Low-cost titanium alloy short-process rolling process

A titanium alloy, short-process technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of limited popularization and application, reduction of comprehensive performance such as welding and fatigue, and high cost of titanium alloy plates, so as to shorten the process flow , eliminate the difference in tissue performance, and inhibit the effect of coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

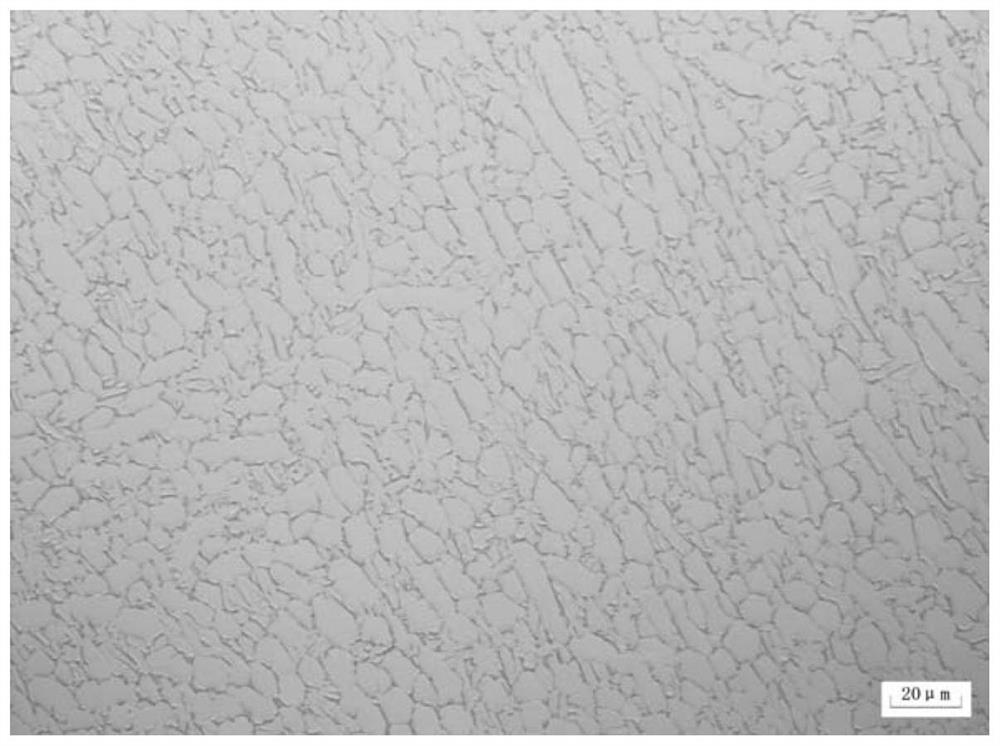

Embodiment 1

[0035] The concrete steps that adopt the inventive method to prepare the TC4 titanium alloy sheet material that thickness is 5mm are:

[0036] Step 1: The TC4 titanium alloy 200mm thick slab ingot prepared by electron beam cold bed furnace melting that passed the chemical composition inspection is kept in a heating furnace at 90°C above the β transformation point for 180min, and then the first hot rolling is carried out for 6 passes Keep the rolling direction of the first hot rolling as unidirectional rolling, the deformation of each pass is respectively: 15%, 20%, 20%, 25%, 20%, 15%, and then immerse in water and quickly cool to room temperature, Obtaining an intermediate slab with a thickness of 55 mm through surface grinding;

[0037] Step 2: After the first hot-rolled slab described in step 1 is kept in a heating furnace at 35°C below the β transformation point for 70 minutes, the second fire rolling is carried out for 5 passes, and the rolling direction of the first 3 pas...

