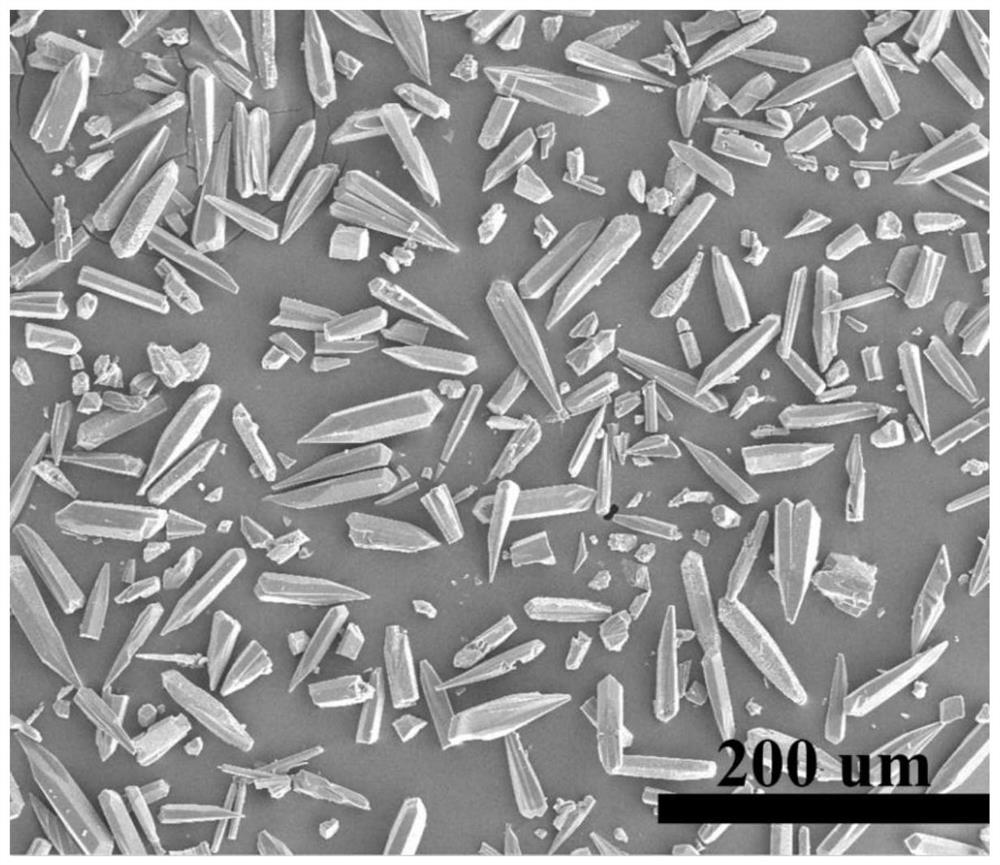

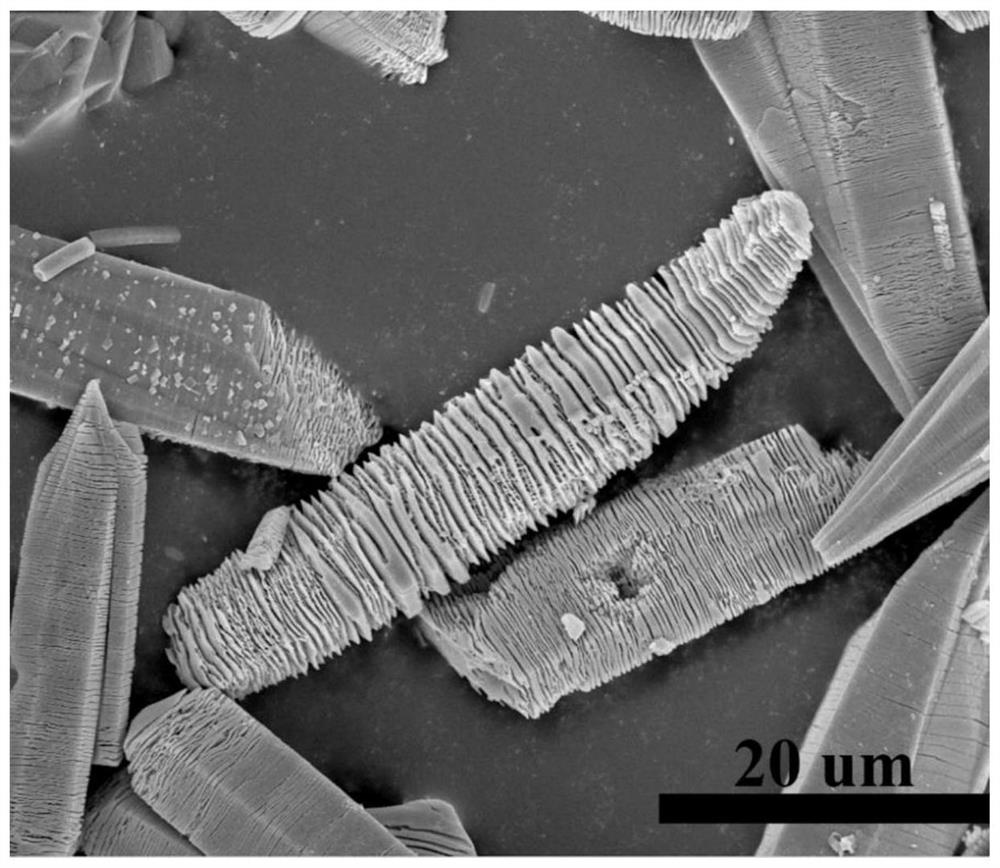

[0029] Step 1, the manganese chloride tetrahydrate of 3.3mmol, the 2,5-dihydroxyterephthalic acid of 1.0mmol are dissolved in the mixed solution of the DMF of 45mL, the deionized water of 3mL and the ethanol of 3mL together, then transfer to In an autoclave, heat preservation at 135°C for 24h, and the obtained product was centrifuged and washed three times with DMF; finally placed in a vacuum oven and dried under vacuum at 60°C to obtain Mn-MOF-74 rod-shaped crystals;

[0030] Step 2. The Mn-MOF-74 rod-shaped crystals prepared in step 1 were heated from room temperature to 700°C under the conditions of a nitrogen atmosphere and a heating rate of 2°C / min and calcined for 2h, and naturally cooled to room temperature under a nitrogen atmosphere to obtain MnO @NPC.

[0031] Step 3. Dissolve 0.1g of MnO@NPC prepared in step 2, 0.158g of potassium permanganate, and 5mL of 1.0M hydrochloric...

Embodiment 2

