Light-resistant modified PP material and preparation method thereof

A light resistance and modification technology, applied in the field of PP materials, can solve the problems of poor light aging resistance and limited application, achieve the effects of inhibiting the photooxidation process, simple preparation method, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

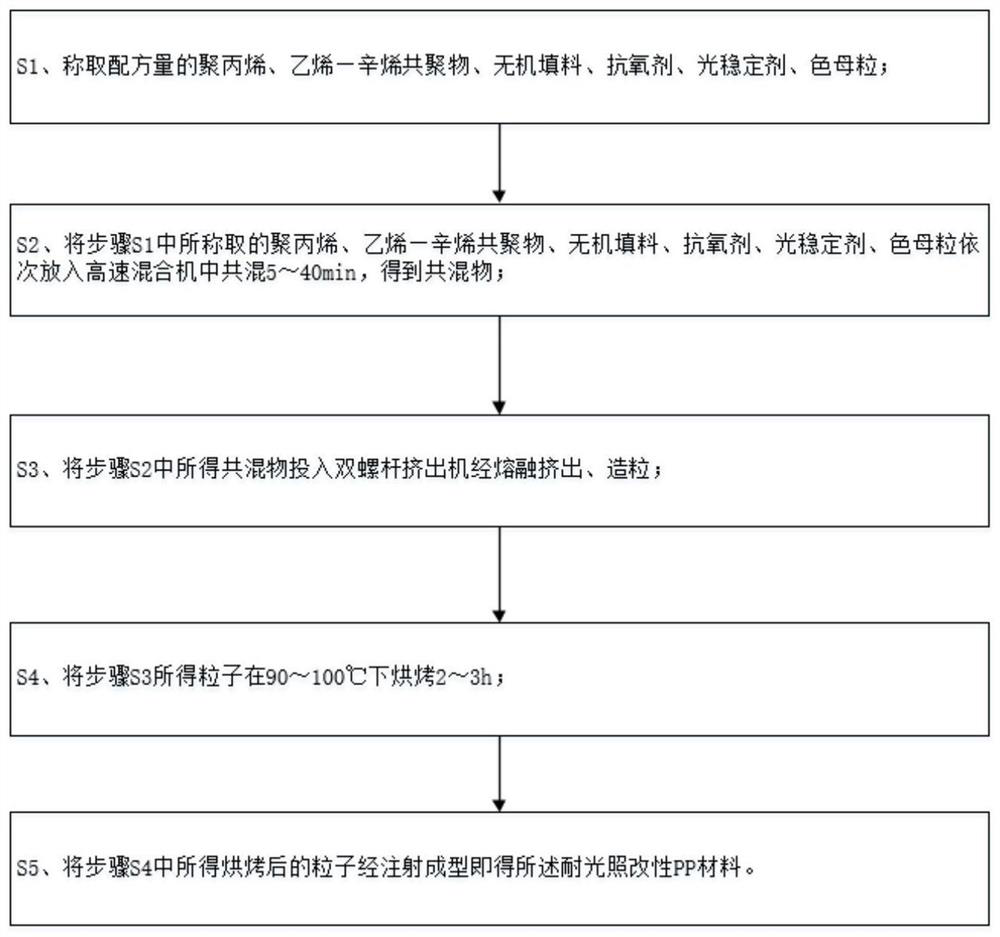

Method used

Image

Examples

Embodiment 1

[0028] A light-resistant modified PP material, comprising the following raw materials by weight: 65g of polypropylene, 5g of ethylene-octene copolymer, 5g of inorganic filler, 0.1g of antioxidant, and 0.1g of light stabilizer.

[0029] Among them, the polypropylene in this example is homopolypropylene; the melt index of the polypropylene in this example is 10-38g / 10min at 230°C and 2.16kg, and the ethylene-octene copolymer is at 190°C and 2.16kg. The melt index under the condition of 2.16kg is 0.5-10g / 10min.

[0030] Wherein, the inorganic filler in this embodiment is talc powder; the mesh number of talc powder is 3250 mesh.

[0031] The antioxidant in this embodiment is composed of a main antioxidant and a secondary antioxidant, and the mass ratio of the primary antioxidant to the secondary antioxidant is 2:1; wherein, the primary antioxidant is Oxygen 3114, and the secondary antioxidant The oxygen agent is antioxidant 618.

[0032] The light stabilizer in this embodiment i...

Embodiment 2

[0042] A light-resistant modified PP material, including the following raw materials by weight: 85g of polypropylene, 20g of ethylene-octene copolymer, 20g of inorganic filler, 3g of antioxidant, 3g of light stabilizer, and 4g of color masterbatch.

[0043] Wherein, the polypropylene in this embodiment is a mixture of homopolypropylene and copolymerized polypropylene

[0044] The melt index of polypropylene in this embodiment is 10-38g / 10min at 230°C and 2.16kg, and the melt index of ethylene-octene copolymer at 190°C and 2.16kg is 0.5-10g / 10min.

[0045] Wherein, the inorganic filler in this embodiment is a mixture of talcum powder and mica. Among them, the mesh number of the talc powder is 3000-5000 mesh, and the particle size of the mica is 120 μm.

[0046] The antioxidant in this embodiment is composed of a main antioxidant and a secondary antioxidant, and the mass ratio of the primary antioxidant to the secondary antioxidant is 2:1;

[0047] Among them, the main antioxi...

Embodiment 3

[0058] A light-resistant modified PP material, including the following raw materials: 78g of polypropylene, 10g of ethylene-octene copolymer, 15g of inorganic filler, 2.1g of antioxidant, 1.4g of light stabilizer, and 3g of masterbatch.

[0059] Wherein, the polypropylene in this embodiment is a mixture of homopolypropylene and copolymerized polypropylene.

[0060] The melt index of polypropylene in this embodiment is 10-38g / 10min at 230°C and 2.16kg, and the melt index of ethylene-octene copolymer at 190°C and 2.16kg is 0.5-10g / 10min.

[0061] Wherein, the inorganic filler in this embodiment is talcum powder. The mesh number of talcum powder is 3000-5000 mesh.

[0062] The antioxidant in this embodiment is composed of a main antioxidant and a secondary antioxidant, and the mass ratio of the primary antioxidant to the secondary antioxidant is 2:1;

[0063] Among them, the primary antioxidant is a mixture of antioxidant 1010 and antioxidant DSTP; the secondary antioxidant is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com