Natural flaky microwave absorbent and production process thereof

A technology of microwave absorber and production process, which is applied in other chemical processes, metal processing equipment, electrical components, etc., can solve the problems of narrow absorption band range, non-environmental protection in the production process, and large ferrite specificity, and achieve excellent microwave absorption Performance, low production cost, and variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

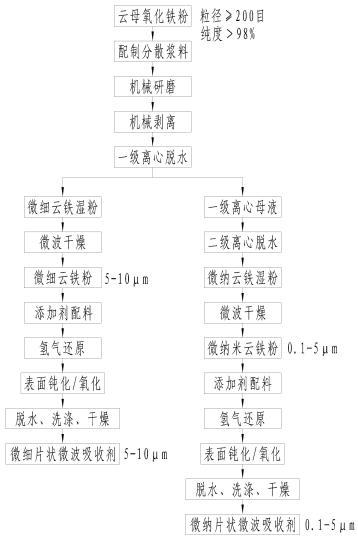

[0054] A kind of natural flaky microwave absorber and production technology thereof, comprises the following steps:

[0055] 1. Prepare dispersion slurry. Mica iron oxide powder with a particle size of 200 mesh or more and an iron oxide content of >98% is used as the main raw material, and water is added to prepare a suspension with a solid content of 27.5%, and then 2.75% of an aqueous dispersant is added to form a dispersion slurry.

[0056] 2. Mechanical grinding. Put the prepared dispersion slurry into a high-speed sand mill, and at the same time add zirconium beads with a particle size of 1.25 mm, and perform mechanical grinding at a speed of 4000 rpm for 35 minutes to obtain a mica iron oxide suspension with a particle size of less than 10 μm.

[0057] 3. Mechanical stripping. Dilute the micaceous iron oxide suspension obtained by the above-mentioned mechanical grinding with water to form a suspension with a solid content of 12.5%, then add it to a mechanical stripping...

Embodiment 2

[0075] A kind of natural flaky microwave absorber and production technology thereof, comprises the following steps:

[0076] 1. Prepare dispersion slurry. Mica iron oxide powder with a particle size of 200 mesh or more and an iron oxide content of >98% is used as the main raw material, and water is added to prepare a suspension with a solid content of 5%, and then 0.5% of an aqueous dispersant is added to form a dispersion slurry.

[0077] 2. Mechanical grinding. Put the prepared dispersion slurry into a high-speed sand mill, and at the same time add zirconium beads with a particle size of 0.5 mm, and perform mechanical grinding at a speed of 2000 rpm for 60 minutes to obtain a mica iron oxide suspension with a particle size of less than 10 μm.

[0078] 3. Mechanical stripping. Dilute the micaceous iron oxide suspension obtained by the above mechanical grinding with water to form a suspension with a solid content of 5%, then add it to a mechanical stripping device, and perfo...

Embodiment 3

[0096] A kind of natural flaky microwave absorber and production technology thereof, comprises the following steps:

[0097] 1. Prepare dispersion slurry. Mica iron oxide powder with a particle size of 200 mesh or more and an iron oxide content > 98% is used as the main raw material, and water is added to prepare a suspension with a solid content of 50%, and then 5% of an aqueous dispersant is added to form a dispersion slurry.

[0098] 2. Mechanical grinding. Put the prepared dispersion slurry into a high-speed sand mill, and at the same time add zirconium beads with a particle size of 2 mm, and perform mechanical grinding at a speed of 6000 rpm for 10 minutes to obtain a mica iron oxide suspension with a particle size of <10 μm.

[0099] 3. Mechanical stripping. Dilute the micaceous iron oxide suspension obtained by the above mechanical grinding with water to form a suspension with a solid content of 20%, then add it to a mechanical stripping device, and perform mechanical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com