Small skid-mounted waste plasma gasification melting treatment device

A technology of gasification melting and processing device, applied in the field of ion gasification melting processing device, can solve the problems such as inability to adapt to the new mode of waste source reduction, complex plasma gasification device system, and difficulty in realizing skid-mounted movement, etc. Automatic operation, small number of equipment, and satisfying the effect of skid-mounted arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

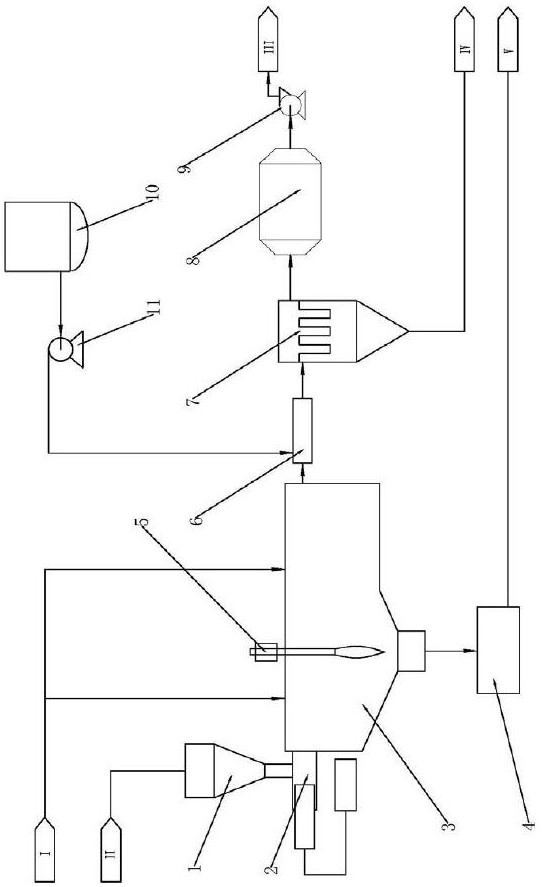

[0022] Such as figure 1 As shown, the small-sized skid-mounted waste plasma gasification melting treatment device provided in this embodiment includes a horizontal plasma gasification furnace 3, a cold slag bucket 4, a spray quencher 6, a bag filter 7, an activated carbon box 8 and Induced fan 9.

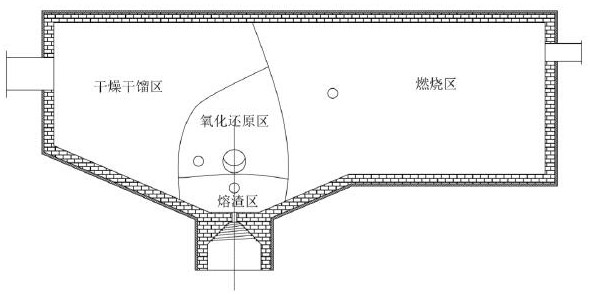

[0023] The furnace body of the horizontal plasma gasification furnace 3 is arranged horizontally, the two sides of the side wall of the furnace body are respectively provided with a feed inlet and a flue gas outlet, the bottom of the furnace body is provided with a slag outlet, and the furnace body wall is provided with a Plasma torch5. Such as figure 2 As shown, the hearth of the horizontal plasma gasifier 3 is divided into a dry distillation zone, a redox zone, a slag zone, and a combustion zone. The dry distillation zone is located at the side of the feed inlet, and the redox zone is adjacent to the dry distillation zone Located in the area where the plasma torch 5 is located...

Embodiment 2

[0027] On the basis of embodiment 1, according to the moving direction of the raw material II entering the furnace, the raw material enters the dry distillation zone after entering the furnace from the feed port, and enters the redox zone after being dried and carbonized in the dry distillation zone. Oxidation-reduction reaction, after the oxidation-reduction reaction, it enters the combustion zone for full combustion; the inorganic matter in the raw material is melted into a liquid state and flows out from the slag outlet, and the organic matter in the raw material is dry-distilled, pyrolyzed, and oxidized to form carbon dioxide and The high-temperature flue gas of water vapor; the flue gas outlet is connected to the spray quencher 6 and the bag filter 7 to purify the high-temperature flue gas, and the purified flue gas III is discharged again.

Embodiment 3

[0029] On the basis of Embodiment 1 or 2, the feed port of the horizontal plasma gasifier 3 is connected with a funnel-shaped feed bin 1, and a push feeder 2 is arranged between the feed bin 1 and the feed port, The push feeder 2 pushes the raw material through the feed push rod.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap