Sound absorbing material and preparation method thereof

A sound-absorbing material and sound-absorbing layer technology, applied in the field of sound-absorbing materials, can solve the problems of single function and low sound absorption coefficient, and achieve the effects of saving resources, small thermal conductivity, good chemical stability and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

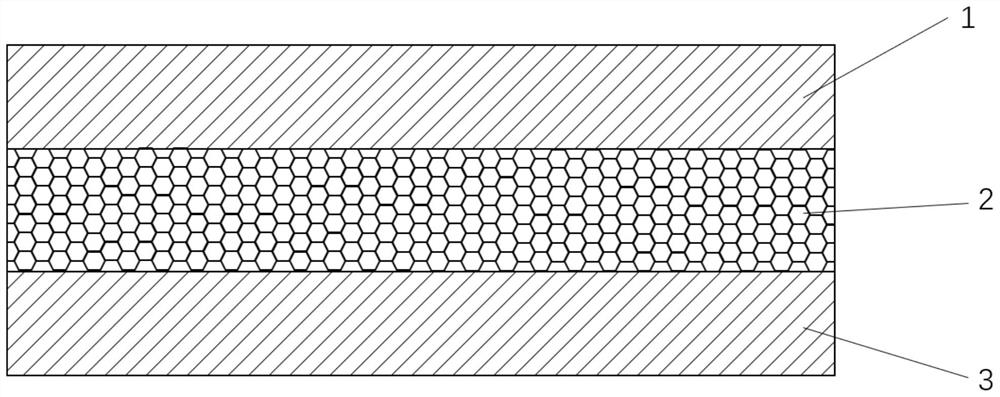

[0033] A sound-absorbing material, which consists of upper, middle and lower parts, of which the upper and lower layers are sound-absorbing layers, and the middle layer is a sound-insulating layer.

[0034] The sound-absorbing layer is slag wool.

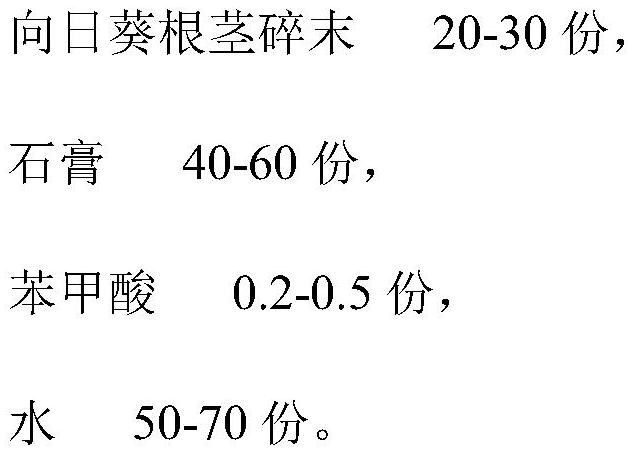

[0035] The sound insulation layer is made of the following raw materials in parts by weight:

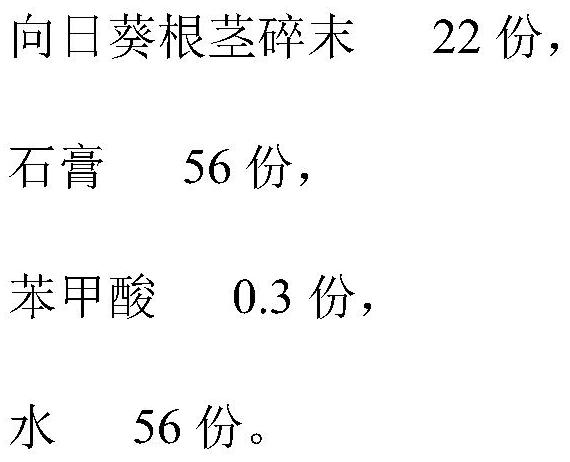

[0036] 22 portions of minced sunflower rhizomes,

[0037] 56 parts of gypsum,

[0038] 0.3 parts of benzoic acid,

[0039] 56 parts of water.

[0040] The sound insulation layer is prepared by the following steps:

[0041] (1) Put the sunflower rhizome into a pulverizer for crushing, put the crushed sunflower rhizome in an oven to dry for 24 hours to remove moisture, set the temperature to 110° C., and finally have a moisture content of <9.9%;

[0042] (2) After drying, use a 200-mesh sieve to sieve the crushed sunflower rhizomes, mix and stir the sifted rhizomes with gypsum water, add a benzoic acid preservative during the mixing pro...

Embodiment 2

[0049] A sound-absorbing material, which consists of upper, middle and lower parts, of which the upper and lower layers are sound-absorbing layers, and the middle layer is a sound-insulating layer.

[0050] The sound-absorbing layer is slag wool.

[0051] The sound insulation layer is made of the following raw materials in parts by weight:

[0052] 25 parts of sunflower rhizome mince,

[0053] 50 parts of gypsum,

[0054] 0.5 parts of benzoic acid,

[0055] 60 parts of water.

[0056] The sound insulation layer is prepared by the following steps:

[0057] (1) Put the sunflower rhizome into a pulverizer for crushing, put the crushed sunflower rhizome in an oven to dry for 24 hours to remove moisture, set the temperature to 110° C., and finally have a moisture content of <9.9%;

[0058] (2) After drying, use a 200-mesh sieve to sieve the crushed sunflower rhizomes, mix and stir the sifted rhizomes with gypsum water, add a benzoic acid preservative during the mixing process,...

Embodiment 3

[0065] A sound-absorbing material, which consists of upper, middle and lower parts, of which the upper and lower layers are sound-absorbing layers, and the middle layer is a sound-insulating layer.

[0066] The sound-absorbing layer is slag wool.

[0067] The sound insulation layer is made of the following raw materials in parts by weight:

[0068] 30 portions of minced sunflower rhizomes,

[0069] 60 parts of gypsum,

[0070] 0.4 parts of benzoic acid,

[0071] 65 parts of water.

[0072] The sound insulation layer is prepared by the following steps:

[0073] (1) Put the sunflower rhizome into a pulverizer to pulverize, put the pulverized sunflower rhizome in an oven to dry for 24 hours to remove moisture, set the temperature to 105° C., and finally have a moisture content of <9.9%;

[0074] (2) After drying, use a 200-mesh sieve to sieve the crushed sunflower rhizomes, mix and stir the sifted rhizomes with gypsum water, add a benzoic acid preservative during the mixing pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap