Nickel-cobalt-aluminum ternary gradient positive electrode material precursor as well as yield production method and application thereof

A positive electrode material and production method technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems that the concentration gradient precursor cannot be produced industrially, and achieve the effect of ensuring consistency and avoiding aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

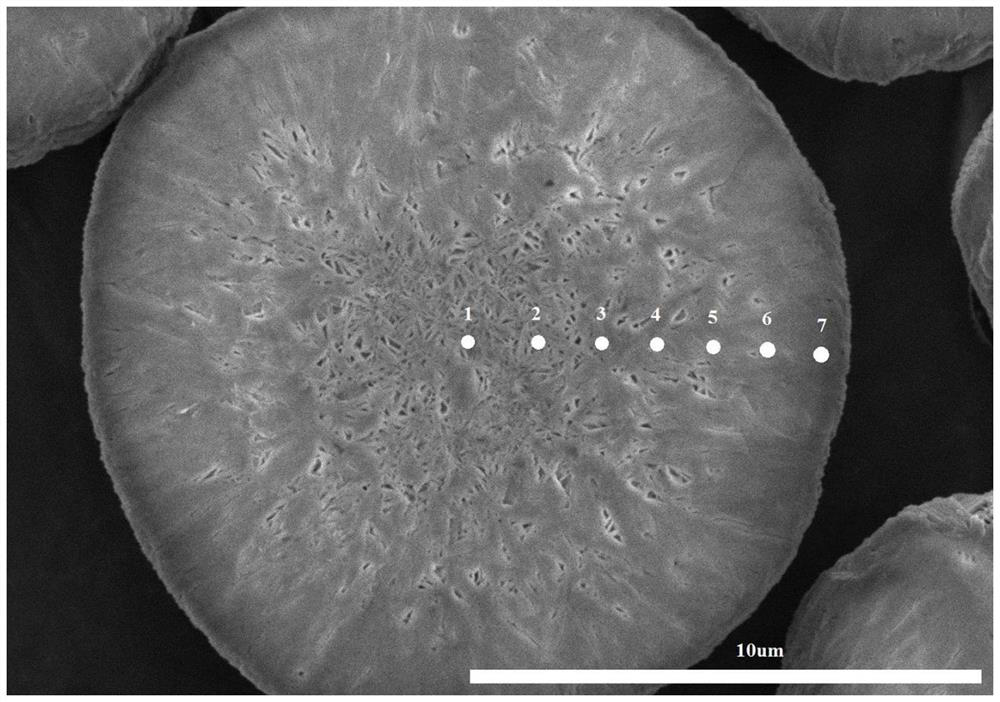

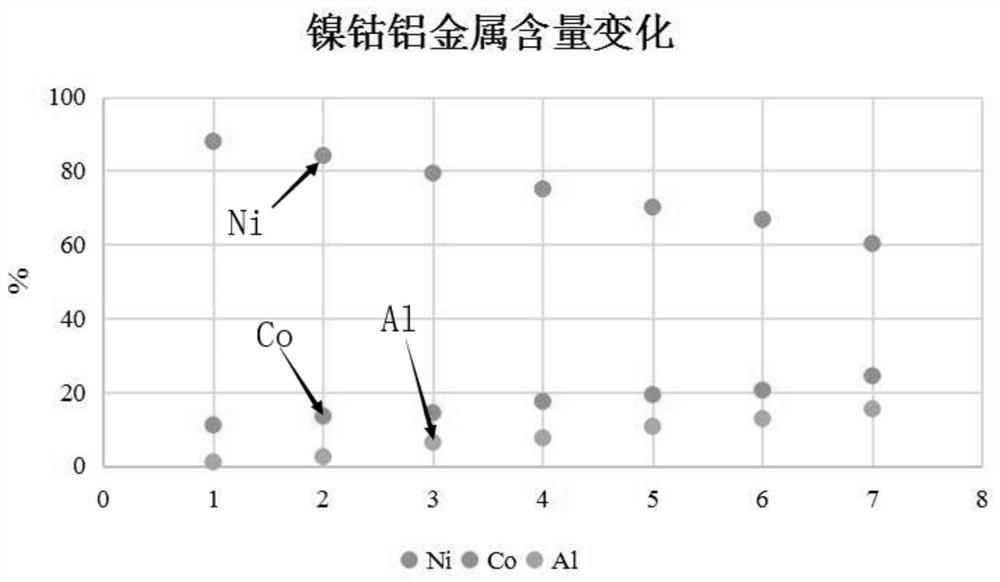

Image

Examples

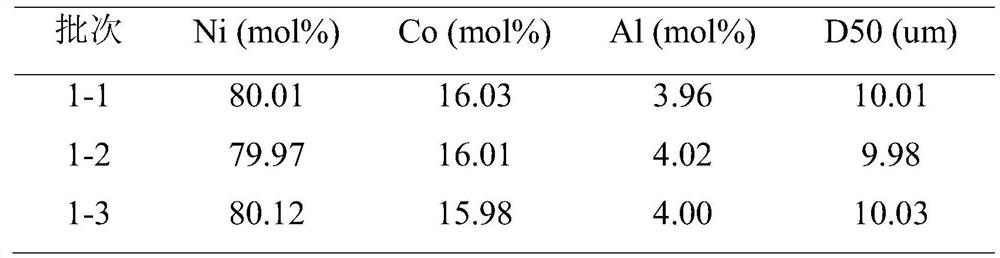

Embodiment 1

[0030] This embodiment provides a mass production method of a nickel-cobalt-aluminum ternary gradient positive electrode material precursor, the method includes the following steps:

[0031] S1, with nickel sulfate, the ratio of cobalt ammonium sulfate metal molar ratio is 93.3:16.7 and is mixed with the mixed solution that total metal concentration is 2mol / L;

[0032] Dissolve aluminum sulfate octadecahydrate in pure water, and add 32% industrial liquid caustic soda to prepare a sodium metaaluminate solution with an aluminum content of 0.5mol / L, wherein the volume ratio of pure water to 32% industrial liquid caustic is 8:1;

[0033] 32% industrial liquid caustic soda is used as the precipitating agent solution; 17% ammonia water is used as the complexing agent solution;

[0034] S2, add pure water in the reactor, usually the addition of pure water is no more than half of the solvent in the reactor, in the present embodiment it is at 10m 3 Add 5m to the reaction kettle 3 pu...

Embodiment 2

[0043] This embodiment provides a mass production method of a nickel-cobalt-aluminum ternary gradient positive electrode material precursor, the method includes the following steps:

