High-performance organic mine reinforcing material

A technology for reinforcing materials and organic minerals, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve problems such as potential safety hazards and general strength, and achieve the effects of strong applicability, fast on-site construction, and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

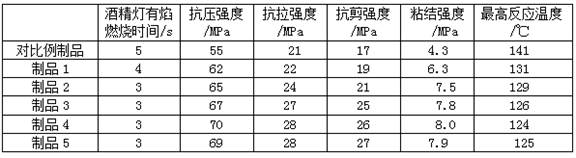

Examples

Embodiment 1

[0023] A high-performance organic mineral reinforcement material, containing two components A and B, component A is composed of 200 parts by weight of isocyanate, 20 parts of polyether polyol MV500, 20 parts of polyether polyol GY420, 10 parts of poly Ether polyol DL-204, 10 parts of graphene oxide grafted polyaniline, 5 parts of polycarboxylate superplasticizer, 3 parts of N,N bis(2-hydroxyethyl)aminomethylphosphonic acid diethyl ester and 3 parts of N-dimethylcyclohexylamine.

[0024] Component B includes 80 parts of polyisocyanate, 20 parts of short basalt fiber, and 5 parts of vinyl acetate; the length of the short basalt fiber is 0.5-2mm.

[0025] Component A and component B are injected into the cracks of loose and broken coal and rock mass through a special pneumatic grouting pump and mixing gun according to the volume ratio of 1:1.1, and are quickly cemented with the coal and rock mass to form a continuous, complete, high-quality The strength of the consolidated body,...

Embodiment 2

[0027] A high-performance organic mineral reinforcement material, containing A and B two components, A component is composed of 300 parts by weight of isocyanate, 20 parts of polyether polyol MV500, 20 parts of polyether polyol GY420, 10 parts of poly Ether polyol DL-204, 20 parts of graphene oxide grafted polyaniline, 8 parts of polycarboxylate superplasticizer, 5 parts of N,N bis(2-hydroxyethyl)aminomethylphosphonic acid diethyl ester and 3 parts halophosphate FR-780.

[0028] Component B includes 100 parts of polyisocyanate, 15 parts of short basalt fiber, and 5 parts of ethylene; the length of short basalt fiber is 0.5-2mm.

[0029] Component A and component B are injected into the cracks of loose and broken coal and rock mass through a special pneumatic grouting pump and mixing gun according to the volume ratio of 1:0.9, and are quickly cemented with the coal and rock mass to form a continuous, complete, high-quality The strength of the consolidated body, thus playing a ...

Embodiment 3

[0031] A high-performance organic mineral reinforcement material, containing two components A and B, component A is composed of 350 parts by weight of isocyanate, 10 parts of polyether polyol GY420, 15 parts of polyether polyol DL-204, 15 parts Polyether polyol JH303, 10 parts of graphene oxide grafted polyaniline, 8 parts of polycarboxylate superplasticizer, 5 parts of N,N bis(2-hydroxyethyl)aminomethylphosphonic acid diethyl ester and 3 parts halophosphate FR-780.

[0032] Component B includes 50 parts of polyisocyanate, 20 parts of short basalt fiber, and 10 parts of vinyl laurate; the length of the short basalt fiber is 0.5-2mm.

[0033] Component A and component B are injected into the cracks of loose and broken coal and rock mass through a special pneumatic grouting pump and mixing gun at a volume ratio of 1:1, and are quickly cemented with the coal and rock mass to form a continuous, complete, high-strength Consolidation body, so as to play a reinforcing role.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com