Bromhexine hydrochloride freeze-dried powder injection for injection and preparation method of bromhexine hydrochloride freeze-dried powder injection

A technology of bromhexine hydrochloride and freeze-dried powder injection, which is applied in the field of bromhexine hydrochloride freeze-dried powder injection and its preparation, which can solve the problems of poor solubility and pain, and achieve reduced surface tension, increased solubility, and increased compliance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

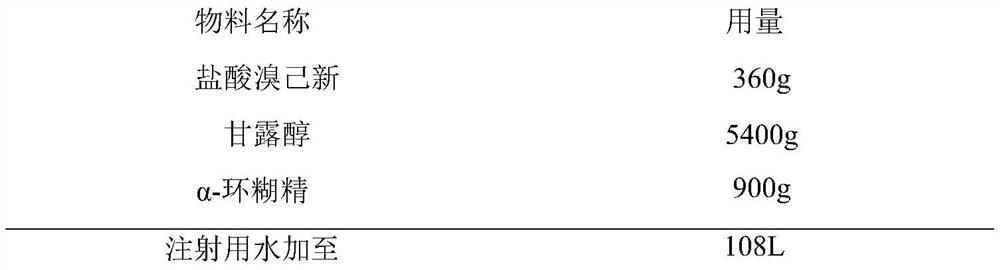

[0029] prescription:

[0030]

[0031] (1) Take bromhexine hydrochloride, add it to 20kg of ethanol at 60°C, and stir until completely dissolved. Take α-cyclodextrin and add 80kg of water, stir until completely dissolved;

[0032] (2) Add bromhexine hydrochloride ethanol solution into α-cyclodextrin aqueous solution, and stir for 3 hours.

[0033] (3) Add mannitol and citric acid buffer to adjust the pH to 6.0.

[0034] (4) Add water to make up to 108L, and stir evenly.

[0035] (5) Filter and fill with a 0.22 μm PES sterilizing filter.

[0036] (6) Freeze-drying: Based on the heat transfer oil outlet, keep warm for 2 hours below -40°C, then vacuumize; raise the temperature to 0°C, keep warm until the sublimation of free water is completed; heat up to the product temperature of 20-30°C, analyze again for 3 hours, freeze dry end.

Embodiment 2

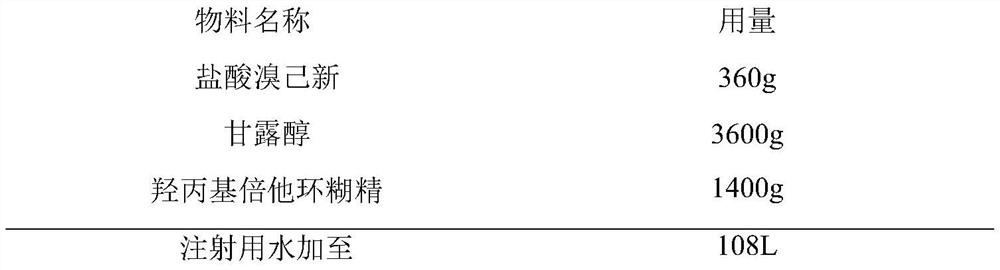

[0038] prescription:

[0039]

[0040] (1) Take bromhexine hydrochloride, add 50kg of hot water at 70°C, and stir until fully dissolved; add 50kg of water to hydroxypropyl beta-cyclodextrin, and stir until fully dissolved;

[0041] (2) Add bromhexine hydrochloride aqueous solution to hydroxypropyl beta cyclodextrin aqueous solution, and stir for 6 hours;

[0042] (3) Add mannitol and citric acid buffer to adjust the pH to 6.3;

[0043] (4) Add water to make the volume to 108L, and stir evenly;

[0044] (5) Filter and fill with a 0.22 μm PES sterilizing filter;

[0045] (6) Freeze-drying: Based on the heat transfer oil outlet, keep warm at -40°C for 2 hours, then vacuumize; heat up to 0°C, keep warm until the sublimation of free water ends; heat up to product temperature 20-30°C, analyze again for 4 hours, freeze dry end.

Embodiment 3

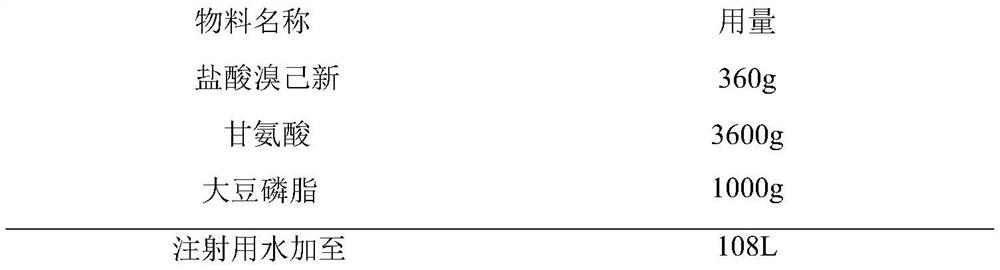

[0047] prescription:

[0048]

[0049] (1) Take bromhexine hydrochloride, add 10kg of hot ethanol at 60°C, and stir until fully dissolved; add 90kg of soybean lecithin, and stir until fully dissolved;

[0050] (2) adding bromhexine hydrochloride ethanol solution in soybean lecithin aqueous solution, colloid mill mixing 2 hours;

[0051] (3) adding glycine and phosphate buffer to adjust the pH value to 5.5;

[0052] (4) Add water to make the volume to 108L, and stir evenly;

[0053] (5) Filter and fill with a 0.22 μm PES sterilizing filter;

[0054] (6) Freeze-drying: Based on the heat conduction oil outlet, keep warm for 2 hours below -40°C, and then vacuumize; heat up to 5°C, keep warm until the sublimation of free water ends; heat up to product temperature 25-35°C, analyze again for 3 hours, freeze dry end;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com