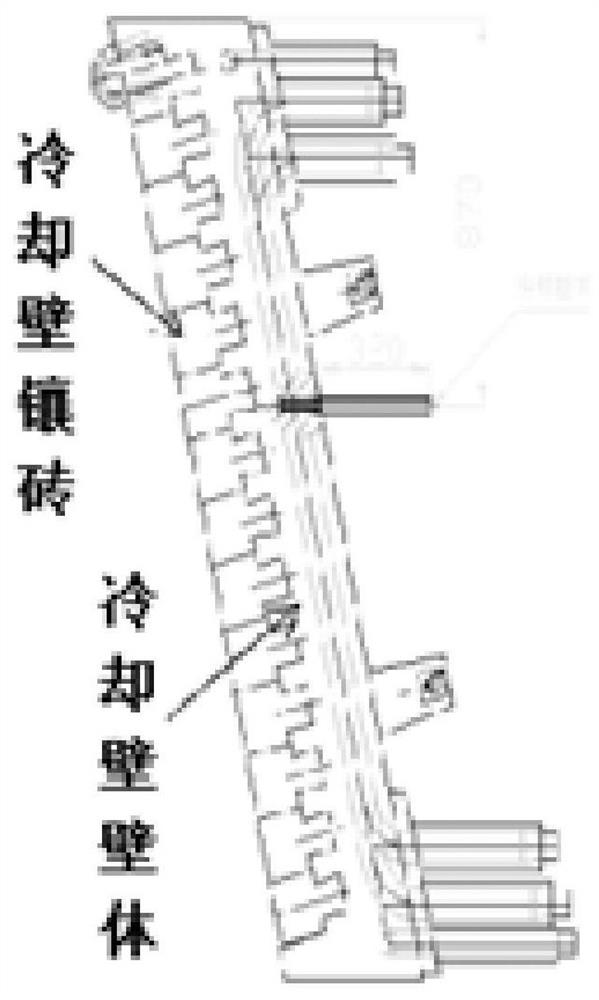

A brick-embedded stave structure resistant to thermal stress damage

A cooling stave and thermal stress technology, applied in cooling devices, furnaces, furnace types, etc., can solve the problems affecting the service life of the cooling stave, the longevity of the blast furnace, and the use time is not long, so as to improve the service life, low investment cost, The effect of eliminating thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The silicon nitride combined with silicon carbide bricks are used as refractory bricks, and the refractory mortar is made of silicon carbide. The main properties are shown in Table 1 and Table 2 below:

[0045] Table 1 Silicon nitride bonded silicon carbide bricks

[0046] project unit index SiC % ≥72 Si 2 N 4

% ≥21 Fe 2 O 3

% ≤0.7 Free Si % ≤0.4 Apparent porosity % ≤15 Bulk density g / cm 3

≥2.7 High temperature flexural strength (1400℃) MPa ≥50 Thermal conductivity (1200℃) W / m.k ≥16 Linear expansion rate (20~1000℃) % ≤4.8

[0047] Table 2 Silicon carbide refractory mortar

[0048]

