Novel plate and production process thereof

A new type of panel and production process technology, applied in floor covering, layered products, building insulation materials, etc., can solve the problems of panel strength decline, poor corrosion resistance, easy moisture absorption, etc., achieve long service life, convenient construction, high The effect of bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

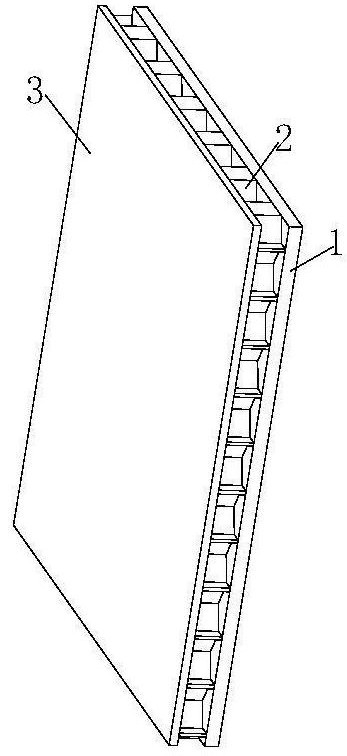

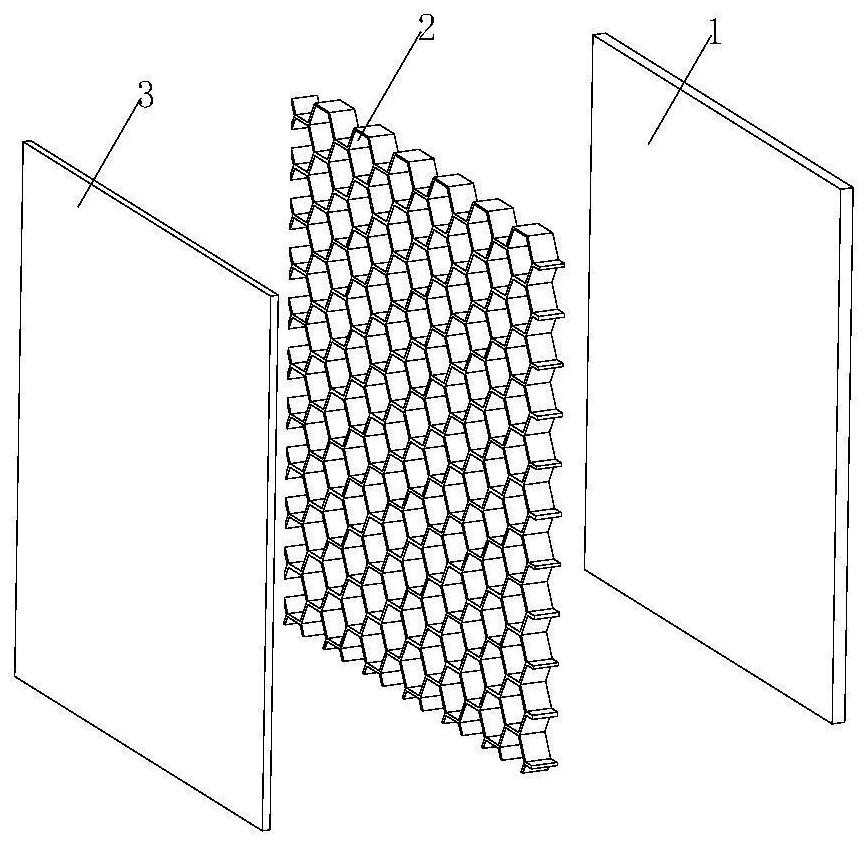

[0034] A new type of plate, see Figure 1 to Figure 4 , including: magnesium oxide composite panel 1, honeycomb metal mesh 2 and metal bottom plate 3, one side of the honeycomb metal mesh 2 is set on the surface of the metal bottom plate 3, and the other side of the honeycomb metal mesh 2 is set on the surface of the magnesium oxide composite panel 1 surface. The honeycomb metal mesh 2 is a plate structure, and its honeycomb is a hexagonal honeycomb. The magnesium oxide composite panel in this embodiment has the characteristics of fire prevention, waterproof, odorless, non-toxic, non-freezing, non-corrosion, non-cracking, unchanged, non-combustible, high-strength, light-weight, convenient construction, and long service life; the honeycomb metal mesh Located between the magnesium oxide composite panel and the metal base plate, the sandwich structure can withstand shear stress, so that this new type of plate has high bending rigidity and improves structural strength. The metal...

Embodiment 2

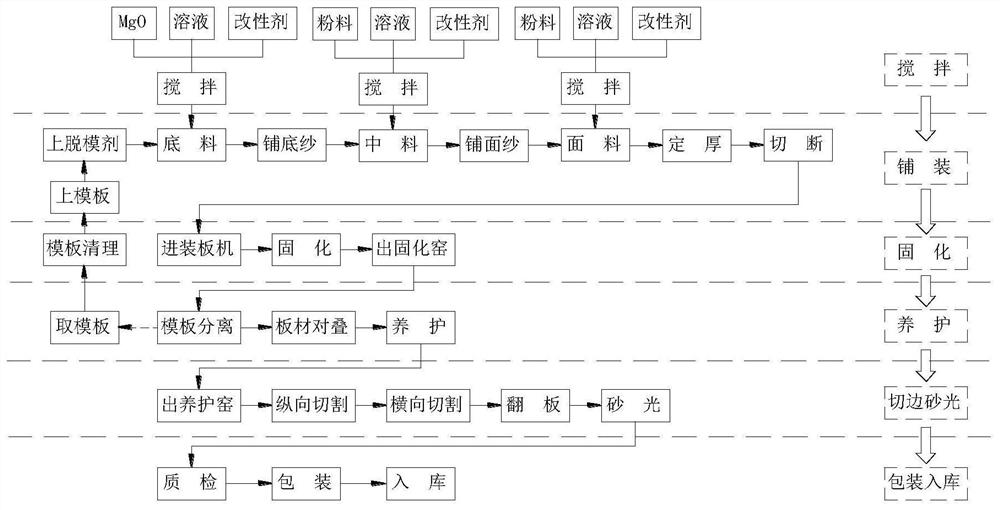

[0051] For the production process of the new plate, please refer to image 3 , produce the novel sheet material as embodiment 1, wherein the production technique of magnesium oxide composite panel 1 comprises the steps:

[0052] S1. After coating the mold release agent on the template, coat the base material, lay the bottom yarn, coat the middle material, spread the veil, coat the fabric, set the thickness, and cut the material;

[0053] S2. Enter the loading machine, enter the curing kiln, fix, and exit the curing kiln;

[0054] S3. The formwork is separated, the plates are stacked, and they are put into the curing kiln for curing;

[0055] S4. Out of the curing kiln, longitudinal cutting, horizontal cutting, flipping, sanding;

[0056] S5. Quality inspection, packaging, storage.

[0057] The base yarn and the veil in step S1 can be non-woven fabrics.

[0058] Preferably, the template in step S1 comes from the template separated from the template in step S3 after cleaning...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap