Hydrogel bonding method, hydrogel bonded body and debonding method of hydrogel bonded body

A bonding method, the technology of hydrogel tape, applied in the field of polymer materials, can solve the problems of long-term cost, harsh trigger mechanism, etc., and achieve the effect of strong bonding, simple steps and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0052] A kind of acrylic acid-acrylamide copolymer (PAAc-co-PAAm) hydrogel adhesive tape, preparation method is as follows:

[0053] (1) Mix 12.97g acrylic acid, 4.26g acrylamide, 0.065g water-soluble azo initiator V-50, 0.228g silane coupling agent 3-(trimethoxysilyl) propyl acrylate and 120mL water Uniformly, forming a precursor solution; the precursor solution is irradiated under an ultraviolet lamp for 4 minutes to obtain a polymerization solution;

[0054] (2) Spin-coat the polymerization solution that step (1) obtains on the plexiglass plate, control the spin-coating speed to be 1000rpm, and the spin-coating time is 50s to obtain a pre-polymerized film;

[0055] (3) Place the pre-polymerized film obtained in step (2) in an HCl solution with a pH value of 3.5 for 5 minutes to complete cross-linking; then place the sample in a 65°C oven for 3 hours to obtain the PAAc-co-PAAm water Gel tape with a thickness of 5 μm.

[0056] The first hydrogel and the second hydrogel invo...

Embodiment 1

[0058] A method for bonding hydrogels, specifically comprising the steps of:

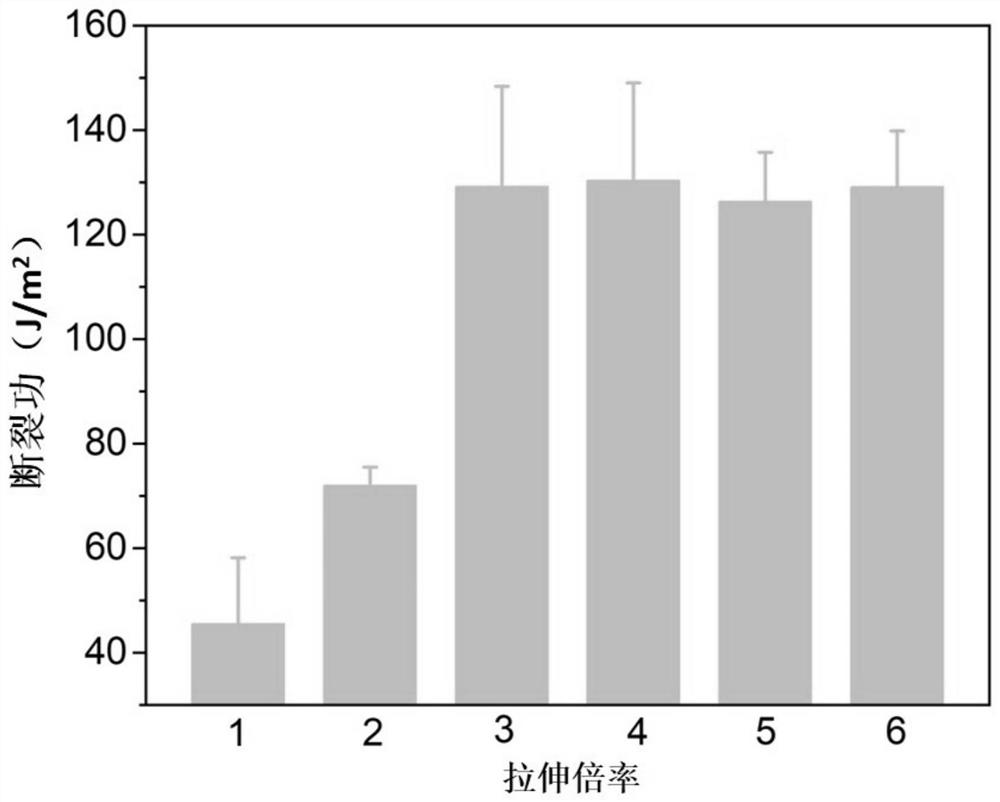

[0059] (1) The first hydrogel and the second hydrogel are respectively uniaxially stretched and fixed, and the stretching ratio of the uniaxial stretching is 3, and the stretched first hydrogel and the stretched first hydrogel are obtained. Dihydrogel;

[0060] (2) The stretched first hydrogel obtained in step (1) and the stretched second hydrogel are attached to the two surfaces of the dried hydrogel tape (provided in Preparation Example 1) respectively, and dried The hydrogel tape absorbs water and swells, releases the stretched first hydrogel and the second hydrogel to restore the original shape, and obtains a hydrogel bonded body with an oriented wrinkled structure.

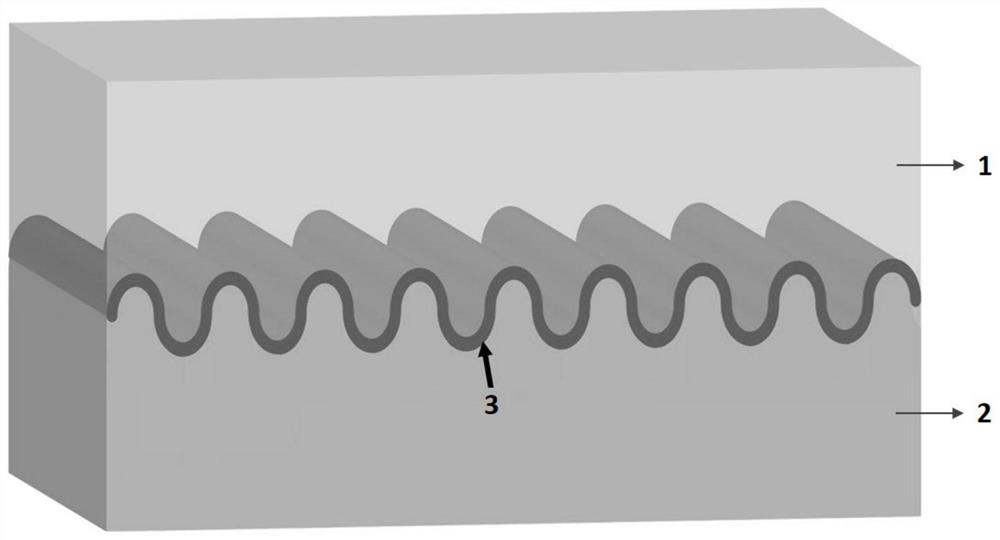

[0061] The schematic diagram of the structure of the hydrogel adhesive body with oriented wrinkled structure obtained in this example is as follows figure 1 Shown, among them, 1-the first hydrogel, 2-the second hydrogel, 3-orient...

Embodiment 2

[0066] A method for bonding hydrogels, the only difference from Example 1 is that the stretching ratios of the first hydrogel and the second hydrogel in step (1) are both 2; In the same manner as in Example 1, a hydrogel bonded body having an oriented wrinkled structure was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com