Photocatalytic fresh-keeping coating and super-fresh paper coated with same

A photocatalysis and coating technology, applied in paper coatings, polyether coatings, antifouling/underwater coatings, etc., can solve the problem of no preservation function, and achieve the effect of solving the decline of catalytic effect, prolonging the preservation period and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

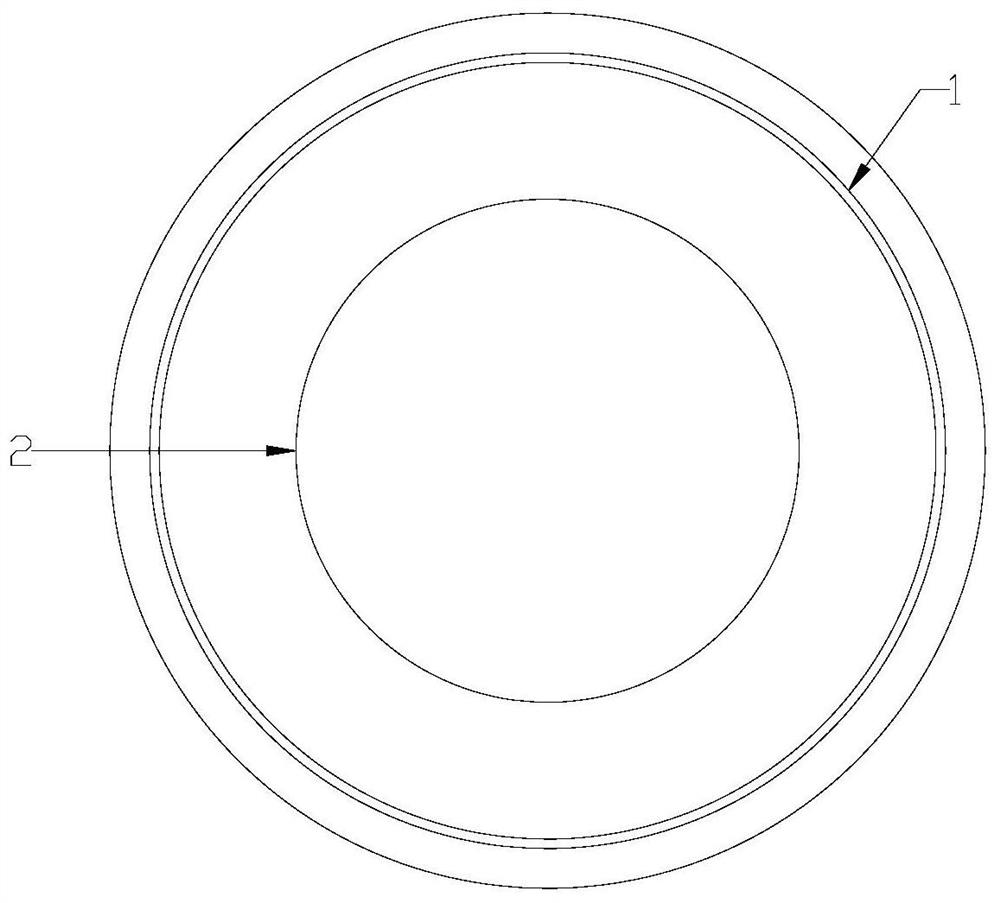

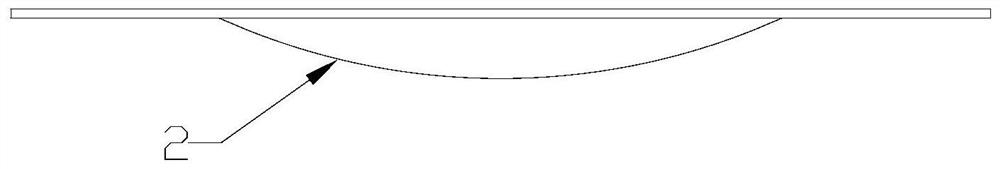

[0027] Weigh 0.02 parts by weight of photocatalytic nano-titanium dioxide particles with a coating layer on the surface, 0.002 parts of slow-release ethylene inhibitors, 0.002 parts of binders and 0.02 parts of soluble polymers, stir and mix, and mix A photocatalytic fresh-keeping coating is prepared. Then the photocatalyzed fresh-keeping paint is sprayed on at least one surface of the paper body layer.

[0028] Wherein, the coating layer is silicon dioxide. Preparation method: first mix 100 parts by weight of nano-titanium dioxide and 300 parts of water, and then fully stir for 10 minutes, then add 1 part of long-chain alkyl surfactant and mix, emulsify for 30 minutes under stirring, then add ethyl silicate, fully Stir for 2 hours, and finally calcinate the mixed solution at 500° C. for 2 hours to obtain nanometer titanium dioxide particles coated with silicon dioxide.

[0029] The slow-release ethylene inhibitor is a microcapsule ethylene inhibitor. The preparation method...

Embodiment 2

[0036] 5 parts by weight of photocatalytic nano-titanium dioxide particles with a coating layer on the surface, 0.1 part of slow-release ethylene inhibitor, 5 parts of binder and 0.05 part of soluble polymer were weighed.

[0037] The cladding layer is montmorillonite. Preparation method: First, add 0.8ml of titanium tetrachloride to 40ml of hydrochloric acid solution with a concentration of 1mol / L and stir for 40min to obtain a light yellow transparent acidic sol of titanium dioxide, then add 1% sodium base to 25ml of acidic sol of titanium dioxide Montmorillonite solution (1g of montmorillonite was added to 50mL of deionized water and 50mL of absolute ethanol mixture and stirred for 10min) and stirred at 60°C for 4h, then centrifugally filtered, fully washed with deionized water for 3 times until no Cl - (using 1% AgNO, solution detection), and then roasting at 500° C. for 2 h to obtain nanometer titanium dioxide particles coated with montmorillonite.

[0038] Others are t...

Embodiment 3

[0040] 9.5 parts by weight of photocatalytic nano-titanium dioxide particles with a coating layer on the surface, 0.18 parts of slow-release ethylene inhibitor, 9.5 parts of binder and 0.09 parts of soluble polymer were weighed.

[0041] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com