Organic light emission diode device and fabrication method thereof

An electroluminescent device and luminescent technology, which are applied in the manufacture of organic semiconductor devices, electric solid devices, semiconductor/solid state devices, etc., can solve the problems of low device life and low luminous efficiency of organic electroluminescent devices, and achieve strong absorption Electronic properties, high-efficiency injection, and the effect of improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

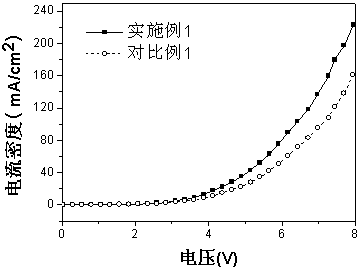

Embodiment 1

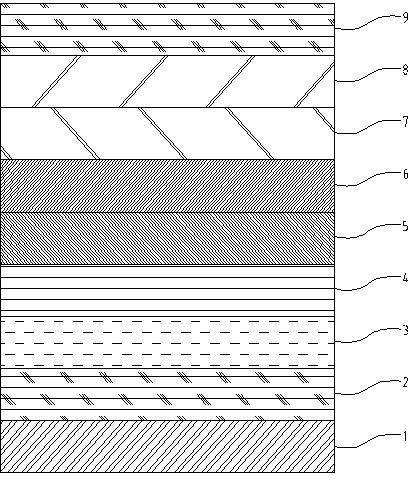

[0028] A method for preparing an organic electroluminescent device, comprising the following steps:

[0029] (1) A glass substrate is provided, and a conductive anode is prepared by vacuum sputtering on the surface of the glass substrate. The conductive anode is indium tin oxide (ITO), and a conductive anode is prepared by vacuum sputtering on the surface of the substrate 1, wherein,

[0030] The pressure when sputtering to prepare conductive anode is 1×10 -3 Pa, accelerating voltage 300V, power density 10W / cm 2 , The sputtering thickness is 70nm.

[0031] (2) The first hole injection auxiliary layer is vacuum evaporated on the surface of the conductive anode, and the material of the first hole injection auxiliary layer is molybdenum trioxide (MoO 3 ), the pressure when the first hole injection auxiliary layer is evaporated is 1×10 -3 Pa, the evaporation rate is 0.1nm / s, and the evaporation thickness is 0.5nm.

[0032] (3) The second hole injection auxiliary layer is vac...

Embodiment 2

[0043] A method for preparing an organic electroluminescent device, comprising the following steps:

[0044] (1) A glass substrate is provided, and a conductive anode is prepared by vacuum sputtering on the surface of the glass substrate. The conductive anode is made of indium zinc oxide (IZO), and a conductive anode is prepared by vacuum sputtering on the surface of the substrate. Among them,

[0045] The pressure when sputtering to prepare conductive anode is 1×10 -5 Pa, acceleration voltage is 800V, power density is 40W / cm 2 , the sputtering thickness is 200nm.

[0046] (2) The first hole injection auxiliary layer is vacuum evaporated on the surface of the conductive anode, and the material of the first hole injection auxiliary layer is vanadium pentoxide (V 2 o 5 ), the pressure when the first hole injection auxiliary layer is evaporated is 1×10 -5 Pa, the evaporation rate is 1nm / s, and the evaporation thickness is 5nm.

[0047] (3) The second hole injection auxiliary...

Embodiment 3

[0058] A method for preparing an organic electroluminescent device, comprising the following steps:

[0059] (1) A glass substrate is provided, and a conductive anode is prepared by vacuum sputtering on the surface of the glass substrate. The conductive anode is aluminum zinc oxide (AZO), and a conductive anode is prepared by vacuum sputtering on the surface of the substrate. Among them,

[0060] The pressure when sputtering to prepare conductive anode is 1×10 -4 Pa, accelerating voltage is 600V, power density is 20W / cm 2 , the sputtering thickness is 100nm.

[0061] (2) The first hole injection auxiliary layer is vacuum evaporated on the surface of the conductive anode, and the material of the first hole injection auxiliary layer is tungsten trioxide (WO 3 ), the pressure when the first hole injection auxiliary layer is evaporated is 1×10 -4 Pa, the evaporation rate is 0.1nm / s, and the evaporation thickness is 2nm.

[0062] (3) The second hole injection auxiliary layer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com