Method and device for manufacturing nanofiltration membrane

A technology for manufacturing devices and manufacturing methods, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult large-scale and continuous production requirements of device technology, increased roll diameter, low viscosity, etc., to achieve Improve structural stability and continuous operation stability, uniformity in the width direction, and uniform pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

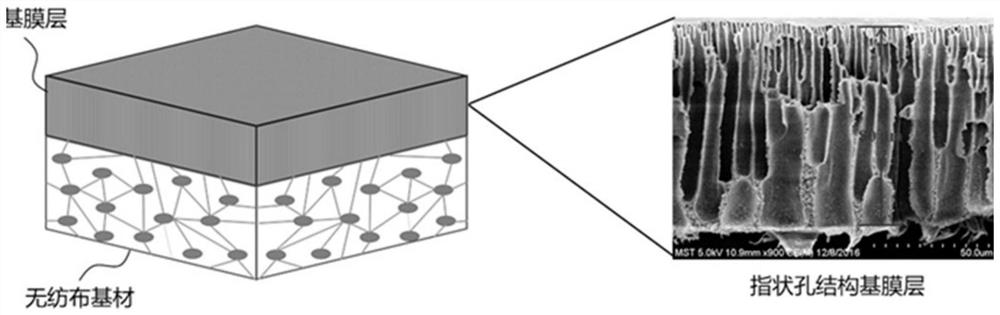

[0071] In the technical scheme of the present invention, firstly, a base film layer of a nanofiltration membrane is prepared continuously, stably and uniformly by adjusting the components of the casting liquid and forming a film through slit extrusion spraying, so as to meet the needs of large-scale production .

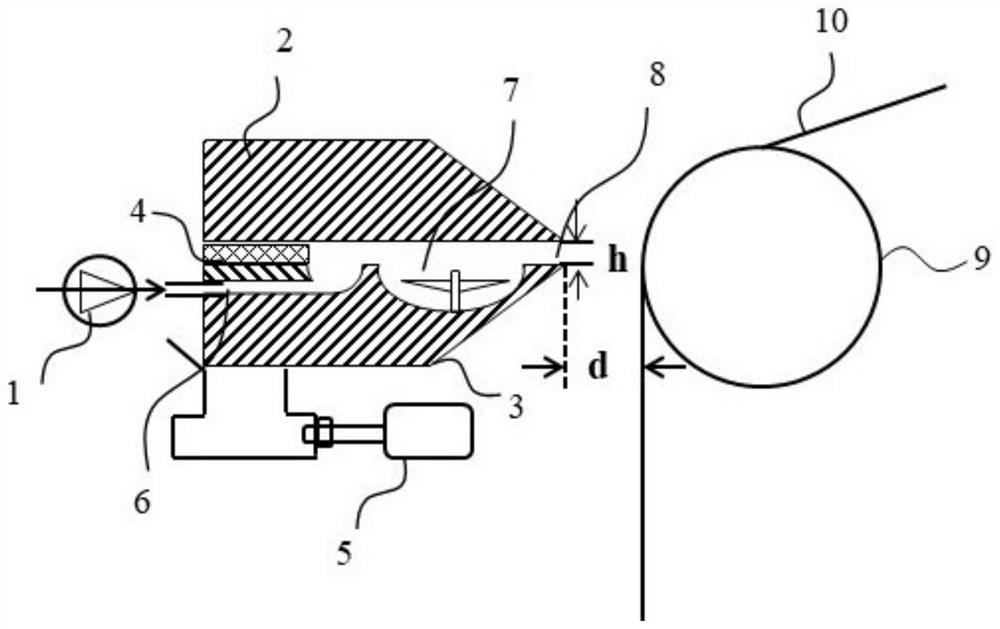

[0072] The slit coating equipment used for the large-scale preparation of the nanofiltration membrane base layer is as follows: figure 1 shown, including:

[0073] The slit spraying die is used to apply the coating liquid to the surface of the base film 10, and the slit spraying die is connected to the liquid storage tank through a metering pump 1;

[0074] Among them, the slit spraying die is composed of multiple parts, which are used to coat the surface of the flat base film. Therefore, the slit spraying die is in the shape of a strip as a whole. figure 1 Shown in is its cross-section, including:

[0075] The main part 2 of the upper film lip and the main part 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com