Method for simulating laser powder bed melting process by using lattice Boltzmann method based on Python

A simulation method and melting process technology, applied in design optimization/simulation, CAD numerical modeling, instruments, etc., can solve problems such as immature commercial software and occupation of computing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] The present invention adopts following technology in a kind of numerical simulation method that uses lattice Boltzmann method to carry out laser powder bed melting process based on Python:

[0043] 1. Numerical simulation method based on lattice Boltzmann method;

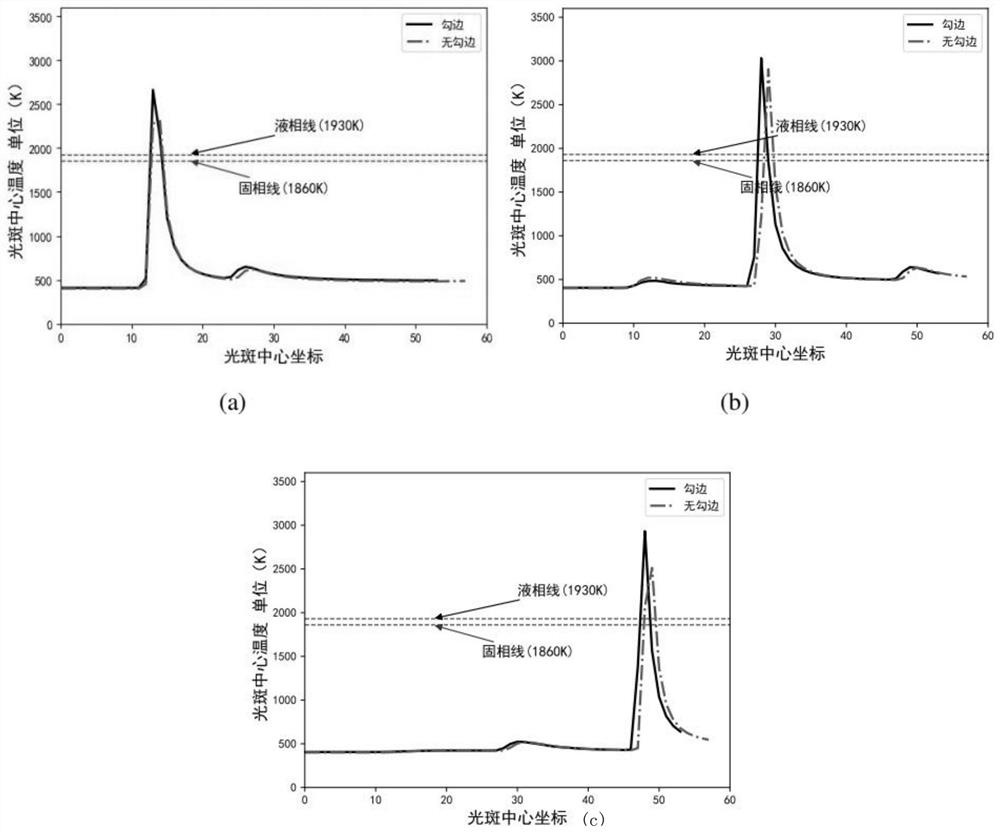

