Preparation method of battery-grade manganese dioxide

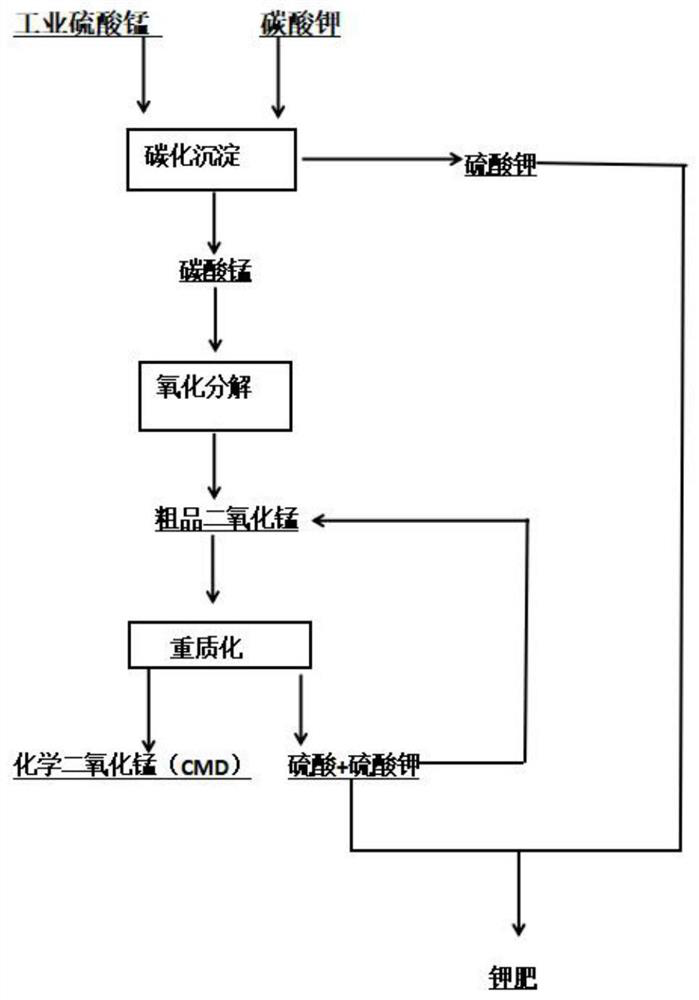

A manganese dioxide, battery-grade technology, used in manganese oxide/manganese hydroxide, battery electrodes, circuits, etc., can solve the problems of difficult waste liquid treatment, low efficiency, and outstanding environmental protection problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 130g of industrial manganese sulfate from a factory, dissolve it until the manganese content is 80g / L, take 500ml of manganese sulfate liquid, add it to the potassium carbonate solution with a mass fraction of 10%, control the feeding speed of manganese sulfate to 60ml / min, set the carbonization precipitation The temperature is 40°C, and the stirring rate is 300r / min. After the manganese sulfate liquid was added dropwise, the reaction was continued for 1 hour and then filtered, and the filter cake was taken and dried at 105°C. The dried manganese carbonate was placed in a muffle furnace, the temperature was set at 400° C., the oxygen flow rate was 0.1 L / min, and the thermal decomposition reaction was carried out for 6 hours to obtain crude manganese dioxide. Slurry the crude manganese dioxide according to the solid-to-liquid ratio of 1:2, add 50% sulfuric acid dropwise until the pH of the slurry remains at 1, then add a theoretical amount of potassium permanganate ...

Embodiment 2

[0029] Take 500g of an industrial manganese sulfate, dissolve it so that the manganese content is 90g / L, take 1500ml of manganese sulfate liquid, add it to the potassium carbonate solution with a mass fraction of 12%, control the feeding speed of manganese sulfate to 70ml / min, set the carbonization precipitation The temperature is 50° C., and the stirring rate is 350 r / min. After adding the materials, continue to react for 1 hour, then filter, take the filter cake, and dry it at 105°C. The dried manganese carbonate was placed in a muffle furnace, the temperature was set at 550° C., the oxygen flow rate was 0.1 L / min, and the thermal decomposition reaction was performed for 5 hours to obtain crude manganese dioxide. Slurry the crude manganese dioxide according to the solid-to-liquid ratio of 1:2, add 50% sulfuric acid dropwise until the pH of the slurry remains at 1, then add a theoretical amount of potassium permanganate according to the total manganese content of the liquid. ...

Embodiment 3

[0031] Take 1kg of an industrial manganese sulfate, dissolve it so that the manganese content is 100g / L, take 3000ml of manganese sulfate liquid, add it to the potassium carbonate solution with a mass fraction of 15%, control the feeding speed of manganese sulfate to 60ml / min, set the carbonization precipitation The temperature is 40° C., and the stirring rate is 300 r / min. After adding the materials, continue to react for 1 hour, then filter, take the filter cake, and dry it at 105°C. Place the dried manganese carbonate in a muffle furnace, set the temperature at 500° C., and set the oxygen flow rate at 0.15 L / min. Thermally decompose it for 4 hours to obtain crude manganese dioxide. The crude manganese dioxide is slurried according to the solid-to-liquid ratio of 1:2, and 50% sulfuric acid is added dropwise until the ph of the slurry remains at 1. Then, according to the total manganese content of the liquid, a theoretical amount of potassium permanganate is added. Stir and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com