Xanthene-based pigment, dye composition, coloring agent and coloring method for anodic aluminum oxide, and method for producing pigment

A dye composition, anodized aluminum technology, applied to diphenoxanthamine/xanthone/thioxanthone/selenoxanthone/telloxanthone dyes, organic dyes, triarylmethane dyes and other directions, which can solve problems such as hue and insufficient light fastness

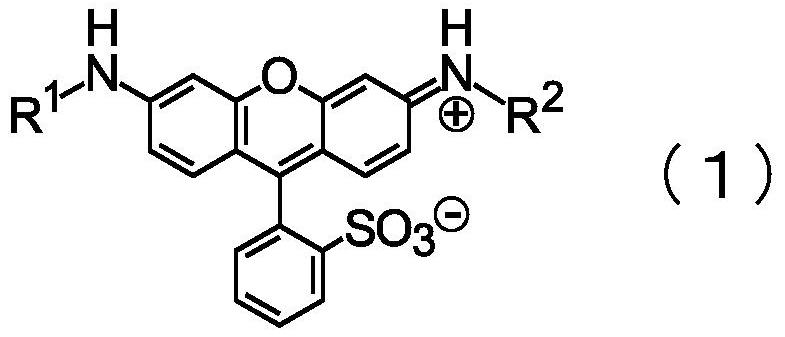

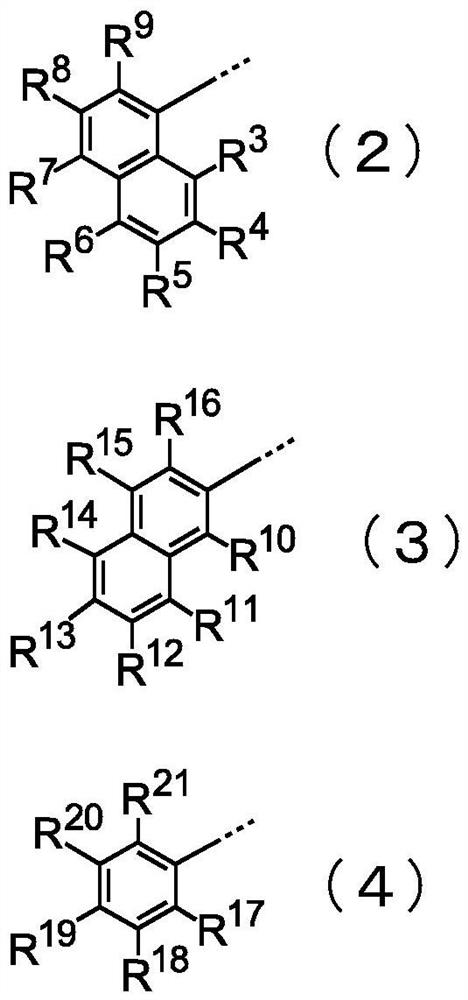

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0187]

[0188] Anodizing treatment was performed on an aluminum substrate in the following procedure to produce colored aluminum. In addition, in the process of anodizing and dyeing, processing time and dye compound density|concentration are set.

[0189] (Degreasing) In a container, prepare a mixture of 150 mL of a degreasing agent (Okuno Pharmaceutical Co., Ltd., Top ADD-100), 70 mL of 98% sulfuric acid, and 1,000 mL of water as a degreasing liquid, and cut the dyed The aluminum substrate was dipped, degreased at 60°C for 3 minutes, and washed with water after the treatment.

[0190] (Anodic oxidation) Use 98% sulfuric acid to prepare 180g / L electrolyte, connect the aluminum substrate to the electrode of the electrolysis device, immerse in the electrolyte tank, at a temperature of 19-21°C and a current density of 1.0A / dm 2 Anodization was performed under the conditions of the following energization time to obtain an anodic oxidation film with the following thickness. Wa...

Embodiment 2~ Embodiment 4

[0199] Except having used the dye (1-2), (1-3), or (1-4) instead of the dye (1-1), it produced the colored aluminum plate by the method similar to Example 1, and evaluated the hue. The results are summarized in Table 1.

[0200] [Reference example 1 to reference example 4]

[0201] Instead of the dye (1-1), the following dyes not belonging to the present invention are represented by the following formula (the maximum absorption wavelength (λmax) (nm) of the aqueous solution is also shown.):

[0202] (D-1) C.I.Acid Red 289 (λmax: 526nm),

[0203] (D-2) C.I.Acid Violet 102 (λmax: 533nm),

[0204] (D-3) C.I.Acid Violet 9 (λmax: 529nm),

[0205] (D-4) C.I.Acid Red 92 (λmax: 538nm)

[0206] , using the same production conditions as in Example 1 to produce colored aluminum, and the evaluation results of the hue are summarized in Table 1.

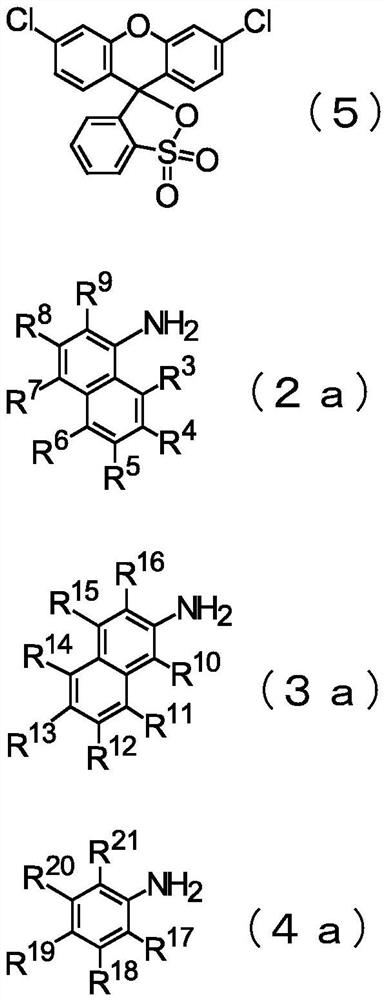

[0207] 【Chemical 32】

[0208]

[0209] 【Chemical 33】

[0210]

[0211] 【Chemical 34】

[0212]

[0213] 【Chemical 35】

[0214] ...

Embodiment 5

[0218]

[0219] About the colored aluminum plate colored using the pigment (1-3), the light resistance test was performed by the following method. For the use of xenon gas fading meter / ATLAS Ci 3000+Xenon Weather Ometer (manufactured by アトラス company), the irradiance: 300~400nm, 60W / m 2 , Temperature in the test tank: 38°C, humidity: 50%, blackboard (BP) temperature: 63°C, irradiated the colored aluminum plate for 50 hours, 100 hours and 200 hours, and carried out the hue and light irradiation with the color difference meter Color difference ΔE before and after * In addition, light fastness was judged by visual judgment of color fastness (JIS L 0804 "Gray scale for color change and fading") based on the number of gradation levels. In terms of levels, level 5 is the highest and level 1 is the lowest. The higher the level, the darker the color (color difference ΔE * Small), maintaining the hue before irradiation. In the evaluation method of the present invention, the determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com