[0044] S1, with nickel sulfate, the ratio that cobalt ammonium sulfate metal molar ratio is 89.8:10.2 is mixed with the mixed solution that total metal concentration is 2mol / L;

[0045]Dissolve aluminum sulfate octadecahydrate in pure water, and add 32% industrial liquid caustic soda to prepare a sodium metaaluminate solution with an aluminum content of 0.3mol / L, wherein the volume ratio of pure water to 32% industrial liquid caustic is 10:1;

[0046] 32% industrial liquid caustic soda is used as the precipitating agent solution; 17% ammonia water is used as the complexing agent solution;

[0047] S2, add pure water in the reactor, usually the addition of pure water is no more than half of the solvent in the reactor, in the present embodiment, it is at 8m 3 Add 4m to the reactor 3 Pure water o...

Embodiment 3

[0055] This embodiment provides a mass production method of a nickel-cobalt-aluminum ternary gradient positive electrode material precursor, the method includes the following steps:

[0056] S1, with nickel sulfate, the ratio that cobalt ammonium sulfate metal molar ratio is 96:4 is mixed with the mixed solution that total metal concentration is 2mol / L;

[0057] Dissolve aluminum sulfate octadecahydrate in pure water, and add 32% industrial liquid caustic soda to prepare a sodium metaaluminate solution with an aluminum content of 0.1mol / L, wherein the volume ratio of pure water to 32% industrial liquid caustic is 12:1;

[0058] 32% industrial liquid caustic soda is used as the precipitating agent solution; 17% ammonia water is used as the complexing agent solution;

[0059] S2, add pure water in the reaction kettle, usually the addition of pure water is no more than half of the reaction kettle solvent, in the present embodiment is at 6m 3 Add 3m to the reactor 3 pure water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com