[0032] Example 2: The difference between this example and the specific example 1 is that in step 2, the Mn-MOF-74 rod-shaped crystals prepared in step 1 were heated from room temperature to 800 °C under a nitrogen atmosphere and a heating rate of 2 °C / min. ℃ and roasted for 2h, and naturally cooled to room temperature under a nitrogen atmosphere. Others are the same as in Example 1.

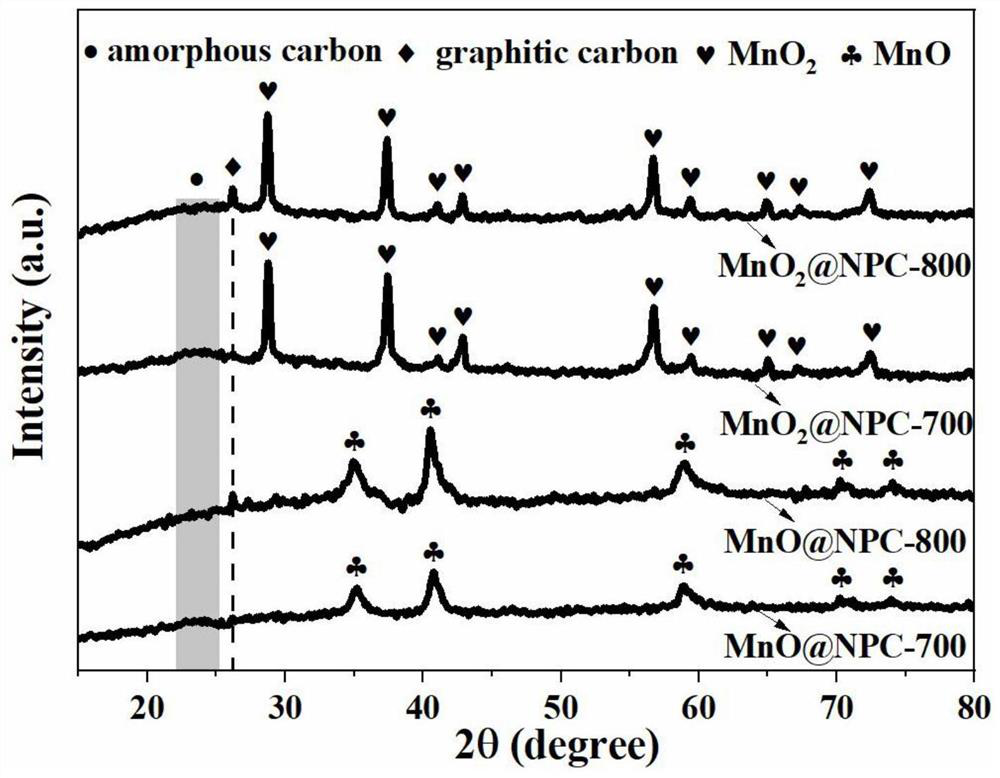

[0033] figure 1 For the X-ray diffraction pattern, the pyrolysis products of Mn-MOF-74 at 700 °C and 800 °C are labeled as MnO@NPC-700 and MnO@NPC-800, respectively. The oxidation products of MnO@NPC-700 and MnO@NPC-800 are labeled as MnO, respectively 2 @NPC-700 and MnO 2 @NPC-800. From figure 1It can be seen that MnO@NPC-700 and MnO@NPC-800 exhibit five distinct peaks at 34.9°, 40.5°, 58.7°, 70.2° and 73.8°, corresponding to the (111), (200), (220), (311) and (222) crystal planes. MnO 2 @NPC-700 and MnO 2 The XRD pattern of @NPC-800 is also similar, showing nine distinct peaks at 28.7°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com