A three-dimensional ordered and controllable carbon fiber thermally conductive composite material and preparation method thereof

A thermally conductive composite material, three-dimensional ordered technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems that restrict the thermal conductivity of composite materials, unsatisfactory thermal conductivity, contact thermal resistance between fillers, and interface heat between fillers and substrates. In order to maintain the inherent performance, reduce the contact thermal resistance, and improve the interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

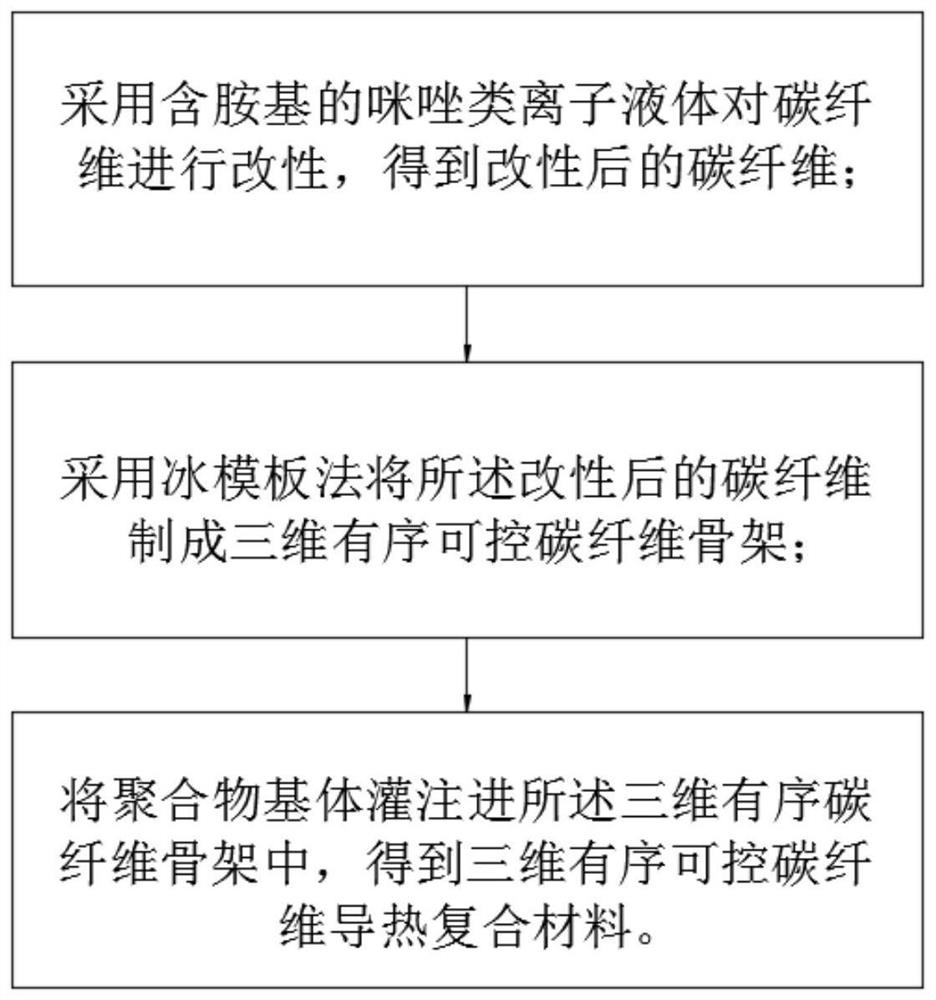

[0039] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a three-dimensional ordered and controllable carbon fiber thermally conductive composite material, including:

[0040] The carbon fiber is modified by imidazole ionic liquid containing amino groups to obtain the modified carbon fiber;

[0041] The modified carbon fiber is made into a three-dimensional ordered and controllable carbon fiber skeleton by ice template method;

[0042] The polymer matrix is poured into the three-dimensional ordered and controllable carbon fiber skeleton to obtain the three-dimensional ordered and controllable carbon fiber heat-conducting composite material.