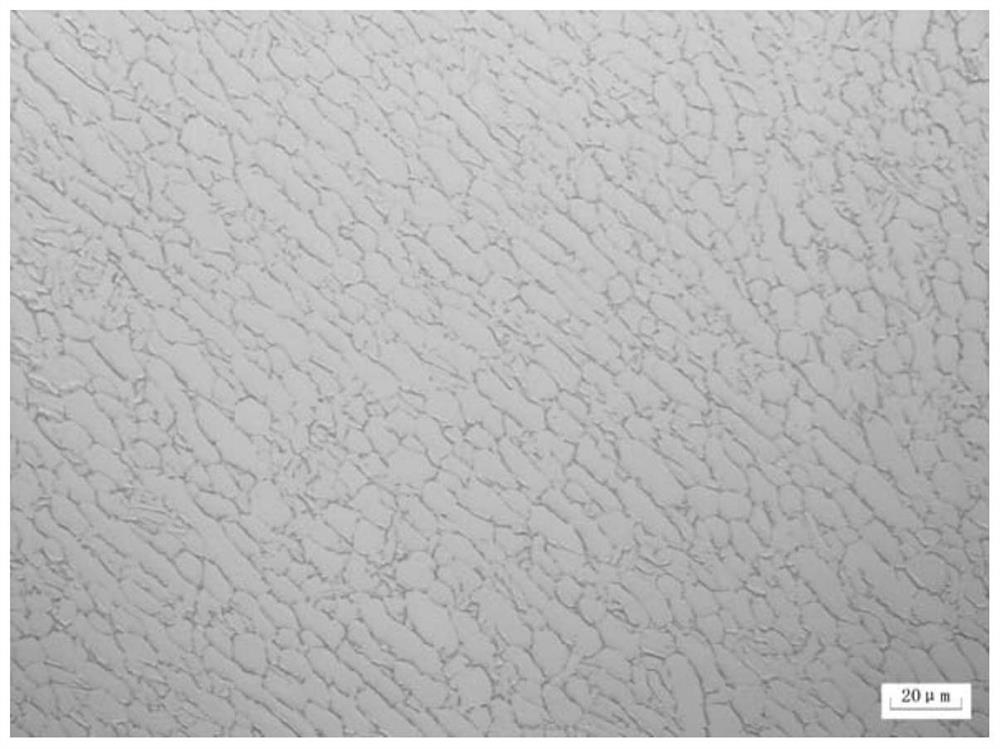

Embodiment 2

[0043] The concrete steps of the TC4 titanium alloy sheet material that adopts the inventive method to prepare thickness to be 8mm:

[0044] Step 1: The TC4 titanium alloy 220mm thick slab ingot prepared by electron beam cold bed furnace melting that passed the chemical composition inspection was kept in a heating furnace at 120°C above the β transformation point for 200 minutes, and then carried out 7 passes of the first hot rolling Keep the rolling direction of the first hot rolling as unidirectional rolling, the deformation of each pass is: 12%, 15%, 20%, 20%, 20%, 12%, 12%, and then immerse in water for rapid cooling After reaching room temperature, a middle slab with a thickness of 65 mm was obtained through surface grinding.

[0045] Step 2: heat the first hot-rolled slab described in step 1 in a heating furnace at 45°C below the β transformation point for 80 minutes, and then perform 6 passes of second fire rolling, wherein the rolling direction of the first 3 passes is...

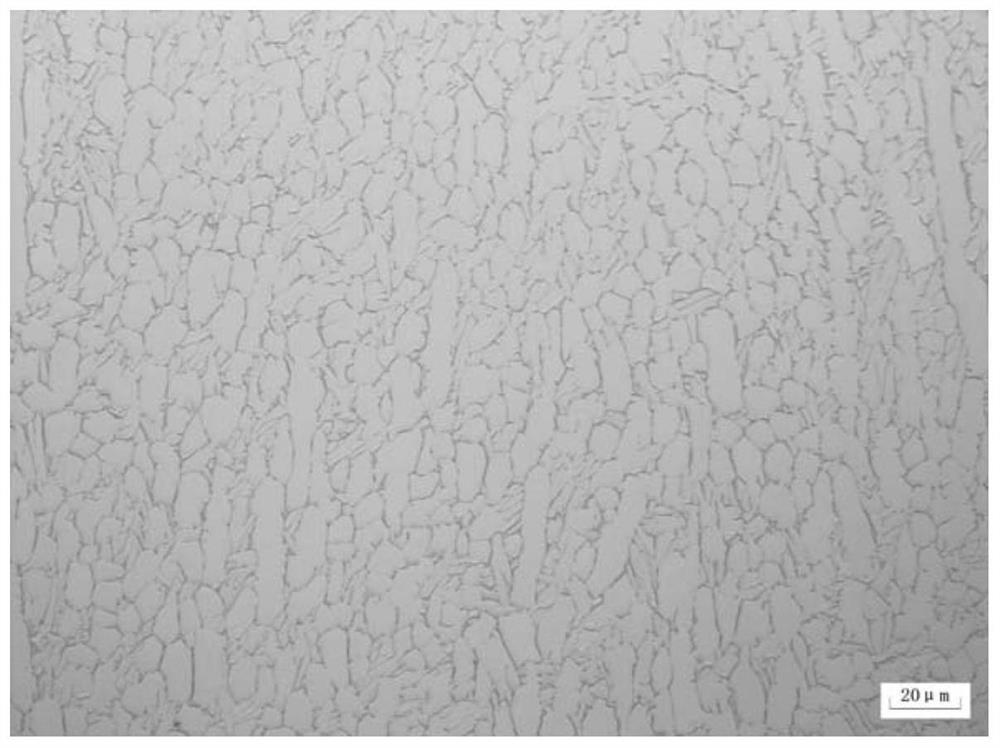

Embodiment 3

[0051] The concrete steps of the TC4 titanium alloy sheet material that adopts the inventive method to prepare thickness to be 10mm:

[0052] Step 1: The TC4 titanium alloy 250mm thick slab ingot prepared by electron beam cold bed furnace melting that passed the chemical composition test was kept in a heating furnace at 150°C above the β transformation point for 240min, and then carried out 7 passes of the first hot rolling Keep the rolling direction of the first hot rolling as unidirectional rolling, the deformation of each pass is: 12%, 15%, 20%, 20%, 20%, 12%, 11%, and then immerse in water for rapid cooling After reaching room temperature, a middle slab with a thickness of 75 mm was obtained through surface grinding.

[0053] Step 2: heat the first hot-rolled slab described in step 1 in a heating furnace at 60°C below the β transformation point for 90 minutes, and then perform 4 passes of second fire rolling, wherein the rolling direction of the first 2 passes is It is pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com