Preparation method of multi-layer coated probiotic microcapsule

A technology of microcapsules and probiotics, applied in the field of microorganisms, can solve the problems of porous surface, difficult to withstand high temperature and high pressure impact of feed pelleting, low survival rate of probiotics, etc., and achieve the effect of improving stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

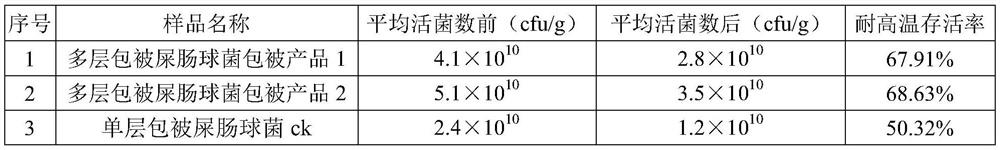

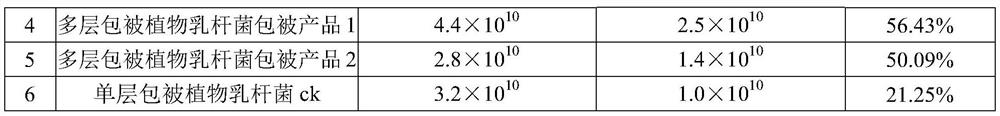

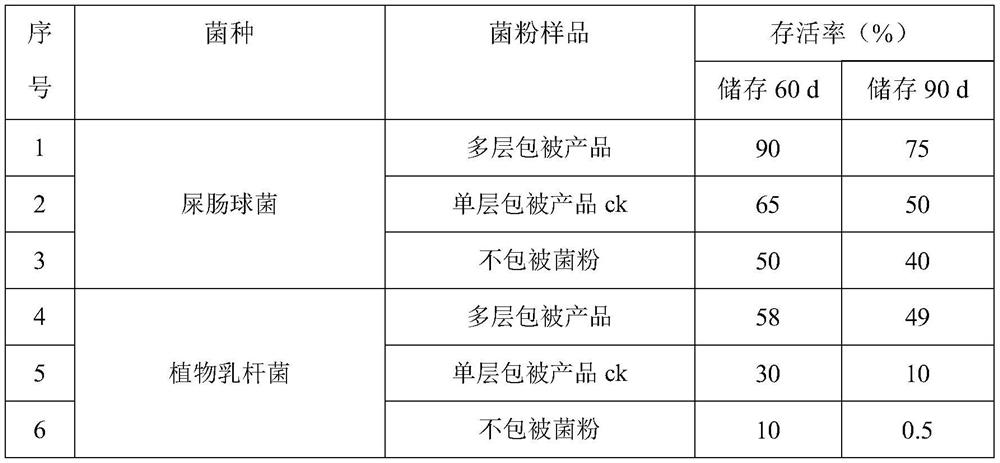

[0026] Embodiment 1: the preparation of multi-layer coated Enterococcus faecium microcapsule product

[0027] (1) preparing concentration is the sodium alginate solution of 10g / L in the feeding tank of fermentation system;

[0028] (2) Weigh calcium carbonate at a ratio of 1:1 to the sodium alginate mass ratio, add it to the feeding tank, mix evenly, sterilize, then cool to 37°C, add Enterococcus faecium at the end of logarithmic growth Seed liquid, to a probiotic density of 1 x 10 6 -5×10 6 cfu / ml, fully mixed as the water phase;

[0029] (3) Add Span 80 as the oil phase to the liquid paraffin, the volume percentage of the Span 80 is 0.1%, and add the oil phase to the fermenter for sterilization;

[0030] (4) prepare the calcium chloride solution of 0.1mol / L in another feeding tank as a settling agent, and sterilize;

[0031] (5) At a stirring speed of 400rpm, according to the ratio of the volume ratio of the water phase to the oil phase of 1:3, slowly transfer the water ...

Embodiment 2

[0036] Embodiment 2: the preparation method of multi-layer coated Lactobacillus plantarum microcapsule product

[0037] (1) preparation concentration is the sodium alginate solution of 20g / L in the feeding tank of fermentation system;

[0038] (2) Weigh calcium carbonate at a ratio of 1:5 to the sodium alginate mass ratio, add it to the feeding tank, mix evenly, sterilize, then cool to 37°C, add Lactobacillus plantarum at the end of logarithmic growth Seed liquid, to a probiotic density of 1 x 10 6 -5×10 6 cfu / ml, fully mixed as the water phase;

[0039] (3) Add Span 80 as the oil phase to the liquid paraffin, the volume percentage of the Span 80 is 0.3%, and the oil phase is added to the fermenter, and sterilized;

[0040] (4) prepare the calcium chloride solution of 0.3mol / L in another feeding tank as a settling agent, and sterilize;

[0041] (5) At a stirring speed of 500rpm, according to the ratio of the volume ratio of the water phase to the oil phase of 1:5, slowly tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com