Fireproof plugging module and preparation method thereof

A technology for fire blocking and moisture-proofing agent, which is applied in the field of fire blocking modules and their preparation, can solve the problems of poor weather resistance, inability to guarantee stable performance, and difficulty in playing a fireproof role, and achieves enhanced fire protection effects, The effect of protecting life and property safety and improving moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

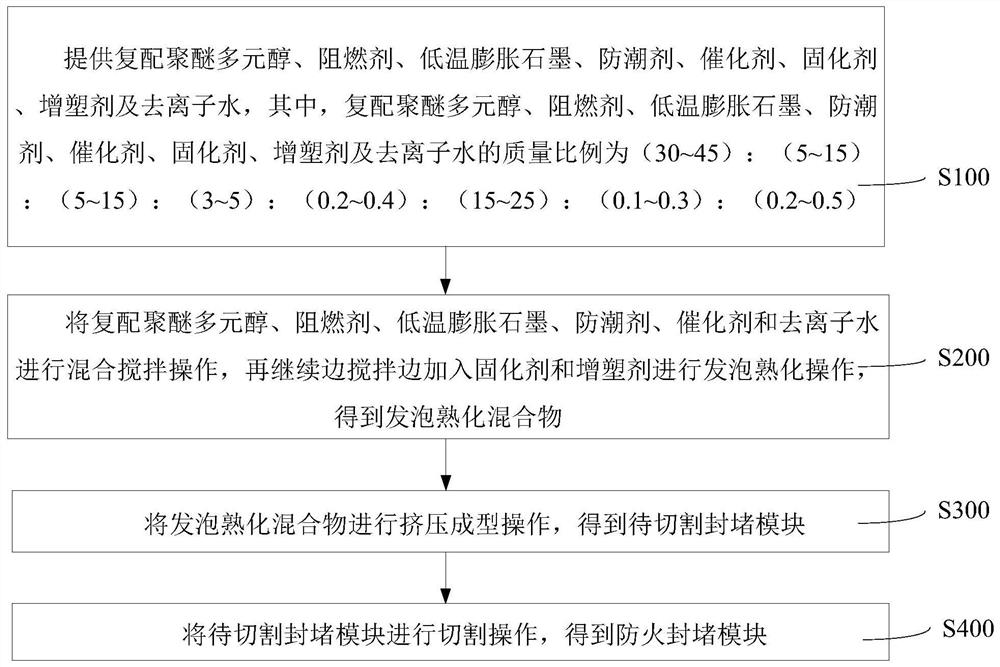

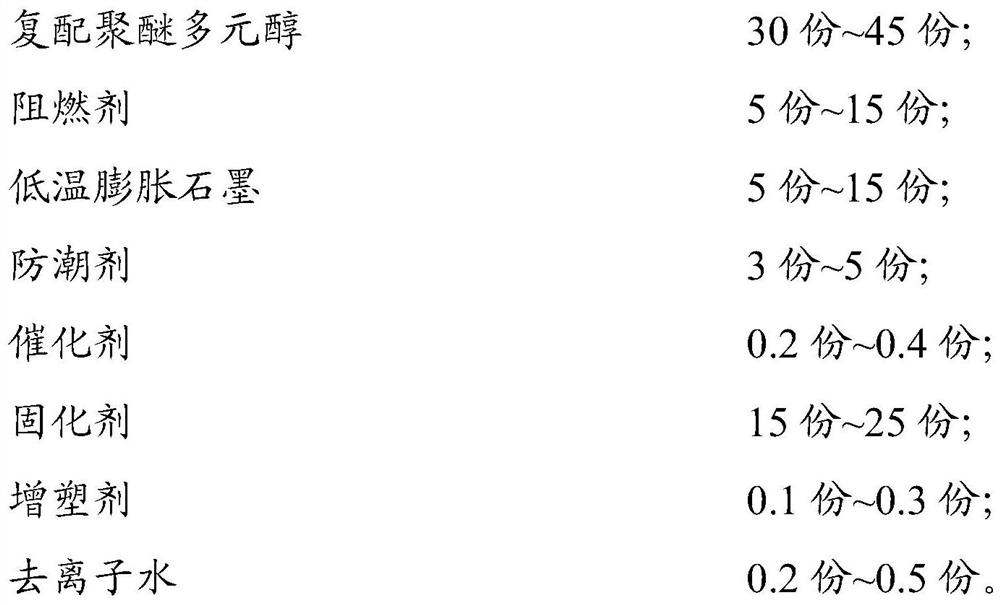

[0048] In order to better understand the fireproof sealing module of the present invention, the application also provides a preparation method of the fireproof sealing module, comprising the following steps: providing compounded polyether polyol, flame retardant, low-temperature expanded graphite, moisture-proof agent, catalyst , curing agent, plasticizer and deionized water, wherein, the compound polyether polyol, the flame retardant, the low-temperature expanded graphite, the moisture-proof agent, the catalyst, the curing agent, the The mass ratio of the plasticizer and the deionized water is (30-45): (5-15): (5-15): (3-5): (0.2-0.4): (15-25): (0.1~0.3): (0.2~0.5); the compound polyether polyol, the flame retardant, the low-temperature expanded graphite, the moisture-proof agent, the catalyst and the deionized water are mixed Stirring operation, and then continue to add the curing agent and the plasticizer while stirring to perform foaming and curing operations to obtain a f...

Embodiment 1

[0063] Provide 3kg compound polyether polyol, 0.5kg ammonium polyphosphate, 0.5kg low-temperature expanded graphite, 0.3kg dimethyl silicone oil, 0.02kg dimethylcyclohexylamine, 0.03kg ferrocene and 0.05kg iron oxide red. 3kg compound polyether polyol, 0.5kg ammonium polyphosphate, 0.5kg low-temperature expanded graphite, 0.3kg dimethyl silicone oil, 0.02kg dimethylcyclohexylamine, 0.03kg ferrocene and 0.05kg iron oxide red were added to the reaction In the still, adopt the stirring speed of 450 rev / min to carry out the mixing and stirring operation for 20 minutes, while continuing to stir, add 1.5kg aminoethylpiperazine and 0.01kg ethylene glycol to carry out the foaming and ripening operation for 25 minutes to obtain foaming Cook the mixture. Then put the foamed and matured mixture into a cold extrusion molding machine for extrusion molding operation to obtain the plugging module to be cut. The blockage module to be cut is cut in a pre-cutting manner to obtain a fireproof b...

Embodiment 2

[0065] Provide 4.5kg compound polyether polyol, 1.5kg ammonium polyphosphate, 1.5kg low-temperature expanded graphite, 0.5kg dimethyl silicone oil, 0.04kg dimethylcyclohexylamine, 0.05kg ferrocene and 0.1kg iron oxide red, Add 4.5kg compound polyether polyol, 1.5kg ammonium polyphosphate, 1.5kg low-temperature expanded graphite, 0.5kg dimethyl silicone oil, 0.04kg dimethylcyclohexylamine, 0.05kg ferrocene and 0.1kg iron oxide red In the reactor, adopt the stirring speed of 550 revs / min to carry out the mixing and stirring operation for 25 minutes, add 2.5kg aminoethylpiperazine and 0.03kg ethylene glycol and carry out the foaming ripening operation of 35 minutes while continuing to stir, obtain Foam-cured mixture. Then put the foamed and matured mixture into a cold extrusion molding machine for extrusion molding operation to obtain the plugging module to be cut. The blockage module to be cut is cut in a pre-cutting manner to obtain a fireproof blockage module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com