Preparation method of methanol catalytic oxidation photoelectric catalyst

A catalytic oxidation, photoelectric catalysis technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to achieve enhanced light capability, increased current density, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

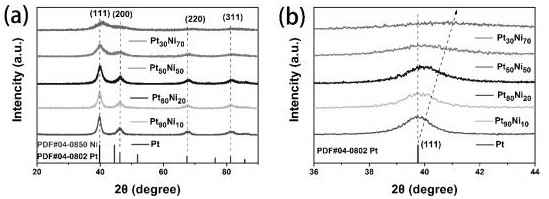

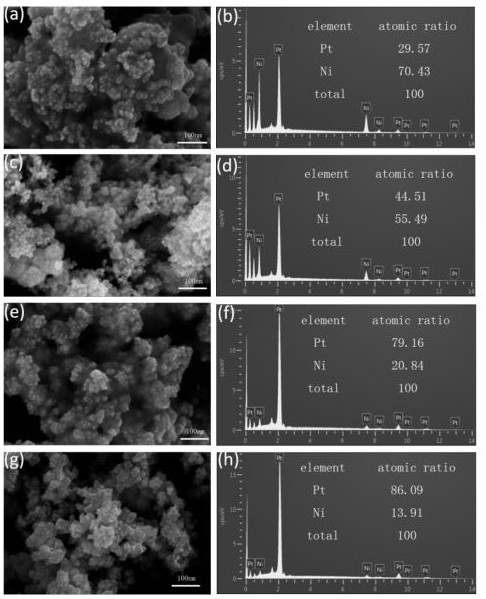

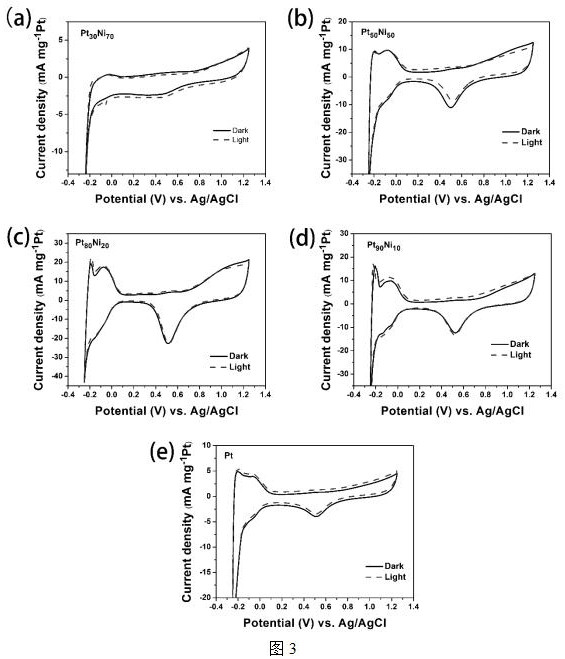

Embodiment 1

[0031] Pt 30 Ni 70 The preparation process of alloy nanoparticles is as follows:

[0032] Configure 20mM K 2 PtCl 4 solution, 20mM NiCl 2 ·6H 2 O solution, 2mg mL -1 TA (tannic acid) solution and 100mM NaBH 4 . Use a pipette gun according to the volume ratio of 3:7, take 20mM K 2 PtCl 4 Solution 1.8ml and 20mM NiCl 2 ·6H 2 Mix 4.2ml O solution in a 50mL round bottom flask, add 3ml 2mg mL -1 TA (tannic acid) solution. Put it into an ultrasonic machine for the first ultrasonic 30min (where the temperature is controlled in an ice bath -5°C-0°C); take 1.8ml 100mM NaBH 4 Immediately add to the above ultrasonic solution for the second ultrasonic 30min; after 30min, take out and wash repeatedly with deionized water and ethanol, and dry at 60°C for 12h to obtain Pt 30 Ni 70 Nano alloy materials.

Embodiment 2

[0034] Pt 50 Ni 50 The preparation process of alloy nanoparticles is as follows:

[0035] Configure the solution as in Example 1, use a pipette gun in a volume ratio of 1:1, and take 20mM K 2 PtCl 4 Solution 3ml and 20mM NiCl 2 ·6H 2 Mix 3ml of O solution in a 50mL round bottom flask, add 3ml of 2mg mL -1 TA solution. Put it into an ultrasonic machine for the first ultrasonic 30min (where the temperature is controlled in an ice bath -5°C-0°C); take 3ml 100mM NaBH 4 Immediately add the above ultrasonic solution to the second ultrasonic 30min; the subsequent washing and drying steps are the same as in Example 1.

Embodiment 3

[0037] Pt 80 Ni 20 The preparation process of alloy nanoparticles is as follows:

[0038] Configure the solution as in Example 1, use a pipette gun in a volume ratio of 4:1, and take 20mM K 2 PtCl 4 Solution 4.2ml and 20mM NiCl 2 ·6H 2 Mix 1.8ml O solution in a 50mL round bottom flask, add 3ml 2mg mL -1 TA solution. Put it into an ultrasonic machine for the first ultrasonic 30min (where the temperature is controlled in an ice bath -5°C-0°C); take 4.2ml 100mM NaBH 4 Immediately add the above ultrasonic solution to the second ultrasonic 30min; the subsequent washing and drying steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminescence spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com