Solid protective clothing for medical epidemic prevention or labor protection

A kind of protective clothing and solid-state technology, applied in the direction of protective clothing, clothing, clothing, etc., can solve the problems of few functional uses, lack of protective equipment, single raw materials, etc., achieve a wide range of use, improve the use range, and stable physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

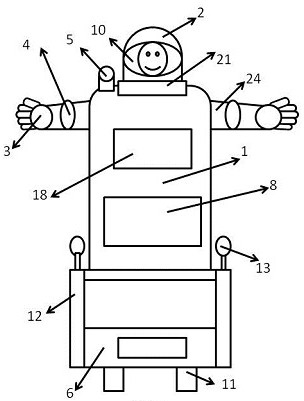

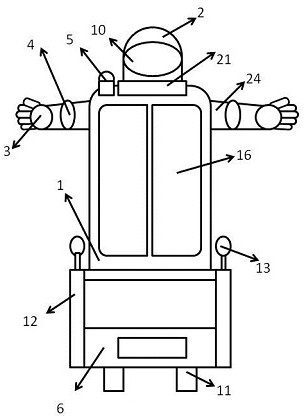

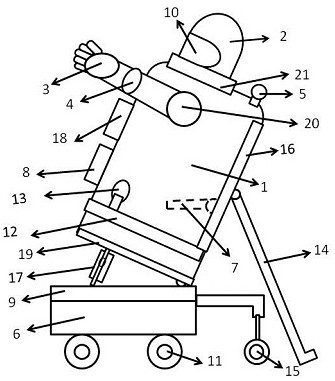

[0067] A solid protective suit, such as figure 1 As shown, the solid protective clothing includes a protective cabin 1, a protective helmet 2, a protective arm 3, a filter ventilation port 5, a driving device 6, a chassis 9, a support frame 12, a support rod 14, a hatch door 16, and a telescopic bar 17; The user performs operations outside the protective cabin 1 through the protective arm 3, and does not need to bear the weight of the protective clothing, which not only realizes the isolation and protection of the body, but also can easily move the operation; the production of solid protective clothing components is realized through the following steps:

[0068] Step 1. When the main material of the protective cabin 1 is metal, it can be cut and blanked and stamped; when plastic is used, it can be formed at one time by injection molding, extrusion, etc.; Different anti-seismic, thermal insulation or other protective materials;

[0069] Step 2, such as Figure 10 As shown, th...

Embodiment 2

[0087] A solid protective clothing, refer to Figure 9 , Figure 10 , Figure 11 , Figure 18 , the solid protective clothing includes a protective cabin 1, a chassis 9, a driving device 6, a protective helmet 2, a protective arm 3, a hatch 16, a filter vent 5, a controller 13, and an object box 8; the protective cabin 1 A protective helmet 2 is provided on the top; the protective cabin 1 is provided with a hatch 16, and the hatch 16 is preferentially set on both sides. The protective cabin 1 is also provided with a protective arm 3, and the protective arm 3 mainly allows the user's arm to extend out of the protective cabin. 1 outside; the protective cabin 1 is also provided with a filter vent 5, such as Figure 18 As shown, the user clamps or replaces the cloth 25 through the net buckle cover 27 and the net seat 26. The protective cabin 1 is also provided with a communication port, and the filter ventilation port 5 is preferentially used to communicate outside the protecti...

Embodiment 3

[0090] Referring to Example 1 or Example 2, another application method of the solid protective clothing of the present invention: for the protection of medical personnel, when the medical personnel use the protective equipment of the present invention, they first enter the protective cabin 1, and then perform external disinfection on the equipment , when nursing, operating or diagnosing patients, and making ward rounds, both doctors and patients can be protected; after use or when a new patient number is about to be replaced, they can directly enter the disinfection room for automatic disinfection again, which is better than traditional hand washing and disposable Clothes are safer and thoroughly disinfected, saving time and effectively reducing the rate of cross-infection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com