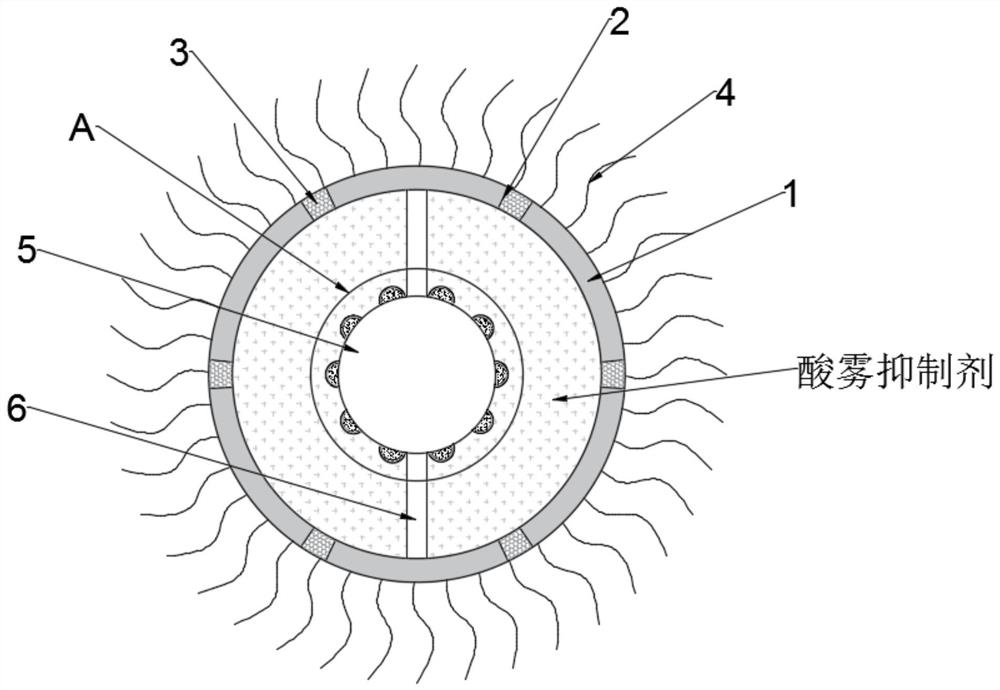

Acid mist inhibitor

An acid mist inhibitor and acid mist inhibition technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of affecting the acid mist inhibition effect, the acid mist fogging speed is fast, and the mist inhibition effect is not obvious. Excellent fog suppression effect, thick film thickness and high acid fog suppression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

