Energy tower refrigerant regeneration system based on air energy recovery

An energy recovery and regeneration system technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high refrigerant temperature, reduced regeneration efficiency, waste of sensible heat, etc., to improve regeneration efficiency and improve energy utilization. , the effect of improving the utilization rate of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

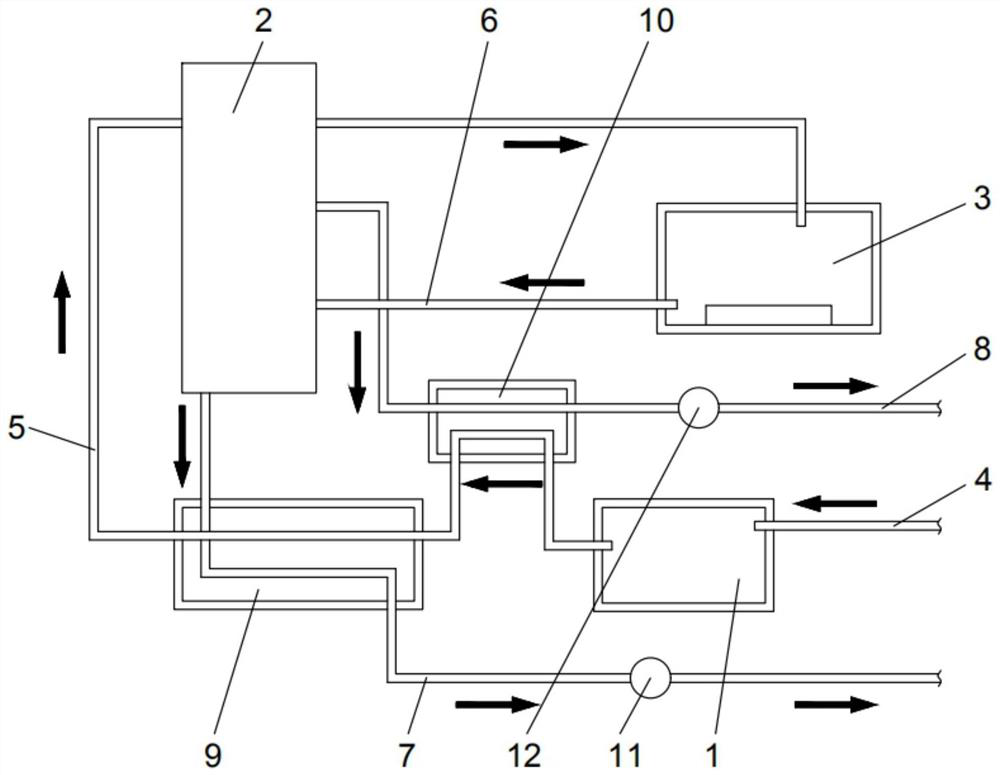

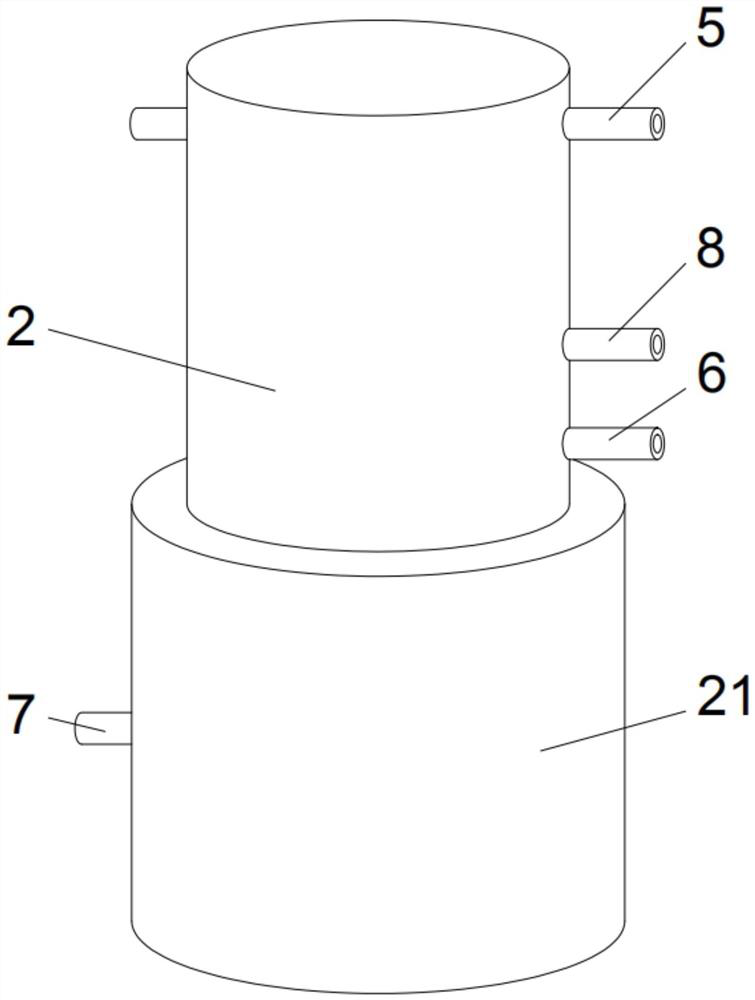

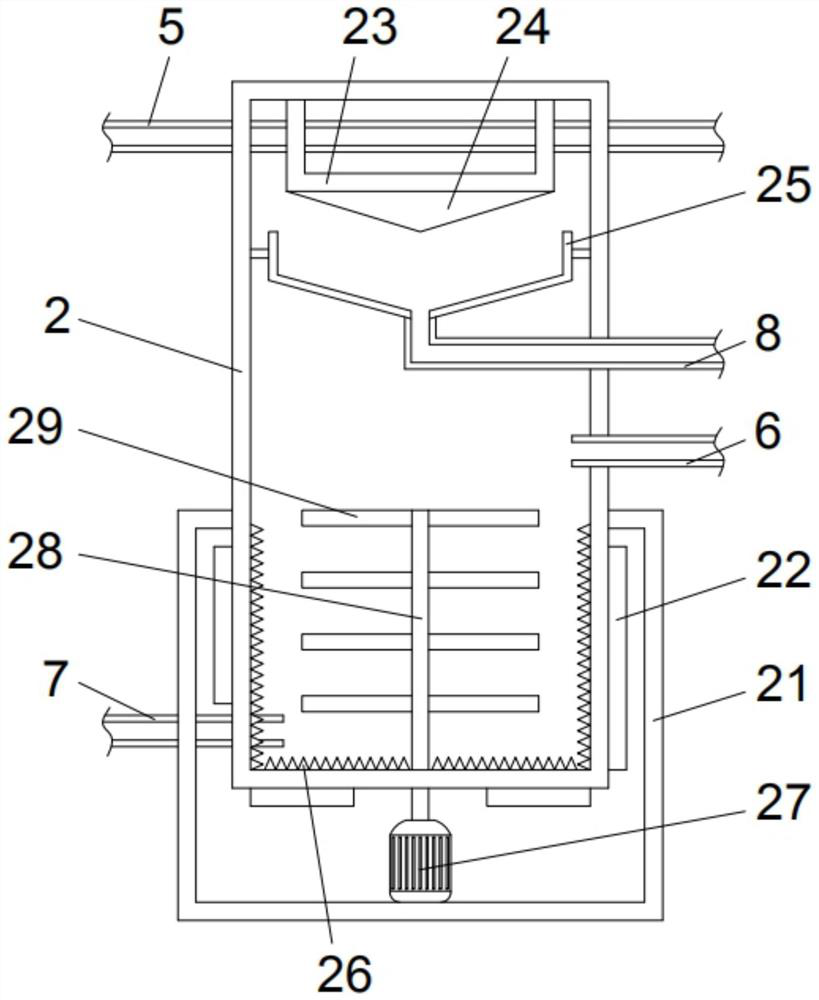

[0022]SeeFigure 1 ~ 3In the embodiment of the present invention, an energy tower cooling system based on air energy recovered, including a precipitation tank 1, a preheating assembly, an boiling evaporation tank 2, and an electric heater 3, and the input end of the precipitate tank 1 is fixedly connected The filling tube 4 of the injection solution is added to the sedimentation tank 1, and the output end of the precipitate tank 1 is fixedly connected to the first guidard tube 5, and the first guide tube 5 is fixedly mounted, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com