Flue gas low-temperature heat recovery method and system of fuel gas process furnace

A low-temperature heat recovery and furnace flue gas technology, which is applied in the fields of energy saving and environmental protection, can solve problems such as large heat loss, high flue gas discharge temperature, low-temperature dew point corrosion, and ash accumulation structure, so as to save raw material gas, reduce combustion load, The effect of avoiding low temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments. The examples given are only used to explain the present invention and are not intended to limit the scope of the present invention.

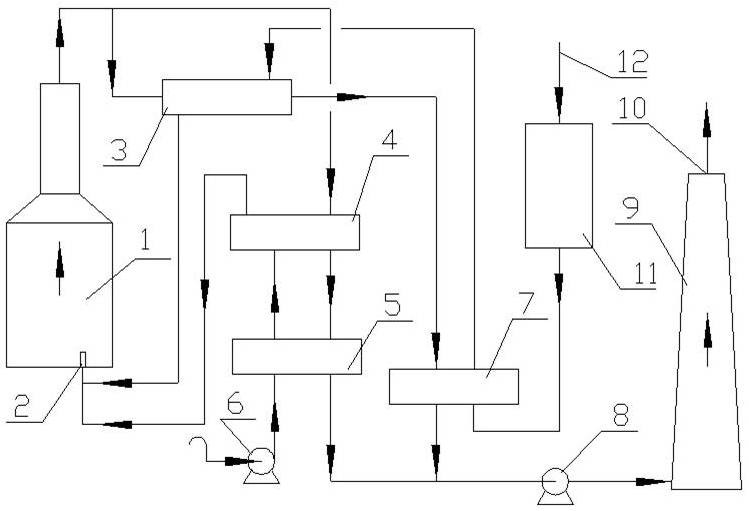

[0027] Such as figure 1 As shown, in order to achieve the above purpose, according to one aspect of the present invention, the present invention provides a low-temperature heat recovery system for flue gas from a gas-fired process furnace, including a fuel gas desulfurization preheating device, an air preheating device, a gas-fired process furnace 1, a combustion Device 2, negative pressure induced draft fan 8 and chimney 9; the outlet on the flue gas side of the fuel gas desulfurization preheating device and the outlet on the flue gas side of the air preheating device are connected in parallel with the negative pressure induced draft fan 8 inlet through a pipeline, The outlet of the negative...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap