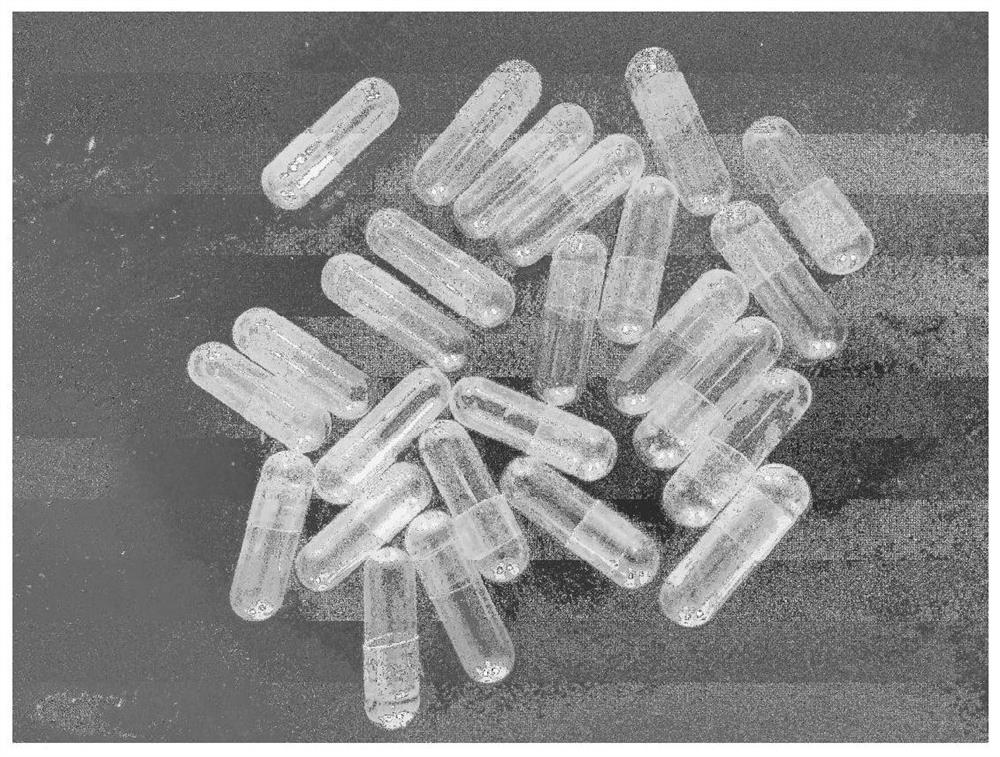

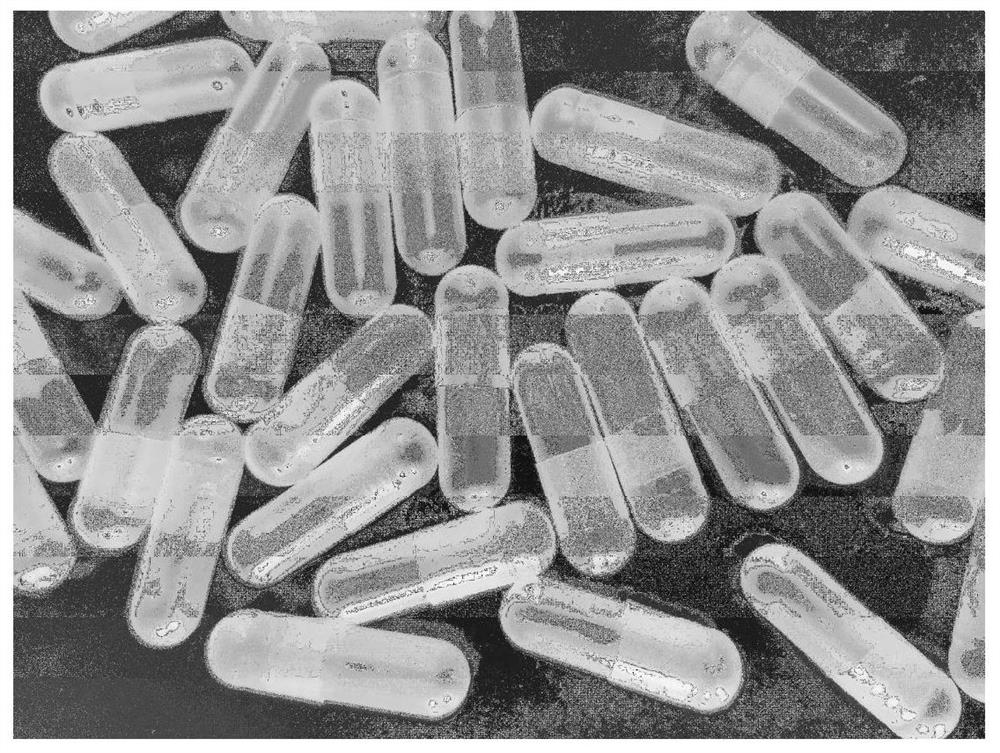

Enteric hollow cellulose capsule and preparation method thereof

A hollow capsule and cellulose technology, which is used in capsule delivery, pharmaceutical formulations, and medical preparations with inactive ingredients, etc., can solve problems such as no real solutions, and achieve good acid resistance stability, good mechanical properties, and good tolerance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

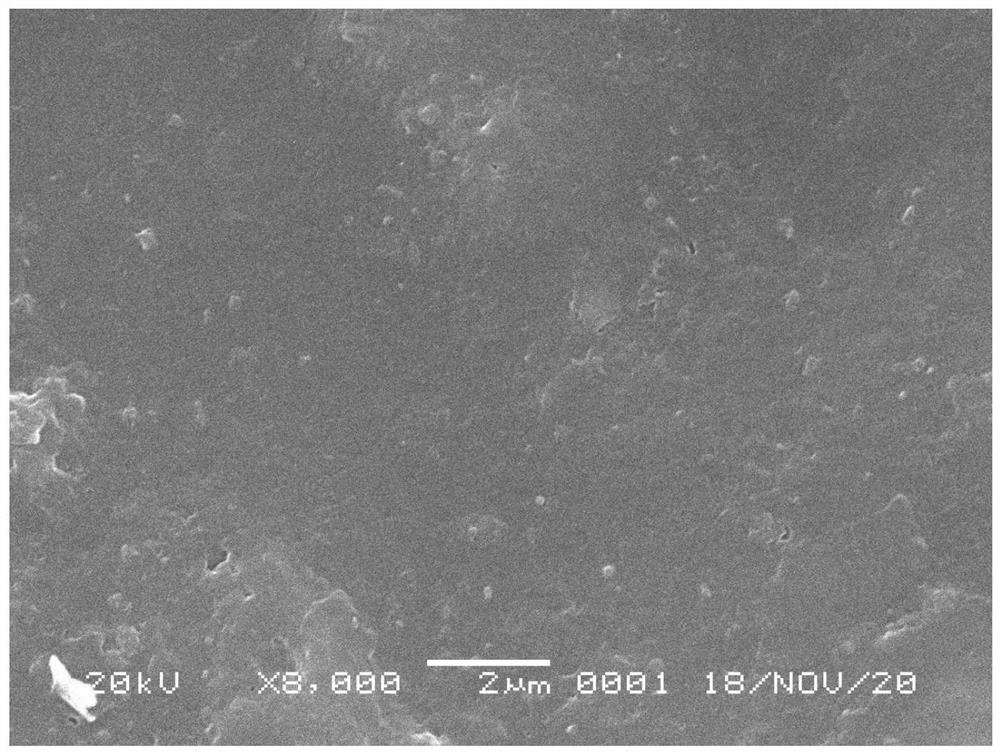

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] 1. The dissolution of hypromellose phthalate, the encapsulation material of enteric-coated hollow cellulose capsules, is the key to the preparation of enteric-coated hollow cellulose capsules. Weigh 16g of Hp55S and dissolve them in 100mL water containing different amounts of ammonia water, stir them well and place them aside to observe the effect of the amount of ammonia water on the solubility of Hp55S and the properties of glue. The results are shown in Table 1.

[0034] Table 1 The effect of the amount of ammonia water on the solubility and glue properties of Hp55S

[0035]

[0036] It can be seen from Table 1 that if the amount of ammonia water used is small to dissolve 16 g of Hp55S, the preparation of the glue solution will take a long time and the glue solution will turn white when the temperature rises to 50°C, indicating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com