Moisture-proof and anti-oxidation edible coating film for dried fruit and its preparation method and application

An anti-oxidation and dried fruit technology, applied in application, food science, food preservation, etc., can solve the problem of not containing antibacterial, anti-oxidative components, and oxidation of nutrients in difficult-to-dry fruits, achieve high antioxidant and bacteriostatic activities, and prevent absorption. Moisture, good moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

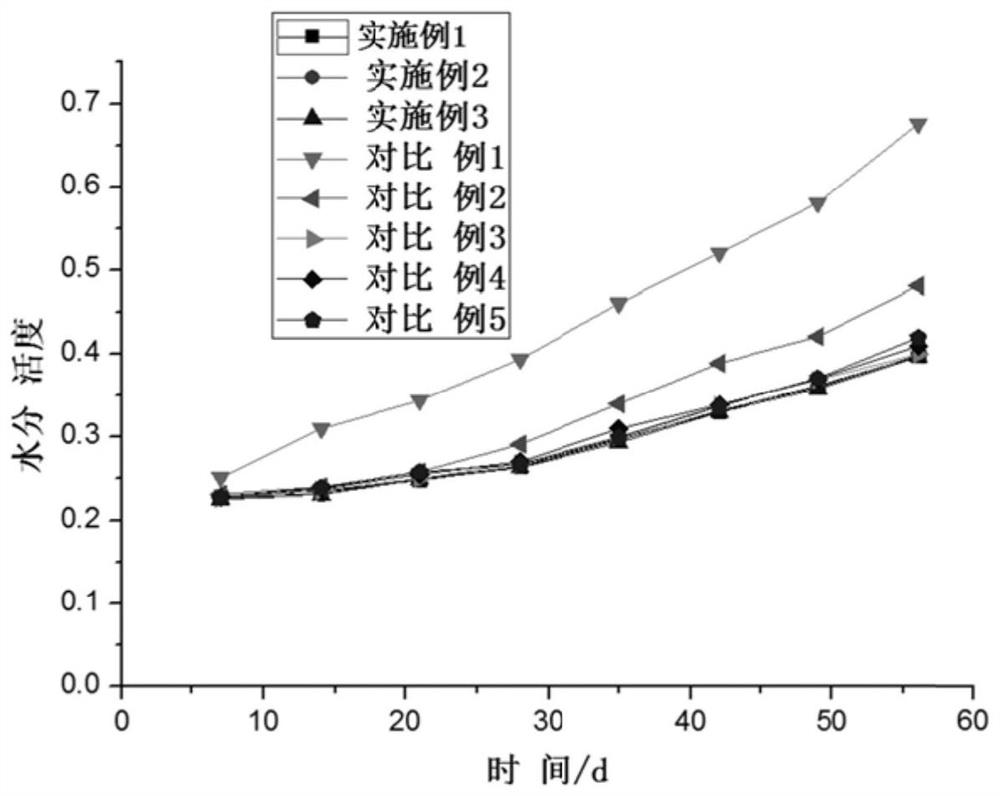

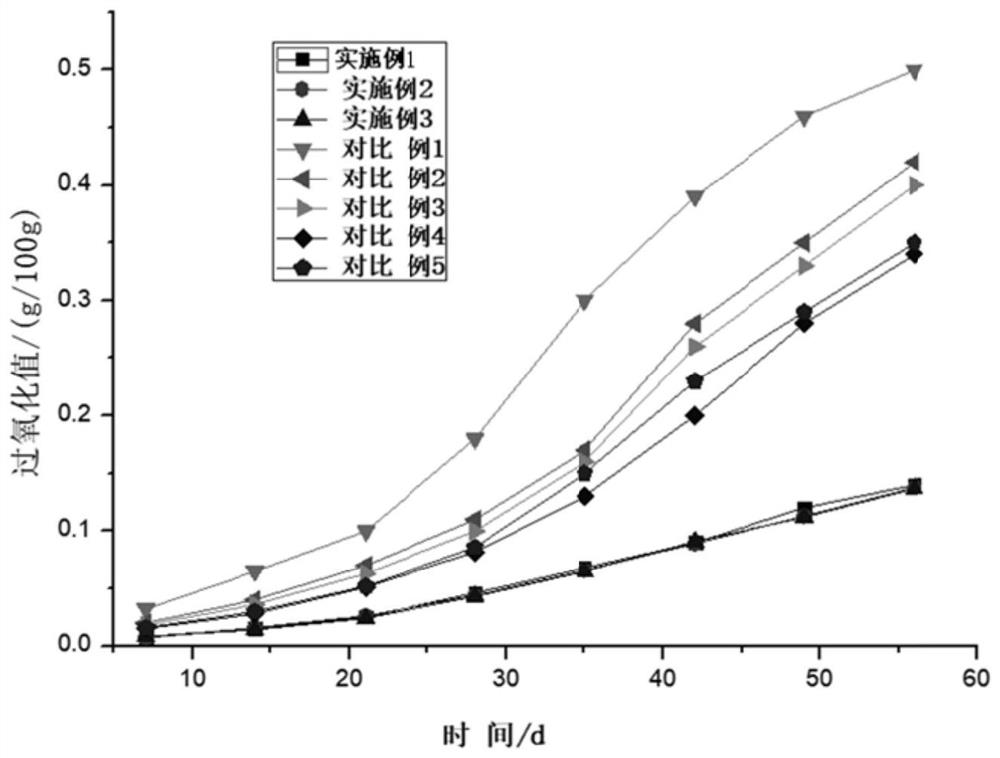

Examples

Embodiment 1

[0034] (1) Take the dried hawthorn fruit and grind it, pass through a 50-mesh sieve to obtain hawthorn powder. Take hawthorn powder, add distilled water according to the ratio of material to liquid 1:30 (g / mL), adjust the pH value to 2 with 1mol / L hydrochloric acid, reflux extraction at 90°C for 2 hours, filter, collect the filtrate, and take the filter residue to repeat the extraction once. The two extraction filtrates were combined, concentrated in vacuo until the pectin content was 20 mg / mL, and the hawthorn extract solution was obtained.

[0035] (2) Take dried rosebuds and crush them through a 40-mesh sieve, use 75% (mL / mL) ethanol aqueous solution as a solvent, and extract at 90°C for 2 hours at a material-to-liquid ratio of 1:15 (g / mL), filter, and repeat the extraction for 2 hours. The second time, the filtrates were combined, concentrated under reduced pressure, and dried in a vacuum oven at 50°C to obtain rose flower extract.

[0036](3) Take the peeled chestnut ker...

Embodiment 2

