N-type bismuth telluride-based thermoelectric material and preparation method thereof

A technology based on bismuth telluride and thermoelectric materials, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems that restrict the development of p-type materials and thermoelectric devices, and increase the effective mass of electrons, Realization of ZT value and reduction of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] High-purity Bi, Te, Se particles according to Bi 2 Te 2.7 Se 0.3 The stoichiometric ratio is mixed and smelted. The smelting treatment includes: heating up to 600°C at a heating rate of 3°C / min, holding for 1 hour, then raising the temperature to 850°C at a heating rate of 1.5°C / min, holding for 5 hours, and then furnace cooling to room temperature, Bi 2 Te 2.7 Se 0.3 Ingot.

[0048] Bi 2 Te 2.7 Se 0.3 After the ingot was pre-ground, it was mixed with 5wt% high-purity Sb particles, and ball milled at 450r / min for 10h to obtain Bi 2 Te 2.7 Se 0.3 +5 wt% Sb powder.

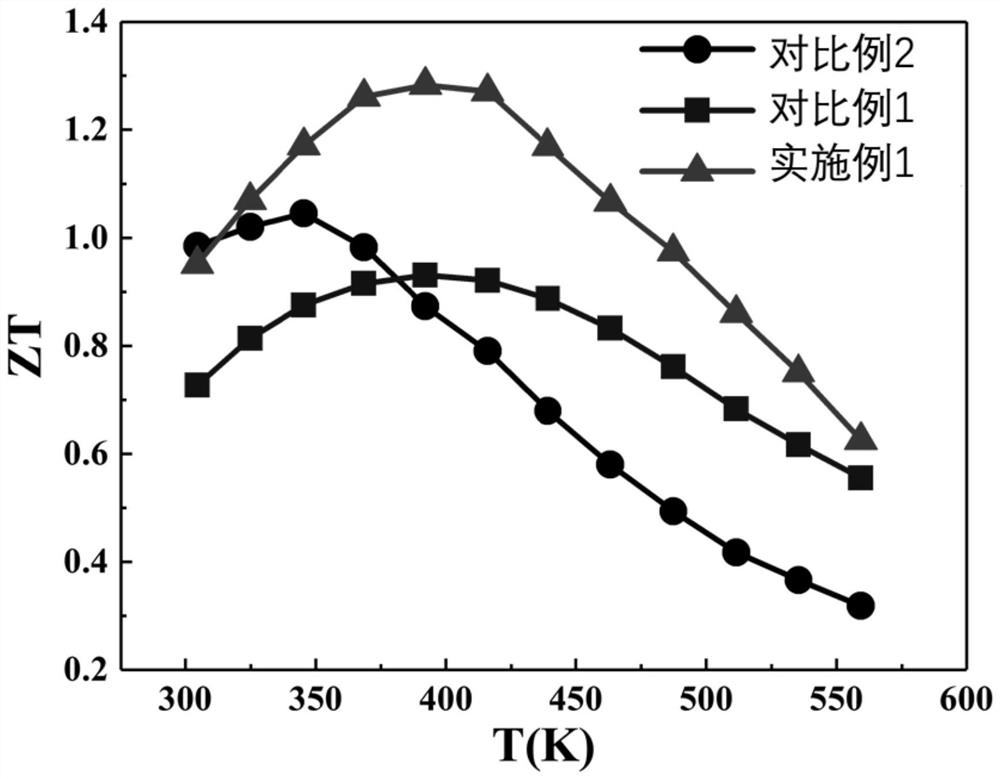

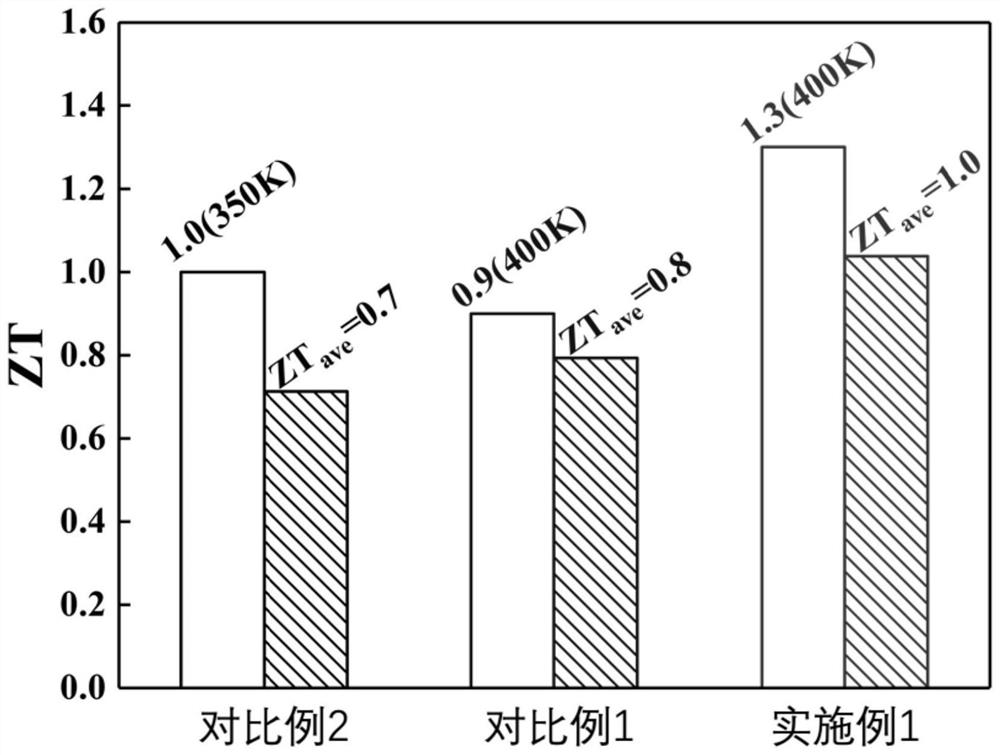

[0049] the Bi 2 Te 2.7 Se 0.3 +5wt% Sb powder was subjected to spark plasma sintering, the sintering temperature was 450°C, the sintering pressure was 50MPa, and the sintering time was 5min, and a columnar block of Φ10*10 was prepared. After cutting, the maximum ZT value is 1.3 (400K), and the average ZT value is ZT ave It is 1.0 (300 ~ 575K).

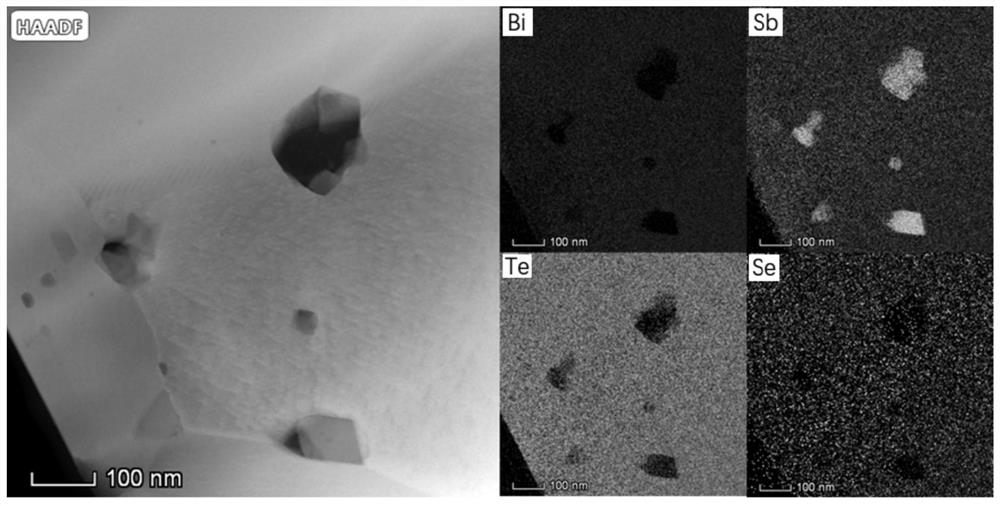

[0050] The prepared product was characterized b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com