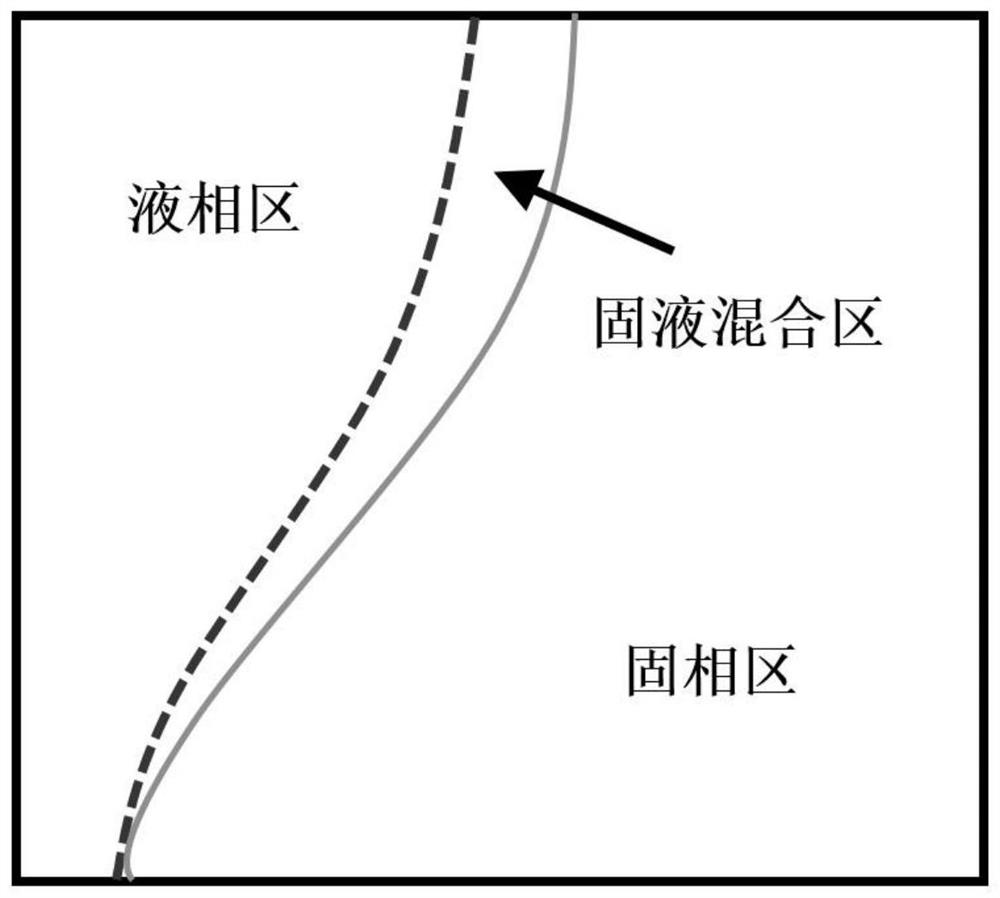

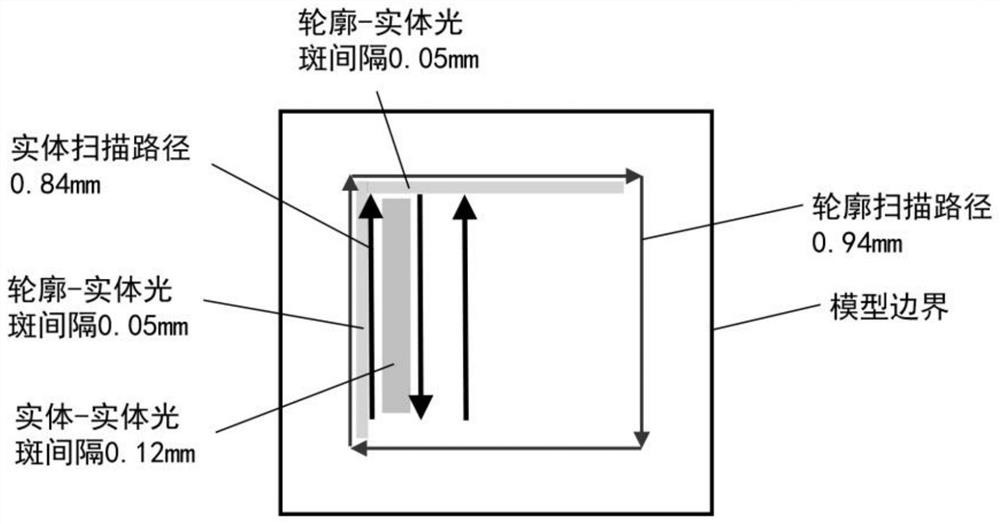

[0044] Different from the finite volume, finite element and finite difference methods used in the traditional laser powder bed melting numerical simulation, the numerical simulation method of the present invention adopts the lattice Boltzmann method, which solves mass, momentum and For the energy transfer problem, the difference from the traditional method is that the traditional CFD method needs to be based on the assumption of continuity and discretize the equation to be solved to nodes, units or volumes for solution, and its essence is to iteratively solve the differentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com