Engineered remediation equipment and remediation method for heavy metal arsenic and lead contaminated soil

A lead-contaminated soil and remediation method technology, applied in the field of heavy metal soil remediation, can solve the problems of not considering the cost economy of leaching, remediation technology, high requirements for site and personnel management, and increase of site circulation and utilization time. Avoid the risk of long-term monitoring, improve the efficiency of use, and improve the effect of repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

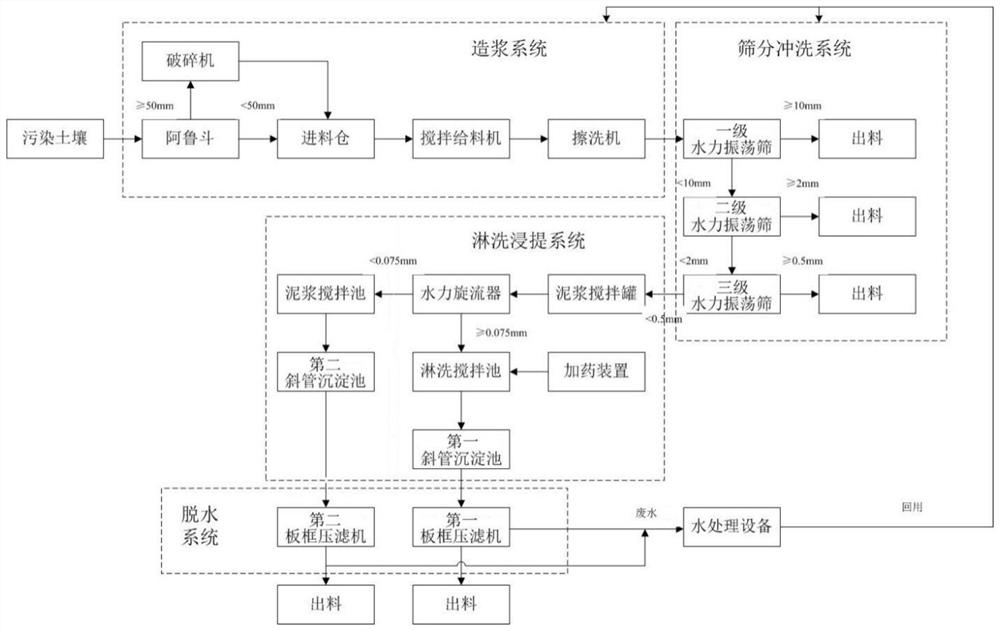

[0040] see figure 1 , the present embodiment provides a kind of engineered heavy metal arsenic, lead-contaminated soil restoration equipment, including a pulping system connected in sequence, a screening and flushing system, a leaching and extraction system and a dehydration system, wherein:

[0041]The pulping system includes a hopper connected in sequence, a feed bin, a stirring feeder and a scrubbing machine, and a crusher connected to the hopper and the feed bin via a branch line; The sieving particle size of Alu bucket is 50mm, the polluted soil with a particle size of less than 50mm is sent to the feeding bin, and the contaminated soil with a particle size greater than or equal to 50mm is sent to the crusher, and then sent to the feeding bin after being crushed. Silo; the mixing feeder and the scrubbing machine in this embodiment have a water-to-soil weight ratio of 3:1, and the slurry obtained by the stirring feeder and the scrubbing machine is sent to the Screening fl...

Embodiment 2

[0047] In this example, the arsenic and lead-contaminated soil left over from a smelter in Guangdong is used as the treatment target. The contaminated soil stratum is distributed as miscellaneous fill, silty clay and sandy clay, and the particle size is >0.5mm and ≤0.075mm. The weight percentage of soil particles They are 70% and 16% respectively. The proportion of arsenic and lead residue in soil is the highest, accounting for 40%-50%, followed by about 30% in water-soluble state. In the soil remediation process, the arsenic and lead-contaminated soil with a particle size > 0.5mm relies on physical sieving and washing to remove the loosely attached pollutants on the surface of the contaminated soil, and FeCl 3 As a leaching agent, leaching and leaching polluted soil with a particle size of 0.075-0.5mm can effectively remove arsenic and lead in the polluted soil. The specific method and related detection conditions are as follows:

[0048] (1) Pulping

[0049] The polluted so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com