Radio frequency SiP ceramic packaging shell and manufacturing method thereof

A technology of ceramic packaging and housing, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of increased RF signal transmission loss, increased manufacturing process steps, unfavorable RF SiP lightweight and miniaturization, etc. , to achieve the effect of improving the sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

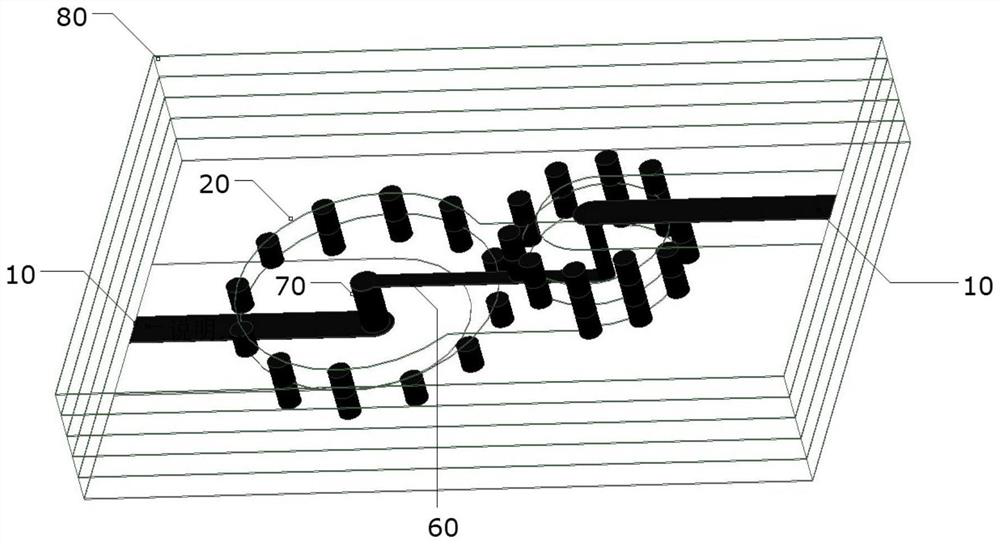

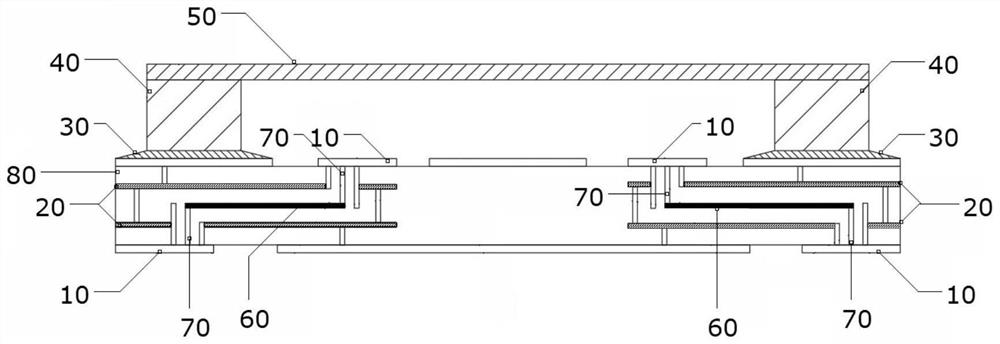

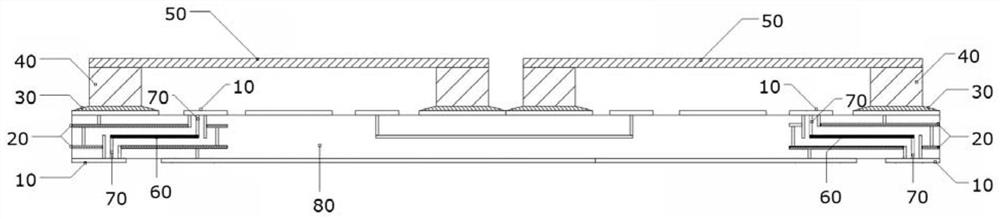

[0051] In this embodiment, the structure of the RF SiP ceramic package shell is as follows figure 2 As shown, its specific production method is as follows:

[0052] On the 8-layer LTCC green ceramic chip, according to the design pattern, each layer adopts thick film process screen printing to make interconnection vias, circuit wiring and electrical grounding patterns 20, specifically, on the third and seventh layer green ceramic chips Print the designed electrical grounding pattern 20, and the designed 4 quasi-coaxial transmission lines 70 are connected in pairs by two stripline transmission lines 60 printed on the fifth layer by screen;

[0053] Laminate 8 layers of LTCC green ceramic sheets with graphics printed on them according to the design sequence to form a substrate green body, heat and sinter at 850°C in the air for 10 minutes, then cool down to room temperature, and cut to form a package with an overall size of 9mm×9mm×0.8mm. The multilayer wiring ceramic substrate...

Embodiment 2

[0057] In this embodiment, the structure of the RF SiP ceramic package shell is as follows figure 2 As shown, its specific production method is as follows:

[0058] On the 12-layer aluminum nitride green ceramic sheet, each layer is printed and produced with interconnection holes, circuit wiring and electrical grounding patterns 20 according to the design pattern by using a thick film process. Print the designed electrical grounding pattern 20 on the 3rd layer and the 11th layer green ceramic sheet, and the designed 4 quasi-coaxial transmission lines 70 are connected in pairs by the 2 stripline transmission lines 60 printed on the 7th layer by screen;

[0059] Then, 12 layers of aluminum nitride green ceramic sheets with printed patterns were laminated according to the design sequence to form a substrate green body, which was heat-preserved and sintered at 1800°C for 4 hours in nitrogen, then cooled to room temperature, and cut into a shape of 20mm×20mm× A 1.8mm multilayer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com