[0040] (1) Take the dried hawthorn fruit and crush them, pass through a 55-mesh sieve to obtain hawthorn powder. Take hawthorn powder, add distilled water according to the ratio of material to liquid 1:30 (g / mL), adjust the pH value to 2 with 1mol / L hydrochloric acid, reflux extraction at 90°C for 2 hours, filter, collect the filtrate, and take the filter residue to repeat the extraction once. The two extraction filtrates were combined, concentrated in vacuo until the pectin content was 15 mg / mL, and the hawthorn extract solution was obtained.

[0041] (2) Take dried rosebuds and crush them through a 45-mesh sieve, use 80% (mL / mL) ethanol aqueous solution as a solvent, and extract at 80°C for 2 hours at a material-to-liquid ratio of 1:15 (g / mL), filter, and repeat the extraction for 2 hours. The second time, the filtrates were combined, concentrated under reduced pressure, and dried in a vacuum oven at 50°C to obtain rose flower extract.

[0042] (3) Take the peeled chestnut ...

Embodiment 3

[0046] (1) Take the dried hawthorn fruit and crush them, pass through a 60-mesh sieve to obtain hawthorn powder. Take hawthorn powder, add distilled water according to the ratio of solid to liquid 1:30 (g / mL), adjust the pH value to 2 with 1mol / L hydrochloric acid, extract at 90°C for 2 hours, filter, collect the filtrate, and take the filter residue to repeat the extraction once. The two extraction filtrates were combined, concentrated in vacuo until the pectin content was 18 mg / mL, and the hawthorn extract solution was obtained.

[0047] (2) Take dried rosebuds and crush them through a 40-mesh sieve, use 75% (mL / mL) ethanol aqueous solution as a solvent, and extract at 85°C for 2 hours at a material-to-liquid ratio of 1:15 (g / mL), filter, and repeat the extraction for 2 hours. The second time, the filtrates were combined, concentrated under reduced pressure, and dried in a vacuum oven at 50°C to obtain rose flower extract.

[0048] (3) Take the peeled chestnut kernels and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com