Multi-center supported catalyst as well as preparation method and application thereof

A supported catalyst, multi-center technology, applied in chemical instruments and methods, organic chemistry, titanium organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0149] The present invention also provides a preparation method for the above-mentioned supported multi-center composite catalyst, comprising the steps of:

[0150] Step 1, impregnating the carrier with a solution containing a vanadium source, drying and calcining;

[0151] Step 2, subjecting the carrier obtained in step 1 to dehydration and deoxidation activation treatment; and

[0152] Step 3, impregnating the activated support obtained in step 2 with a solution including an organic chromium source and a pyrrolene heterocyclic compound to obtain a multi-center supported catalyst;

[0153] Described organic chromium source comprises following structure:

[0154] R'-Cr-R

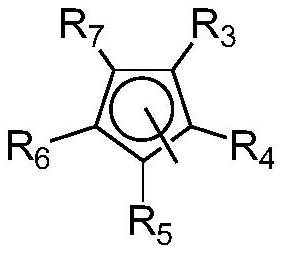

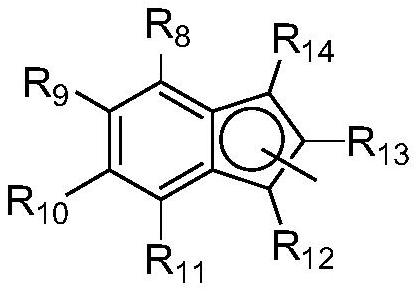

[0155] wherein R and R' are independently substituted or unsubstituted cyclopentadienyl, indenyl or fluorenyl;

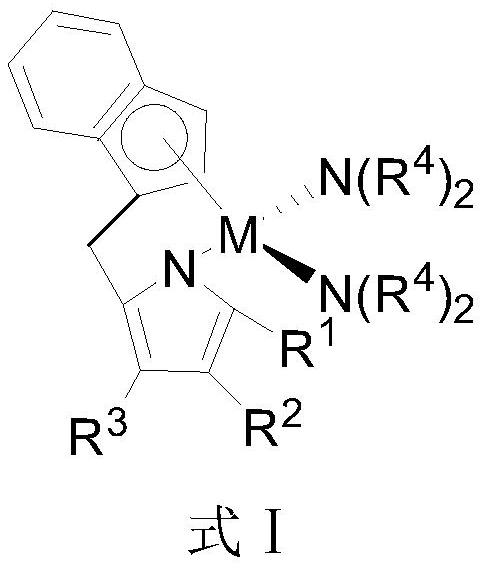

[0156] The pyrrolene heterocyclic compound has the following formula I structure:

[0157]

[0158] Among them, R 1 , R 2 and R 3 independently selected from H, CH 3 -, saturated or dou...

Embodiment 1

[0191] Inorganic carrier-supported multi-center composite catalyst, wherein the inorganic carrier is silica (the pore volume is 0.8cm 3 / g; the surface area of the inorganic carrier is 380m 2 / g); The inorganic vanadium source is vanadium nitrate, the organic chromium source is two (cyclopentadiene) chromium (II), and the pyrrolene heterocyclic compound is [(η 5 -C 9 h 6 )CH 2 (2-(3-CH 3 -4-CH 3 -5-CH 3 -C 4 N))]Zr(NMe 2 ) 2 .

[0192] The preparation method of pyrrololene heterocyclic compound is: the 3-CH 3 -4-CH 3 -5-CH 3 -2-Pyrrole formaldehyde and indene are cooled to -10°C, tetrahydropyrrole is added dropwise, the ratio of the three substances is 1:2:1, and then raised to room temperature and stirred for 10 hours to obtain nitrogen-containing fulvene; then cool down To -4°C, add lithium aluminum hydride dropwise, the molar ratio of nitrogen-containing fulvene to lithium aluminum hydride is 1:2, heat up to 70°C, stir and react for 10 hours to obtain a ligan...

Embodiment 2

[0195] Inorganic carrier-supported multi-center composite catalyst, wherein the inorganic carrier is silica (the pore volume is 1.3cm 3 / g; the surface area of the inorganic carrier is 590m 2 / g); The inorganic vanadium source is vanadium sulfate, the organic chromium source is two (ethylcyclopentadiene) chromium (II), and the pyrrolene heterocyclic compound is [(η 5 -C 9 h 6 )CH 2 (2-(3-CH 3 -4-CH 3 -C 4 HN))]Zr(NMe 2 ) 2 .

[0196] The preparation method of the pyrrololene heterocyclic compound is: the 3-CH 3 -4-CH 3 -2-Pyrrole formaldehyde and indene are cooled to -5°C, tetrahydropyrrole is added dropwise, the ratio of the three substances is 1:2:2, and then raised to room temperature and stirred for 5 hours to obtain nitrogen-containing fulvene; then cool down To -6°C, add lithium aluminum hydride dropwise, the molar ratio of nitrogen-containing fulvene to lithium aluminum hydride is 1:0.5, raise the temperature to 60°C, stir and react for 15 hours to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com