Multi-component alloy diffusion couple device and multi-component alloy diffusion coefficient determination experiment method

A multi-element alloy and diffusion coefficient technology, applied in the field of experimental measurement of diffusion coefficient, can solve the problems of the difficulty of ensuring the neutrality of diffusion couples, the influence of diffusion coefficient measurement, and the error of measurement results. The effect of high device utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

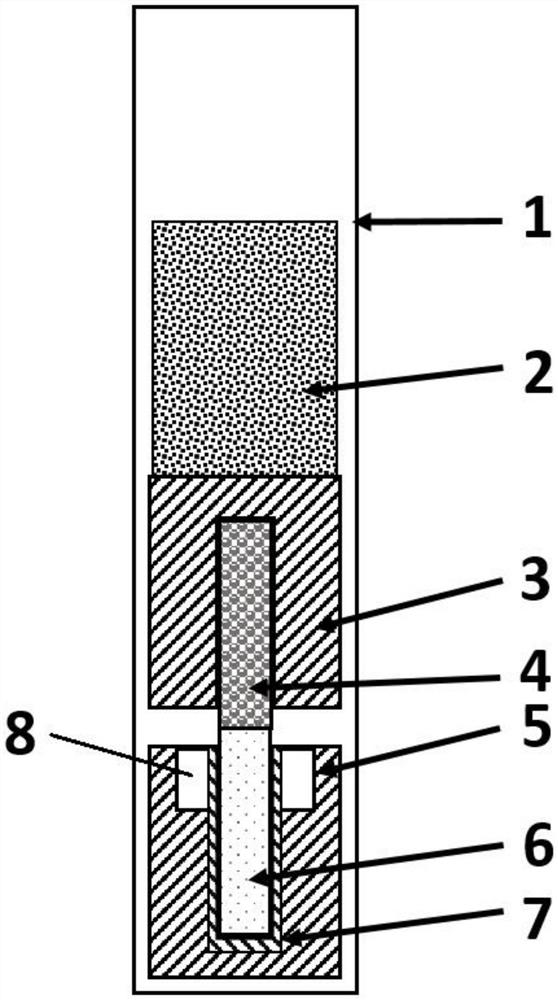

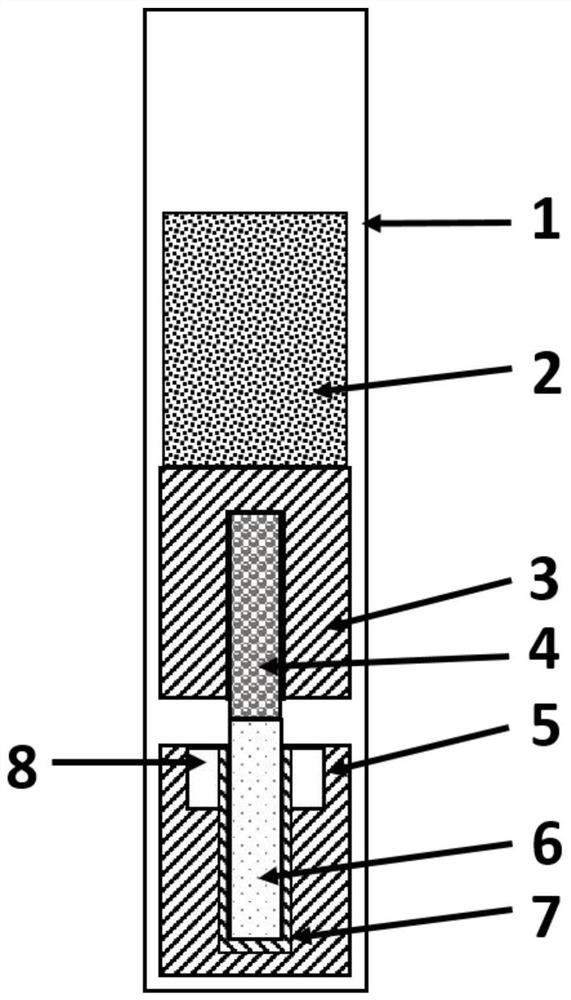

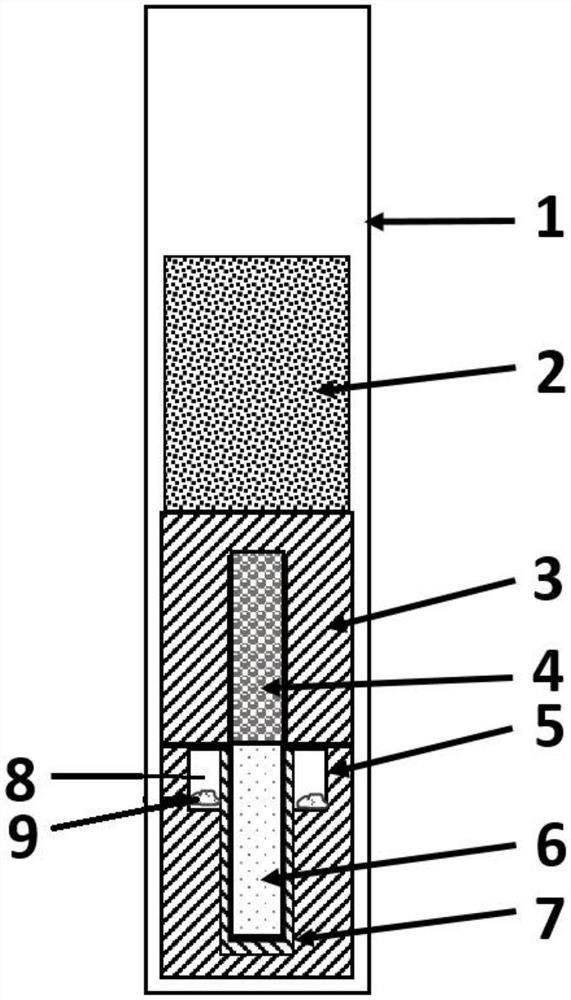

[0043] In this example, see figure 1 , a multi-component alloy diffusion couple device, including a first refractory material 3, a second refractory material 5, a third refractory material 7 and a weight module 2, the first refractory material 3, the second refractory material 5 and the third refractory material All materials 7 have blind holes;

[0044] The first refractory material 3 with a blind hole is used to accommodate the first metal solid material 4 for preparing the diffusion couple, assembled into an upper assembly, and the first metal solid material 4 exposed from the blind hole of the first refractory material 3 The end portion forms the lower interface of the first refractory material 3; the second refractory material 5 is provided with a stepped blind hole, and the stepped blind hole is composed of an upper reaming part and a lower receiving hole part, and the lower receiving hole part of the second refractory material 5 is used for The lower part of the third ...

Embodiment 2

[0049] This embodiment is basically the same as Embodiment 1, especially in that:

[0050] In this example, see figure 1 , the inner diameter of the quartz tube 1 is 5-50mm, and the height is 100-200mm;

