Power battery equalization and heating composite circuit based on LC resonance and conductive film

A power battery and composite circuit technology, which is applied in the direction of charge equalization circuit, battery circuit device, circuit, etc., can solve the problems of lower lithium battery performance, slow ion conduction speed, large current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

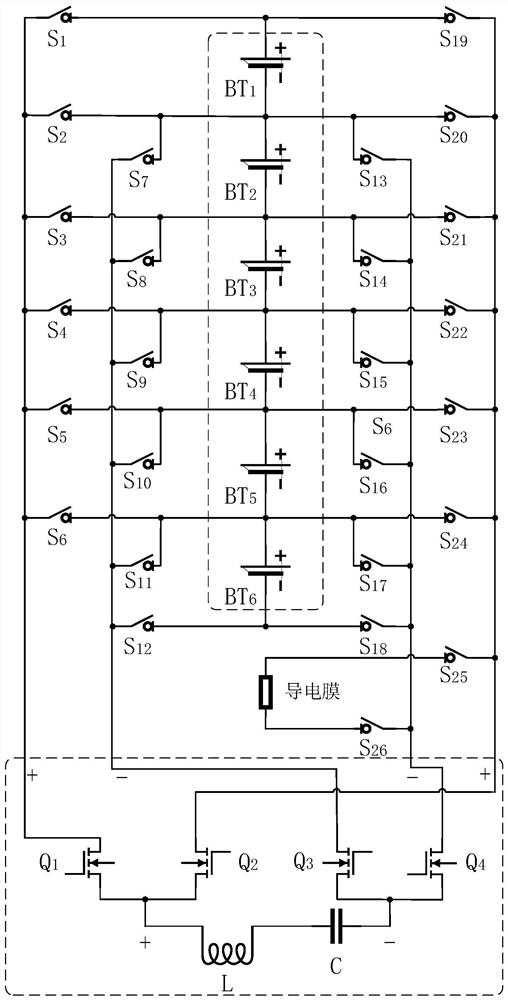

[0036] Such as figure 1 As shown, this embodiment is a power battery equalization and heating compound circuit (referred to as circuit) based on LC resonance and conductive film, including a battery pack, an LC resonance unit and a conductive film; the LC resonance unit includes an inductance L and a capacitor C connected in series ; The LC resonant unit leads to two positive connection terminals and two negative connection terminals, and one positive connection terminal is connected to the N-type MOS transistor Q 1 The source is connected, and the other positive connection is connected to the N-type MOS transistor Q 2 The drain connection, a negative connection terminal and N-type MOS transistor Q 3 The drain is connected, and the other negative terminal is connected to the N-type MOS transistor Q 4 source connection;

[0037] The battery pack includes six battery cells BT connected in series 1 ~BT 6 ;Battery unit BT 1 The positive pole of the relay S 1 With N-type MOS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com