Anti-seismic fire-resistant steel plate with thickness being 100 mm and yield strength being 460 MPa grade and manufacturing method thereof

A yield strength and refractory technology, applied in the field of alloy steel manufacturing, can solve problems such as expensive costs, and achieve the effects of improving hardenability, reducing costs, and reducing temper brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

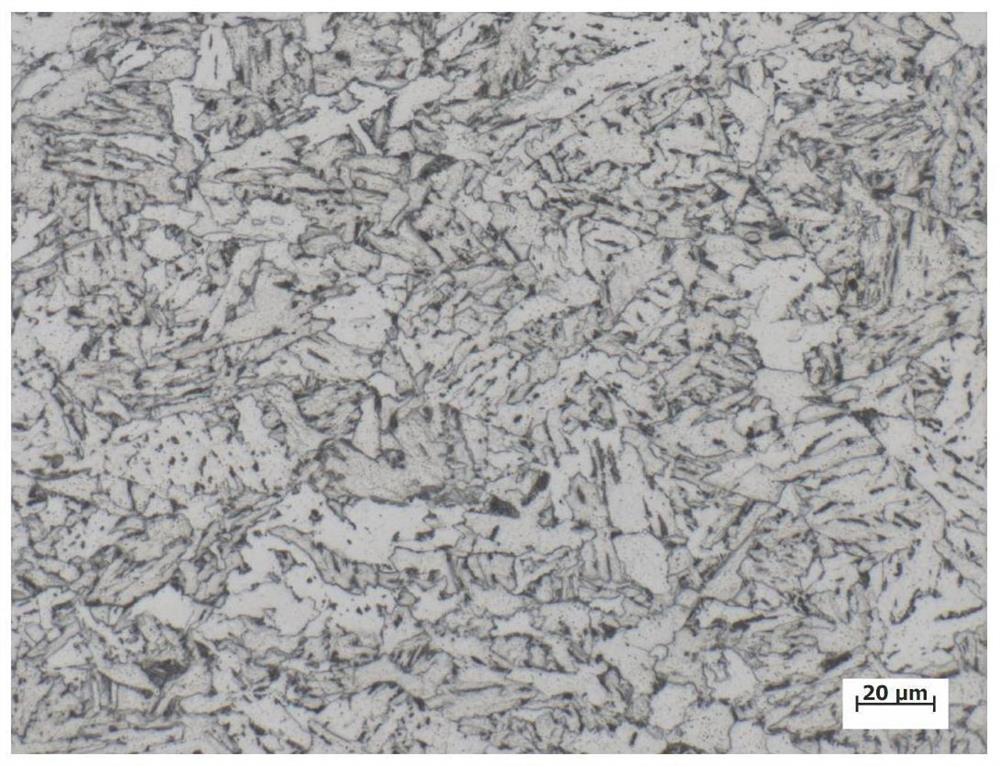

Embodiment 1

[0028] A 100mm-thick anti-seismic fire-resistant steel plate with a yield strength of 460MPa, the mass percentage of each element in its chemical composition is: C: 0.065%, Si: 0.15%, Mn: 1.58%, P: 0.014%, S: 0.008%, Cr: 0.46% , Mo: 0.17%, Nb: 0.086%, V: 0.02%, Ti: 0.015%, Al: 0.028%, N: 0.005%. The balance is Fe and unavoidable impurity elements. Its manufacturing method comprises the following process steps:

[0029](1) Through the converter smelting process, the refining process outside the furnace, and the molten steel pouring continuous casting billet process, pouring into a billet with a thickness of 320mm and a length of 3000mm, the chemical composition of the billet is: C: 0.065%, Si: 0.15%, Mn : 1.58%, P: 0.014%, S: 0.008%, Cr: 0.46%, Mo: 0.17%, Nb: 0.086%, V: 0.02%, Ti: 0.015%, Al: 0.028%, N: 0.005%, the rest For Fe and inevitable impurity elements.

[0030] (2) Heating process of the slab heating furnace: the heating temperature is 1140°C, and the furnace time is...

