Non-selective oxidation vertical cavity surface emitting laser based on secondary epitaxy technology

A technology of vertical cavity surface emission and secondary epitaxy, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve problems such as AlGaAs layer cracking, affecting device performance, volume shrinkage, etc. effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

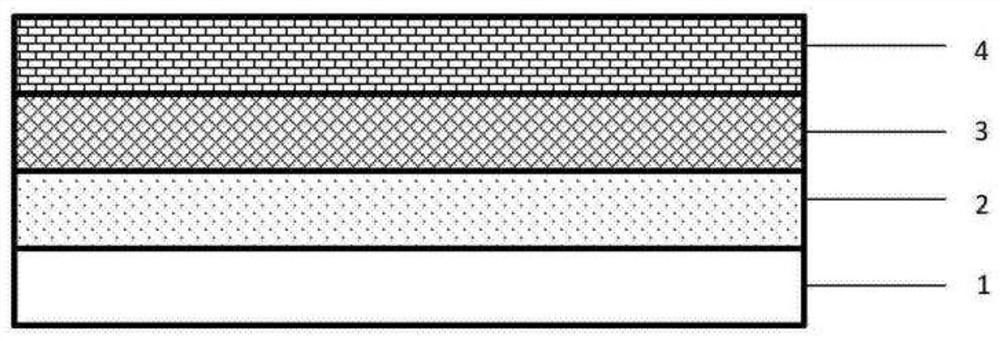

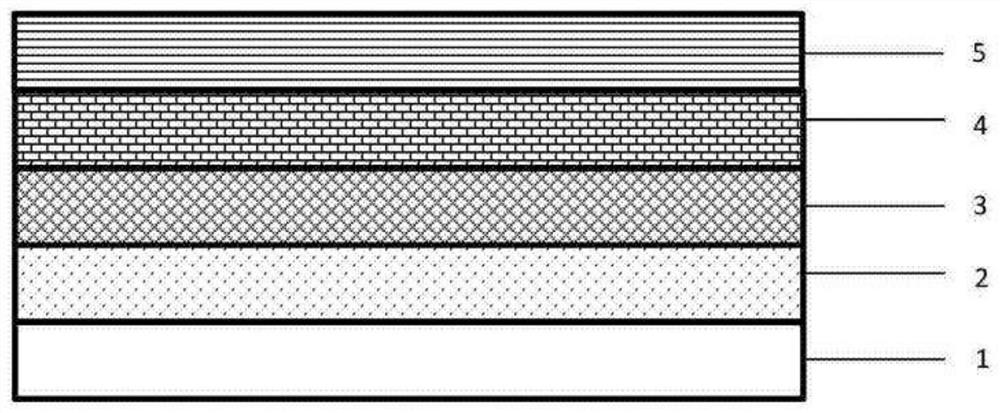

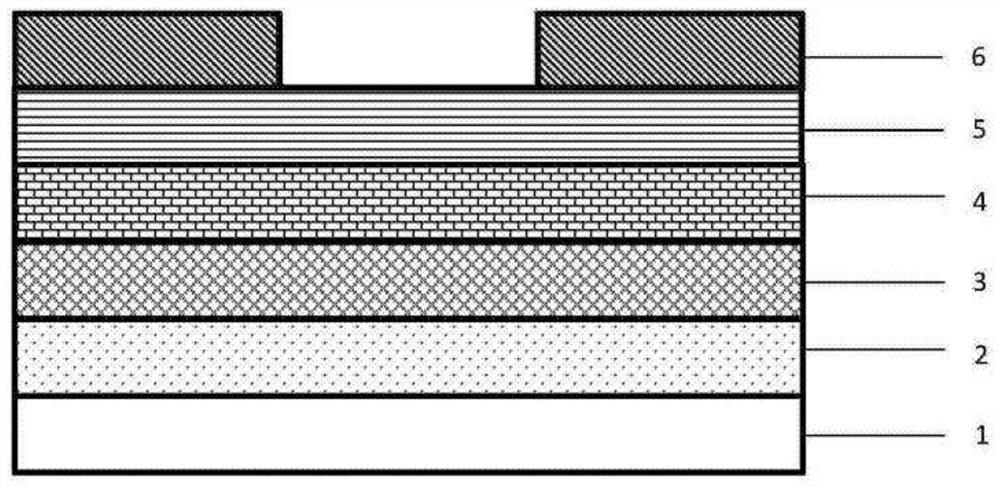

Method used

Image

Examples

Embodiment 1

[0037] After adding current to the laser made by the above-mentioned preparation method, the photons generated in the multi-quantum well layer 4 will be reflected back and forth before the N-type DBR layer 3 and the P-type DBR layer 8, because the hole-shaped Al 2 o 3 The refractive index of the thin film layer 7 is smaller than that of the P-type DBR layer 8. According to the waveguide theory of light and the principle of total reflection in the light transmission process, the laser light will only be limited to the hole-shaped Al 2 o 3 There is no Al in the middle of the film layer 7 2 o 3 position of the film, eventually along the middle without Al 2 o 3 The position of the film is lased out from the upper surface. Its schematic diagram is as follows Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com