Metallocene catalyst and preparation method and application thereof

A metallocene catalyst and reaction technology, applied in the field of metallocene catalysts, can solve the problem that the loading method of a novel restricted configuration double-bridged metallocene compound has not been reported, and achieves strong electron withdrawing, high loading rate and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

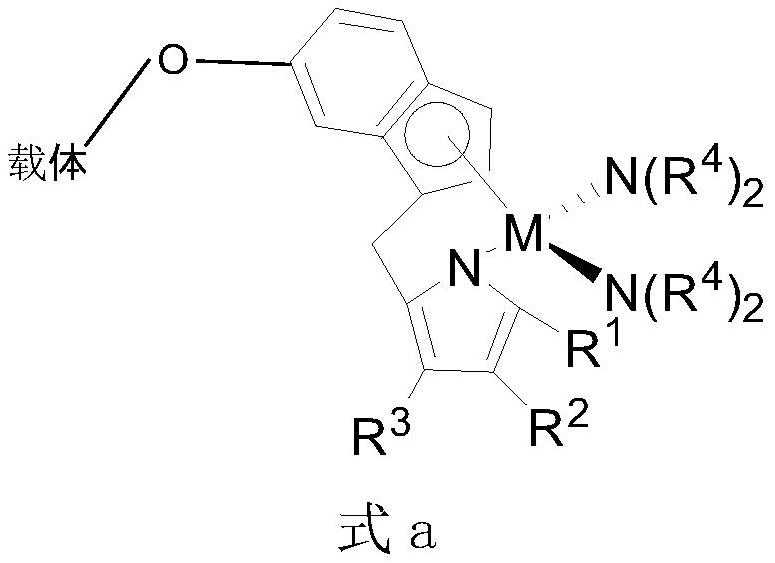

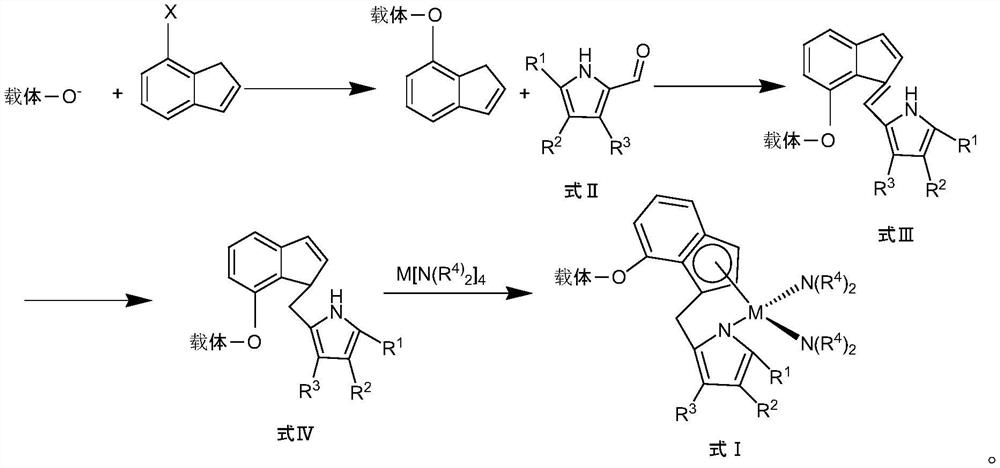

[0043] In addition, the present invention also provides a method for preparing a metallocene catalyst, comprising the steps of:

[0044] Step 1, reacting the halide of indene with the activated carrier to generate the carrier alcoholated indene;

[0045] Step 2, reacting the carrier alcoholized indene with formula II 2-pyrrole carboxaldehyde or its derivatives to prepare formula III nitrogen-containing fulvene, R 1 , R 2 and R 3 independently selected from H, CH 3 -, saturated or double bond containing straight or branched chain C 2 -C 10 One of the hydrocarbon groups;

[0046] Step 3, reducing the nitrogen-containing fulvene of formula III to generate a ligand of formula IV containing pyrrole N heterocycle; and

[0047] Step 4, the ligand of formula IV containing pyrrole N heterocycle and M[N(R 4 ) 2 ] 4 A complex reaction occurs to generate a metallocene catalyst of formula Ⅰ, R 4 C is a straight or branched chain 1 -C 5 alkyl;

[0048]

[0049] In detail, st...