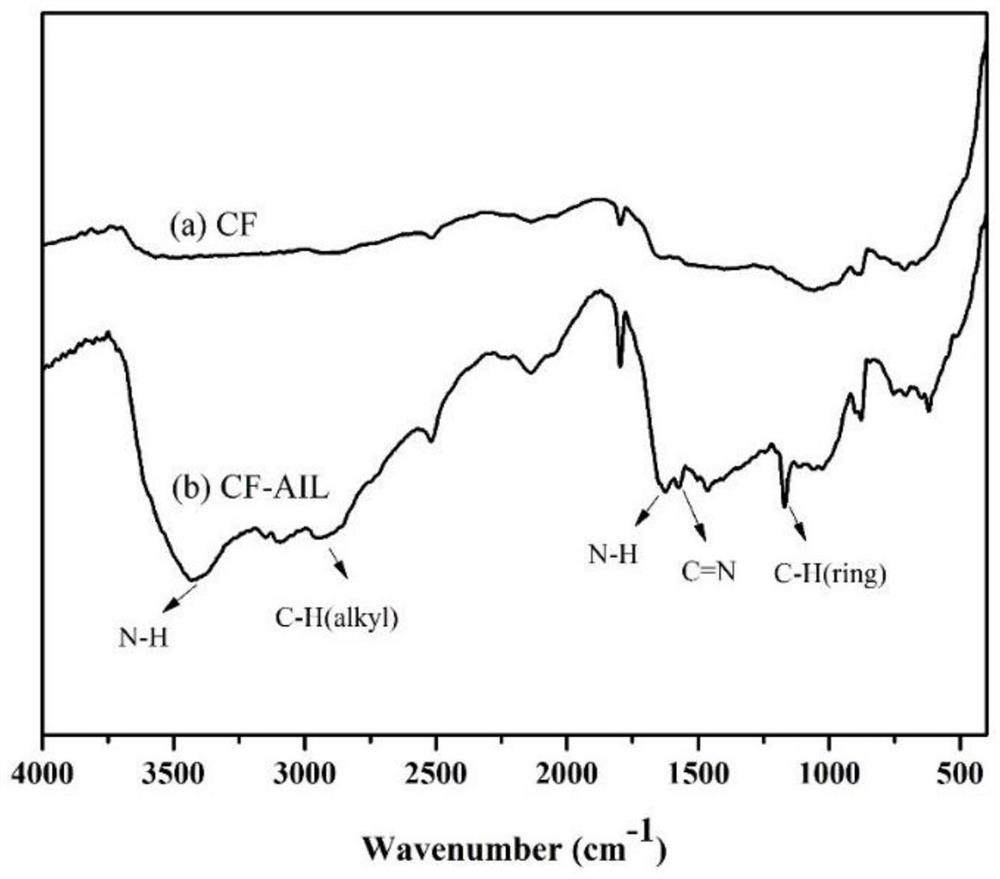

[0043] First, in this example, the imidazole-based ionic liquid containing amine groups can be attached to the surface of carbon fibers through cation-π interaction to perform non-covalent surface modification on carbon fibers.

[0044] Existing carbon fiber thermally conductive composi...

Embodiment 1

[0062] Weigh 500mg of ionic liquid 1-aminopropyl-3-methylimidazolium hydrobromide and disperse it in 1000ml of dimethylformamide (DMF), ultrasonically treat it to obtain a uniform ionic liquid dispersion, add 500mg of carbon fiber to the ion Stir in the liquid dispersion for 12 hours at room temperature, wash twice with ethanol to remove excess ionic liquid after the reaction, and dry in vacuum to obtain modified carbon fibers.

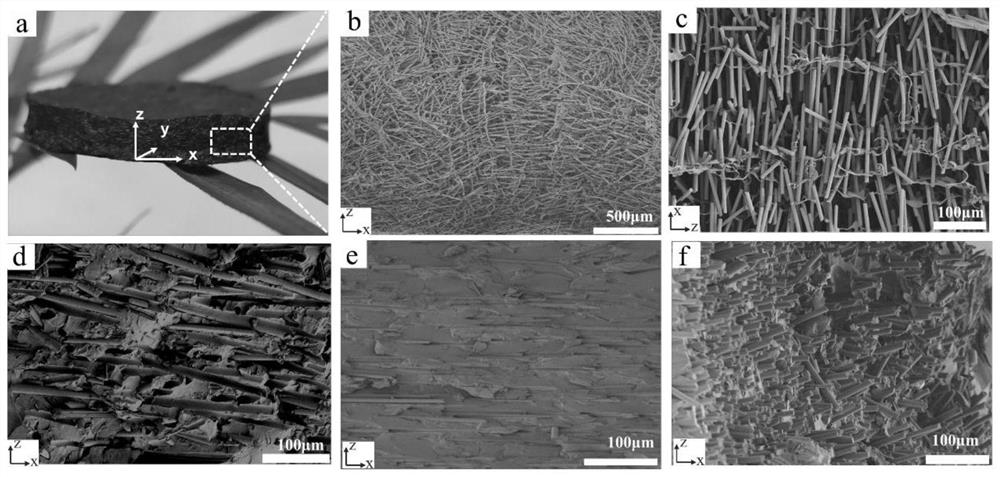

[0063] Surface-modified carbon fibers were freely dispersed in an aqueous solution containing hydroxyethyl cellulose (HEC) (1 wt%), stirred for 30 min to obtain a suspension, and the suspension was poured into a copper mold, and the mold was placed in liquid nitrogen After being vertically frozen for 12 hours, it was placed in a freeze dryer for 24 hours to freeze-dry to obtain a three-dimensional ordered and controllable carbon fiber skeleton.

[0064] Mix epoxy resin, catalyst (methylhexahydrophthalic anhydride), curing agent (2,4,6-(dimethylaminome...

Embodiment 2

[0072]Take 400mg of 1-aminopropyl-3-methylimidazolium hydrobromide and disperse it in 800ml of DMF, and obtain a uniform 1-aminopropyl-3-methylimidazolium hydrobromide dispersion by ultrasonic treatment, then add Add 400 mg of carbon fibers with a length of 350 μm into the dispersion, and stir at room temperature for 48 h. After the reaction, wash with ethanol twice to remove excess ionic liquid, and dry in vacuum to obtain modified carbon fibers.

[0073] Add 20 mg of hydroxyethyl cellulose to 2 ml of water, stir and dissolve in a water bath at 50° C., add the dried modified carbon fiber, and stir for 1 h to obtain a uniform suspension. The suspension was poured into a copper mold, and the mold was placed in liquid nitrogen for vertical freezing for 12 hours, and then placed in a freeze dryer for 24 hours to freeze-dry to obtain a three-dimensional ordered and controllable carbon fiber skeleton.

[0074] Mix 2ml of epoxy resin, 2ml of methylhexahydrophthalic anhydride, and 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com