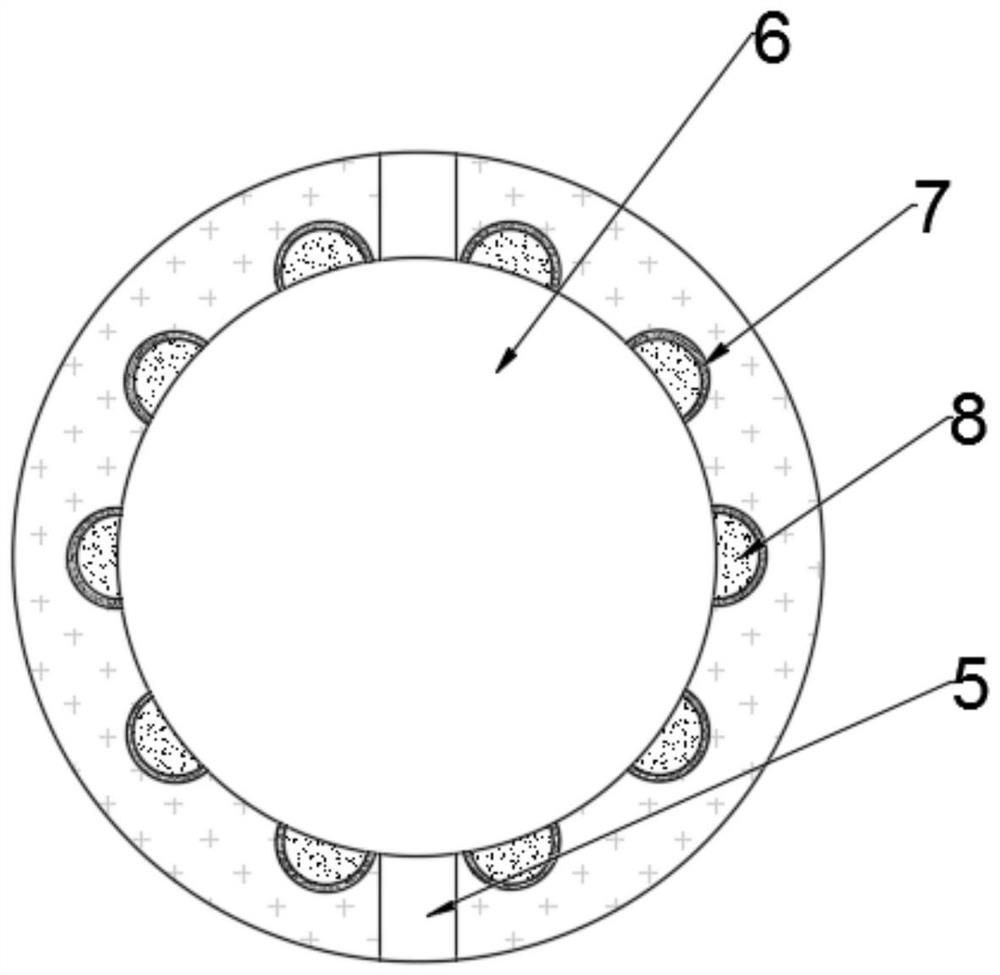

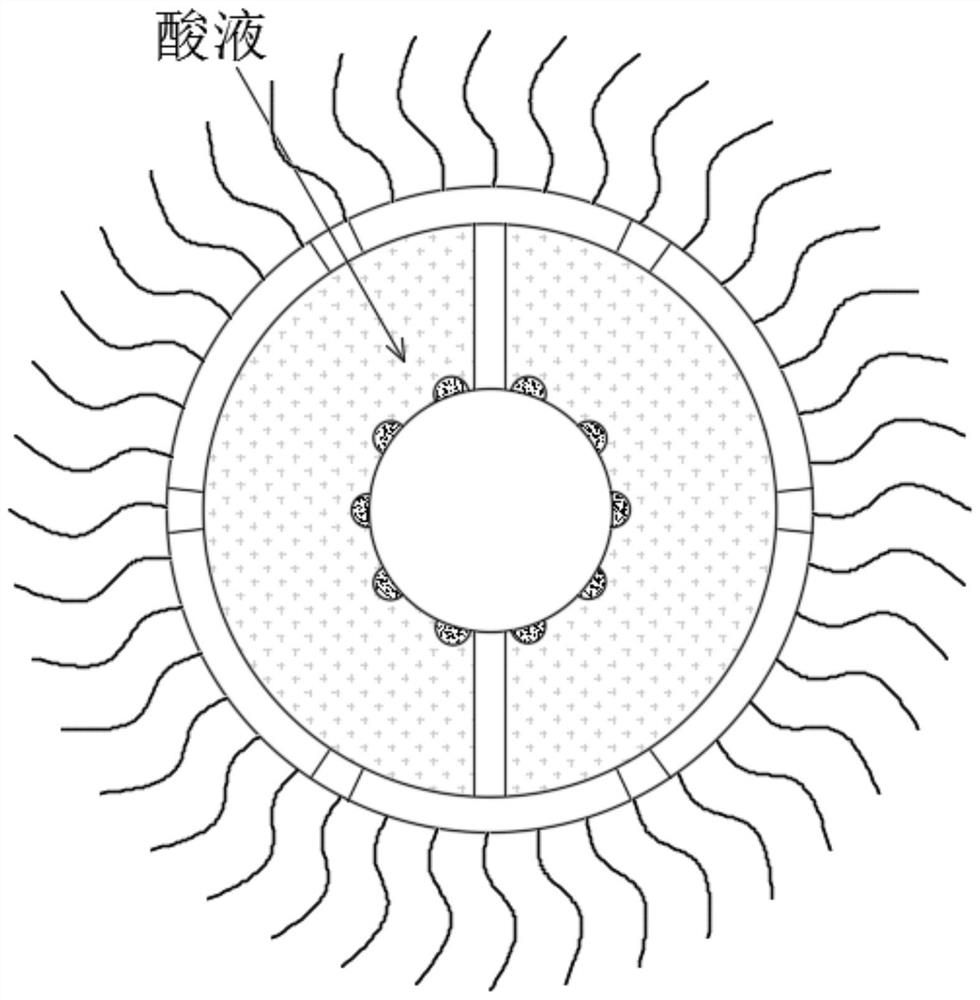

[0036] An acid mist suppressor, comprising an acid mist suppression ball and an acid mist suppressor, the acid mist suppressor is filled in the acid mist suppression ball, and the acid mist suppressor includes the following components by mass percentage: surfactant 5-10 %, molecular film-forming agent 5-10%, emulsifier 3-10%, foam stabilizer 0.5-1.5%, and the balance is solvent.

[0037] Among them, the surfactant is a mixture of anionic surfactant and nonionic surfactant, and the mass ratio of anionic surfactant and nonionic surfactant is 1-2:1, wherein the anionic surfactant is ten One of sodium dialkylbenzenesulfonate, sodium lauryl sulfate, and sodium lauryl sulfate. The nonionic surfactant is higher fatty alcohol polyoxyethylene ether, higher fatty acid polyoxyethylene ether, monostearic acid One of the glycerides.

[0038] The emulsifier is one or more mixtures of fatty alcohols, fatty acids, and fatty amines as hydrophobic base alkoxylates and their ester salts, alkyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com