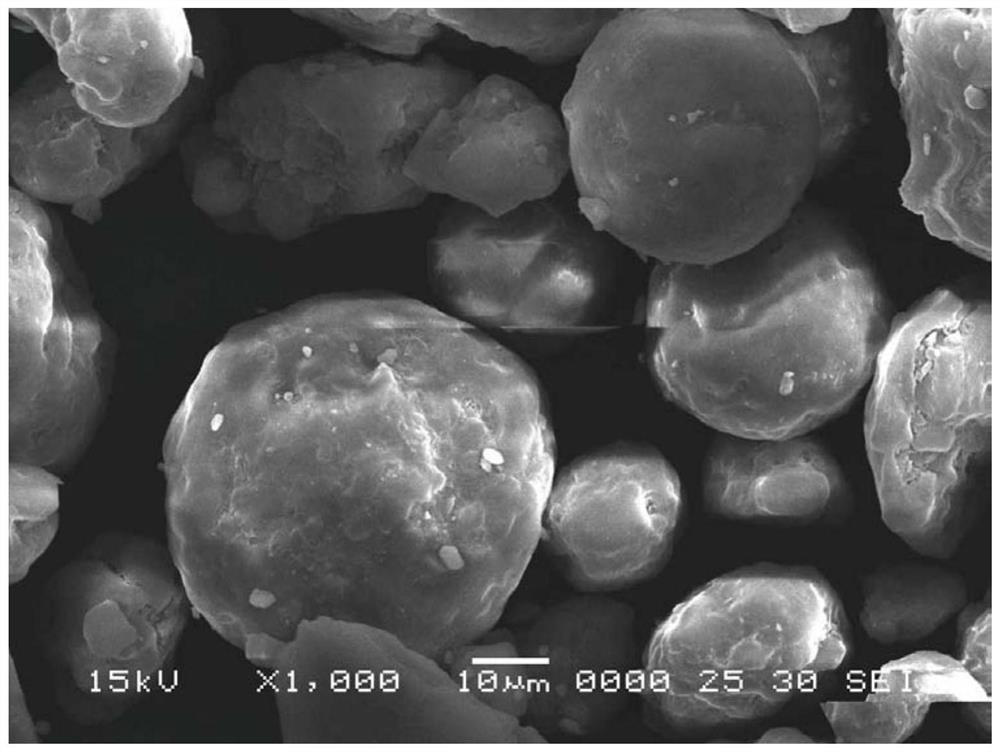

Embodiment 1

[0061] A synthetic supported metallocene catalyst, expressed as carrier-O-[(η 5 -C 9 h 6 )CH 2 (2-(3-CH 3 -4-CH 3 -C 4 HN))]Zr(NMe 2 ) 2 , wherein the inorganic carrier is silica, the activation process is to dry the inorganic carrier at 185°C for 18 hours, then bake it in oxygen or air at 600°C for 16 hours, and then replace it with an inert gas and keep it at the firing temperature for 15 hours. Cool to room temperature.

[0062] Place the activated carrier and indene bromide in an alkaline solution, control the temperature of the mixture at 60°C, stir at a constant temperature for 32 hours, and filter to obtain the carrier indene alcohol solid; the mass ratio of the carrier to indene bromide is 1:0.2. 3-CH 3 -4-CH 3 -5-CHO-C 4 HN and the carrier alcoholized indene were placed in the organic solvent acetaldehyde, cooled to -2°C, tetrahydropyrrole, 3-CH 3 -4-CH 3 -C 4 The ratio of HN-CHO, indene alcoholate and tetrahydropyrrole is 1:1.1:1.1. Then rise to room t...

Embodiment 2

[0066] A synthetic supported metallocene catalyst, expressed as carrier-O-[(η 5 -C 9 h 6 )CH 2 (2-(3-CH 3 -C 4 h 2 N))]Zr(NEt 2 ) 2 , wherein the inorganic carrier is silica, the activation process is to dry the inorganic carrier at 100°C for 20 hours, then bake it in oxygen or air at 500°C for 20 hours, and then replace it with an inert gas and keep it at the firing temperature for 12 hours. Cool to room temperature.

[0067] Put the activated carrier and indene chloride in an alkaline solution, control the temperature of the mixture at 120°C, stir at a constant temperature for 25 hours, and filter to obtain the carrier alcoholated indene solid; the mass ratio of the carrier to indene chloride is 1:0.3. 3-CH 3 -C 4 h 2 N-CHO and the carrier indene alcoholate are placed in an organic solvent, cooled to -8°C, and tetrahydropyrrole, pyrrole formaldehyde or its derivatives, indene alcoholate and tetrahydropyrrole are added dropwise in a ratio of 1:1.3: 1.3. Then rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com