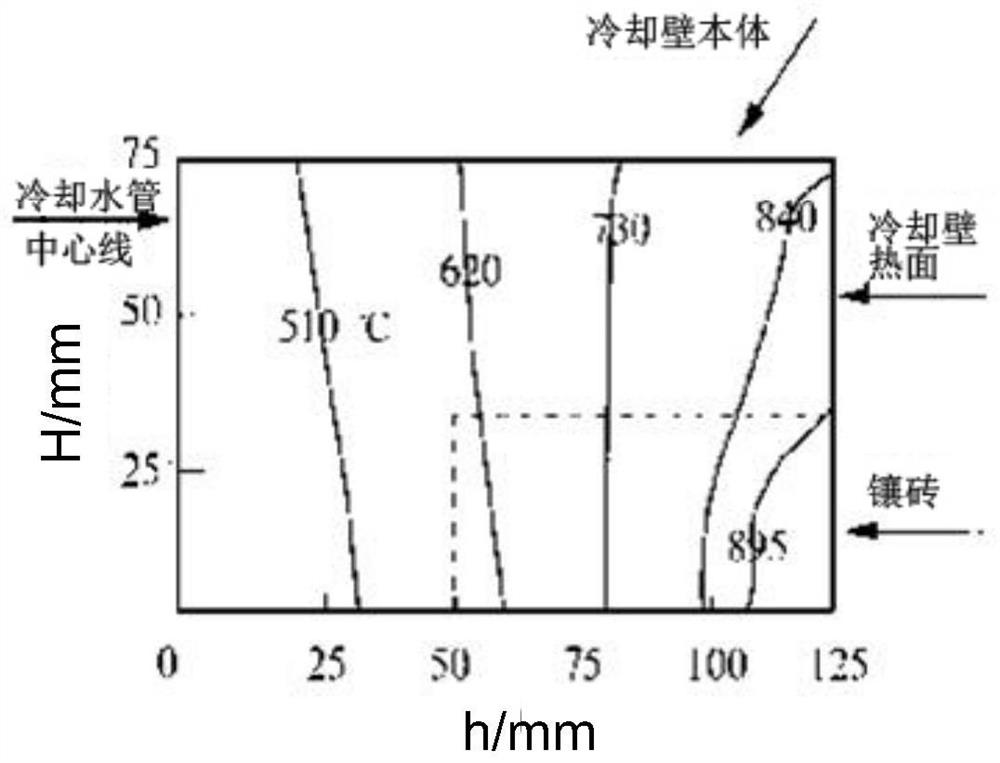

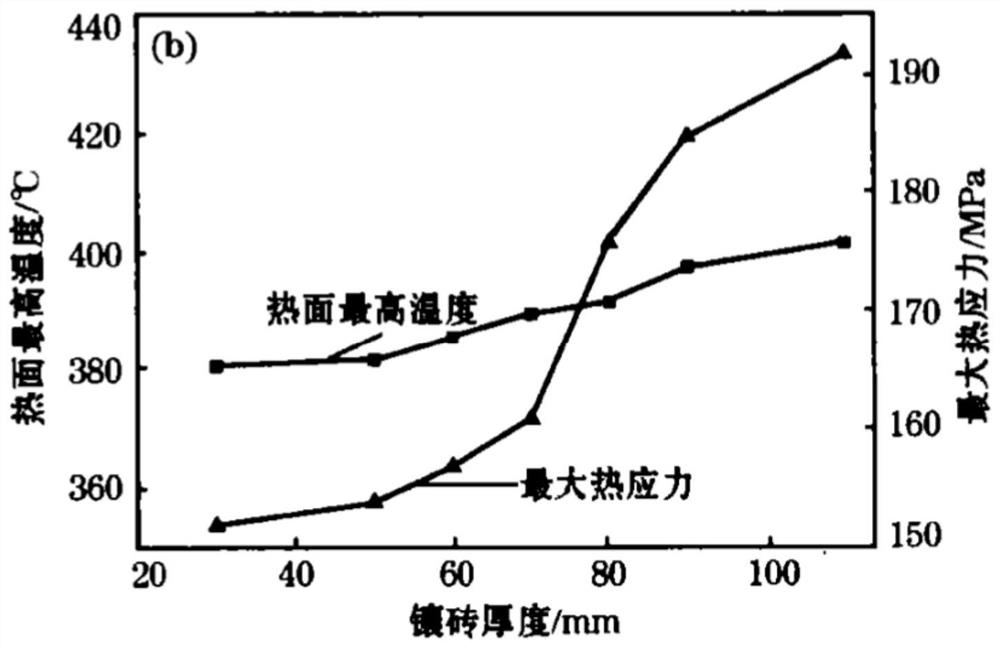

[0049] To sum up, the cooling wall inlaid brick structure of the present invention is to set a certain deformable space in the structure body. When the thermal stress reaches a certain level, the deformable space absorbs part of the strain amount to release the thermal stress, thereby alle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com