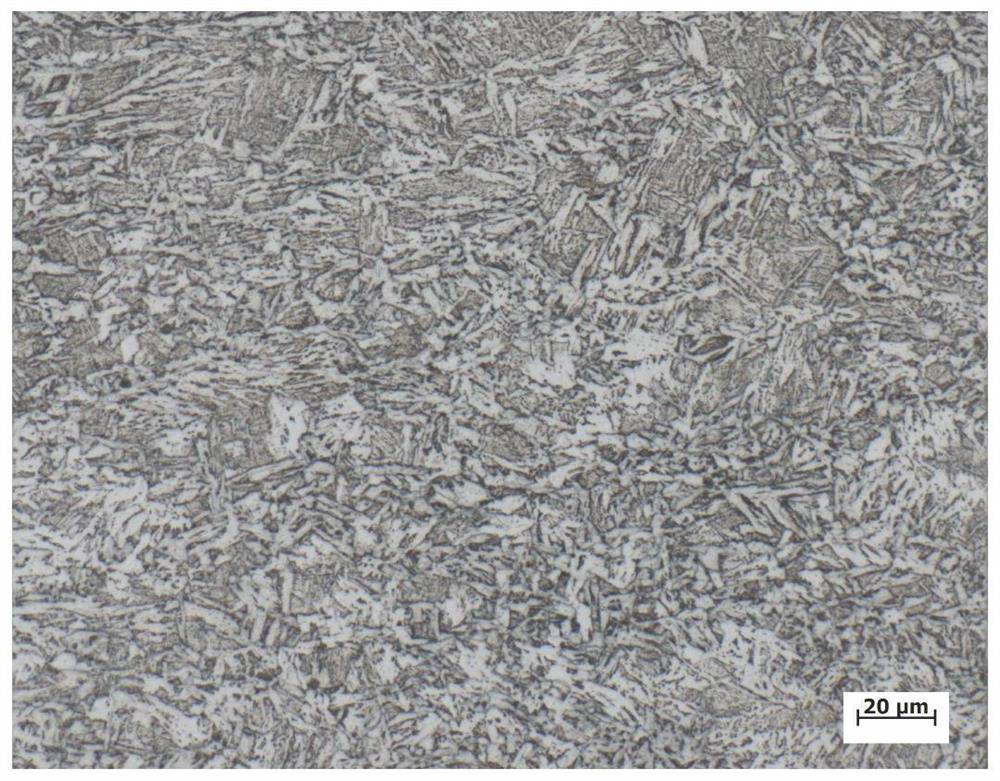

Embodiment 2

[0034] A 100mm-thick anti-seismic fire-resistant steel plate with a yield strength of 460MPa, the mass percentage of each element in its chemical composition is: C: 0.089%, Si: 0.25%, Mn: 1.21%, P: 0.012%, S: 0.009%, Cr: 0.34% , Mo: 0.15%, Nb: 0.068%, V: 0.03%, Ti: 0.022%, Al: 0.035%, N: 0.004%. The balance is Fe and unavoidable impurity elements. Its manufacturing method comprises the following process steps:

[0035] (1) Through the converter smelting process, the refining process outside the furnace, and the molten steel pouring continuous casting billet process, pouring into a billet with a thickness of 320mm and a length of 3000mm, the chemical composition of the billet is: C: 0.089%, Si: 0.25%, Mn : 1.21%, P: 0.012%, S: 0.009%, Cr: 0.34%, Mo: 0.15%, Nb: 0.068%, V: 0.03%, Ti: 0.022%, Al: 0.035%, N: 0.004%, the rest For Fe and inevitable impurity elements.

[0036] (2) Heating process of the slab heating furnace: the heating temperature is 1160°C, and the furnace time i...

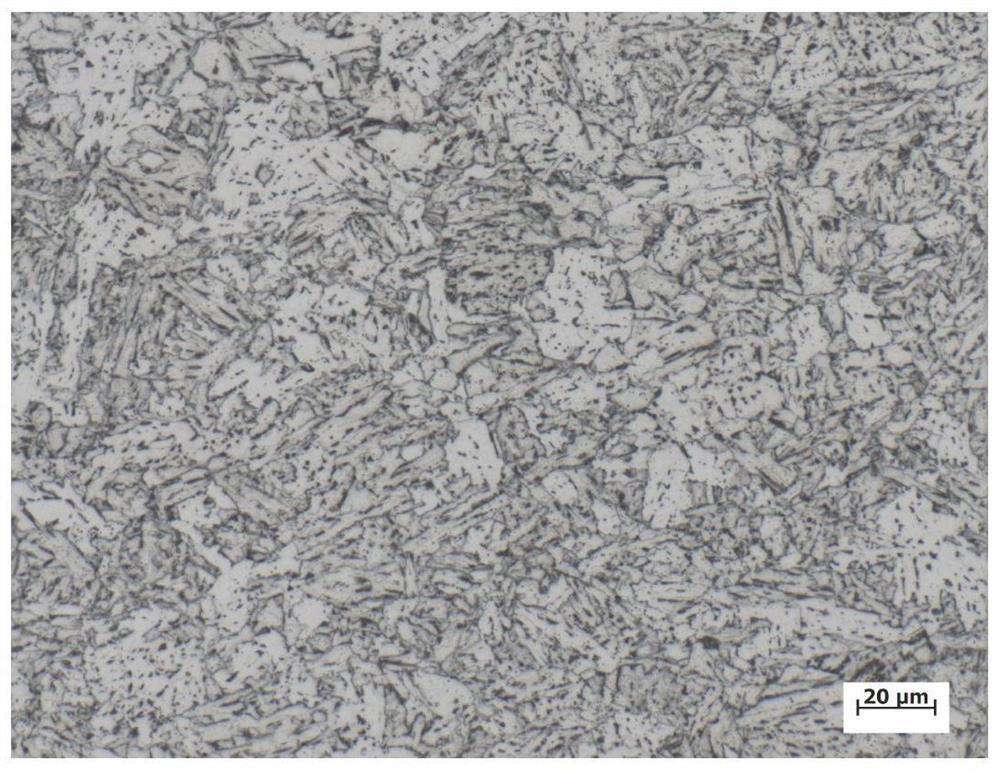

Embodiment 3

[0040] A 100mm-thick anti-seismic fire-resistant steel plate with a yield strength of 460MPa, the mass percentage of each element in its chemical composition is: C: 0.110%, Si: 0.38%, Mn: 0.95%, P: 0.011%, S: 0.007%, Cr: 0.65% , Mo: 0.20%, Nb: 0.092%, V: 0.015%, Ti: 0.028%, Al: 0.018%, N: 0.004%. The balance is Fe and unavoidable impurity elements. Its manufacturing method comprises the following process steps:

[0041] (1) Through the converter smelting process, the refining process outside the furnace, and the molten steel pouring continuous casting billet process, pouring into a billet with a thickness of 320 mm and a length of 3000 mm, the chemical composition of the billet is: C: 0.110%, Si: 0.38%, Mn: 0.95%, P: 0.011%, S: 0.007%, Cr: 0.65%, Mo: 0.21%, Nb: 0.099%, V: 0.015%, Ti: 0.028%, Al: 0.018%, N: 0.004%, The rest is Fe and unavoidable impurity elements.

[0042] (2) Heating process of the slab heating furnace: the heating temperature is 1180°C, and the furnace tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com