Harmless treatment method and system for oily sludge

A technology for harmless treatment and sludge, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Achieve the effect of improving equipment utilization, reducing environmental pollution, and avoiding physical harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with examples. The following examples are only used to illustrate the present invention, and should not be regarded as limiting the scope of claims of the present invention.

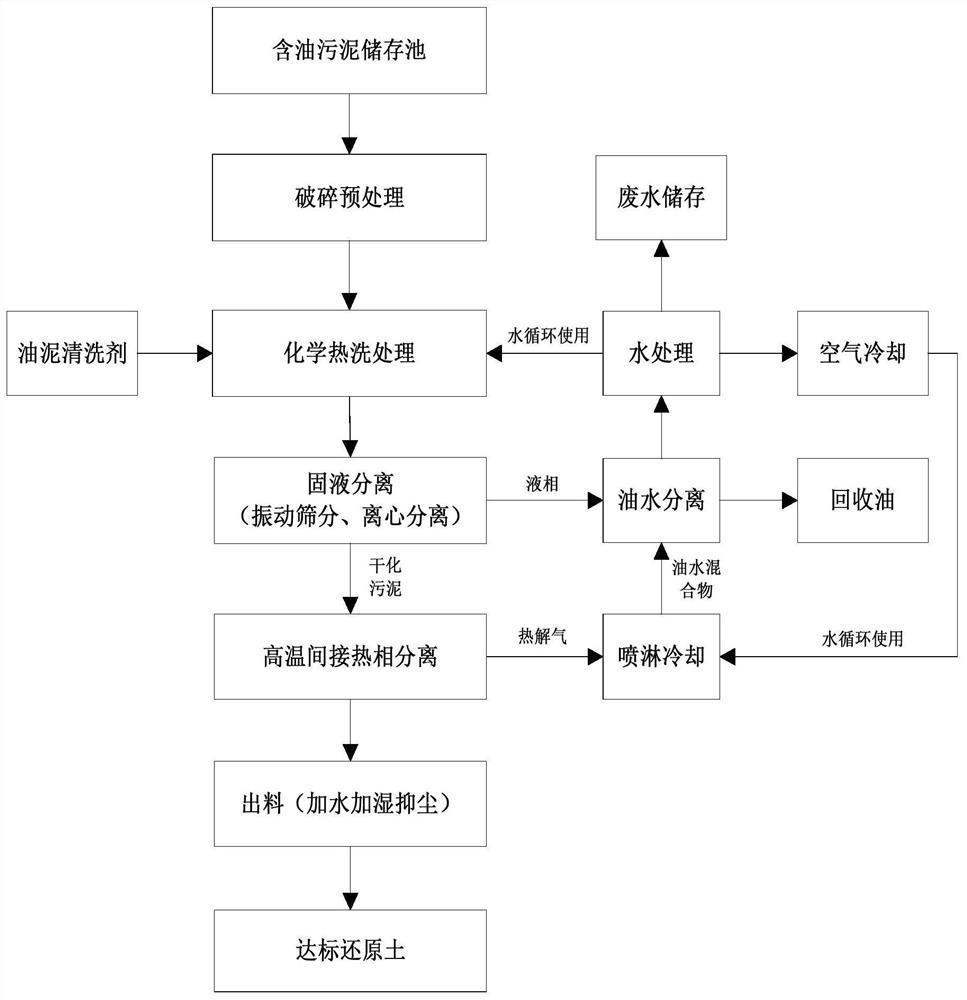

[0033] In an oilfield, crude oil pipeline leaks and pipeline ruptures caused crude oil leakage, which polluted a large area of surface soil. The oilfield concentrated and transported such oily sludge to the solid waste liquid treatment station for safe storage. The contaminated soil stock in the station reached 120,000 cubic meters. The annual increment is about 30,000 cubic meters. The method of the present invention is used to carry out combined treatment of chemical heat washing and rotary high-temperature indirect thermal phase separation on oily sludge. The treatment steps are as follows: figure 1 shown. mainly includes:

[0034] (1) Material crushing pretreatment

[0035] Some oily sludge is shipped in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com