[0051] The height of the counterweight module 2 is 30-50mm, and the diameter is 5-50mm; the material of the counterweight module 2 is stainless steel or other high melting point metal materials;

[0052] The height of the first refractory material 3 is 10-50 mm, the diameter is 5-50 mm, the height of the blind hole punched is at least 5 mm and not greater than 50 mm, and the diameter of the blind hole is 0.5-2 mm; in the center of the first refractory material 3 Blind holes are punched at the shaft position;

[0053] The height of the third refractory material 7 is 10-50mm, the diameter is 2-40mm, the height of the blind hole punched is at least 5mm and not greater than 50mm, and the diameter is 0.5-2mm; at the position of the central axis of the third refractory material 7...

Embodiment 3

[0059] This embodiment is basically the same as the previous embodiment, and the special features are:

[0060] In this example, see figure 1 Put the blind hole of the third refractory material 7 with the blind hole up into the blind hole of the second refractory material 5 to assemble the refractory material, so as to ensure the connection between the lower end of the third refractory material 7 and the second refractory material 5 The bottom of the blind hole is close, and the upper end of the third refractory material 7 is flush with the upper end surface of the upper reaming part of the second refractory material 5 .

[0061] The structure of each part of the device structure in this embodiment is appropriate. The upper end of the third refractory material 7 is flush with the upper end surface of the upper reaming part of the second refractory material 5, so that the edge end surfaces of the blind holes of each refractory material can be fully contacted. There will be no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com