Low-density foam concrete and preparation method thereof

A foamed concrete, low-density technology, applied in the field of building insulation materials, can solve the problems of only focusing on compression resistance, complex preparation process, and many kinds of raw materials, and achieve the effects of uniform bubble size, simple preparation method and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

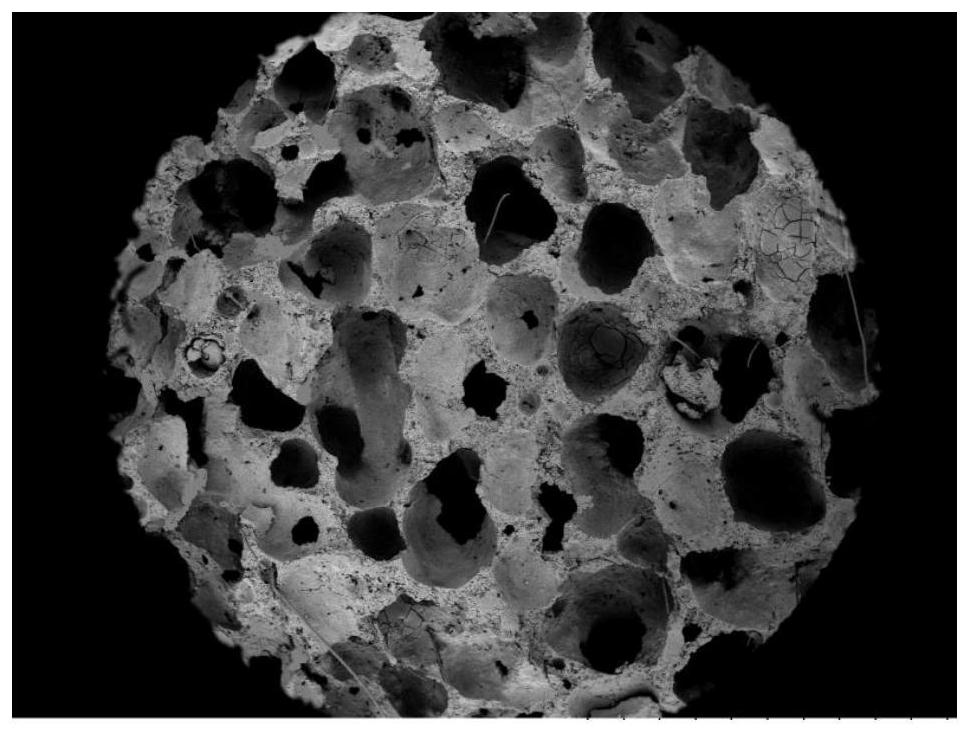

Image

Examples

preparation example Construction

[0018] The present invention also provides a preparation method for the above-mentioned low-density foamed concrete, comprising the following steps: (1) accurately weighing various components by weight; (2) mixing ordinary Portland cement, fly ash, silica fume, high Aluminum cement, foam stabilizer, rubber powder, and fiber are stirred for 1min to 2min; (3) Add water and water reducer (the water reducer is dissolved in water in advance) and stir for 1min to 2min; (4) Add foaming agent and stir for 10s to 15s (4) pouring into the mold, curing at room temperature to get foam concrete.

[0019] In the formula of the present invention, ordinary Portland cement, fly ash and silica fume are used as cementing materials; hydrogen peroxide is used as a foaming agent for chemical foaming; rubber powder can improve the cohesion, cohesion and flexibility of the slurry, and reduce cracking The foam stabilizer sodium stearate or calcium stearate can increase the viscosity of the slurry, imp...

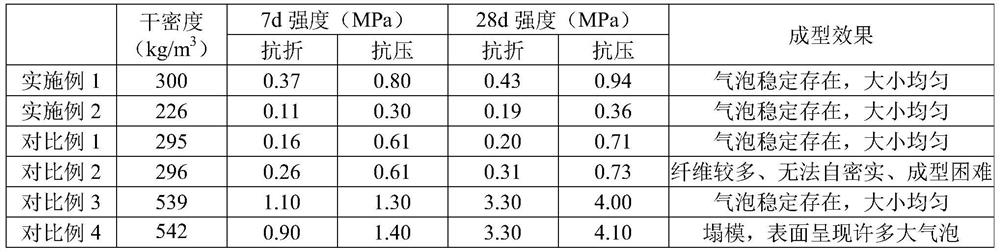

Embodiment 1

[0023] Raw materials: 690 parts of ordinary Portland cement, 200 parts of fly ash, 60 parts of silica fume, 50 parts of high alumina cement, 60 parts of foaming agent hydrogen peroxide, 10 parts of foam stabilizer sodium stearate, 2 parts of rubber powder, poly 3 parts of vinyl alcohol fiber, 10 parts of water reducing agent, 500 parts of water;

[0024] The preparation method is as follows:

[0025] (1) Accurately weigh each component by weight;

[0026] (2) Mix the weighed ordinary Portland cement, fly ash, silica fume, high alumina cement, foam stabilizer sodium stearate, rubber powder and polyvinyl alcohol fiber for 1 min;

[0027] (3) Add water and water reducer (water reducer dissolved in water in advance) and stir for 1 min;

[0028] (4) Add foaming agent and stir for 15s;

[0029] (5) Pour into the mold, and cure at room temperature to obtain foam concrete.

Embodiment 2

[0031] Raw materials: 690 parts of ordinary Portland cement, 200 parts of fly ash, 60 parts of silica fume, 50 parts of high alumina cement, 70 parts of foaming agent hydrogen peroxide, 20 parts of foam stabilizer calcium stearate, 3 parts of rubber powder, wood 1.5 parts of fiber, 1.5 parts of polypropylene fiber, 9 parts of water reducing agent, 550 parts of water;

[0032] The preparation method is as follows:

[0033] (1) Accurately weigh each component by weight;

[0034] (2) Mix the weighed ordinary Portland cement, fly ash, silica fume, high alumina cement, foam stabilizer calcium stearate, rubber powder, wood fiber and polypropylene fiber for 1 min;

[0035] (3) Add water and water reducer (water reducer dissolved in water in advance) and stir for 1 min;

[0036] (4) Add foaming agent and stir for 15s;

[0037] (5) Pour into the mold, and cure at room temperature to obtain foam concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com