Controllable gradient stent loaded with drugs, active factors and cells, 3D printing method of controllable gradient stent and special multi-nozzle 3D printer

A 3D printer and active factor technology, applied in the field of 3D printing of biological tissues and organs, can solve the problems of inability to achieve precise structure, no cells, poor controllability of the scaffold structure, etc., to achieve a simple and flexible printing process, and solve the problem of low adhesion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

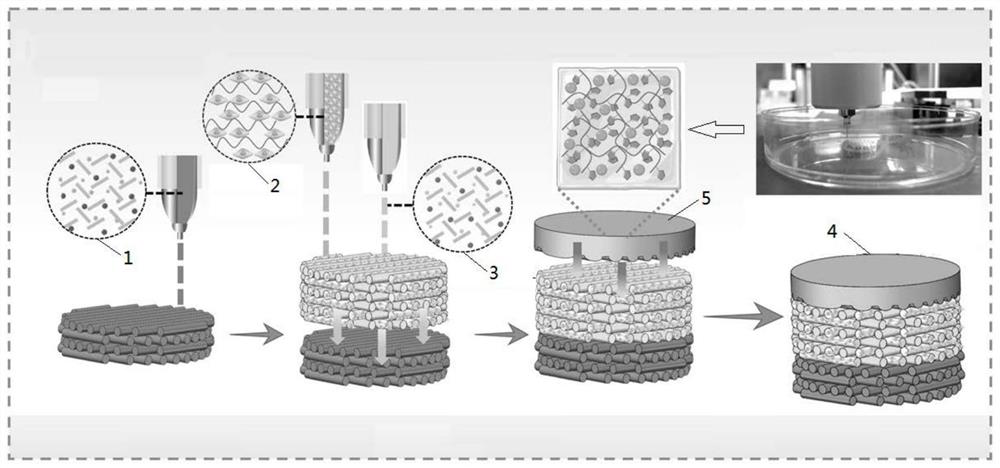

[0064] Embodiment 1 Osteochondral integrated scaffold

[0065] The osteochondral integrated scaffold of Example 1 includes a subchondral bone layer scaffold, a cartilage layer scaffold, and a hydrogel layer containing anti-inflammatory drugs in sequence from bottom to top, and the three-layer structure is firmly connected.

[0066] Among them, the subchondral bone layer scaffold is printed by printing ink-1 containing polycaprolactone and β-tricalcium phosphate, the molecular weight of the polycaprolactone used is 10000-100000, and the content of β-tricalcium phosphate is 5 %~40%;

[0067] The cartilage layer scaffold is printed alternately by two kinds of ink materials, namely printing ink 2 containing polycaprolactone and small molecular organic compound Kartogenin (KNG), containing double-bond hyaluronic acid, human mesenchymal stem cells hBMSCs, UV photoinitiator, water printing ink three 3; wherein, the molecular weight of the polycaprolactone used in printing ink two 2 ...

Embodiment 2

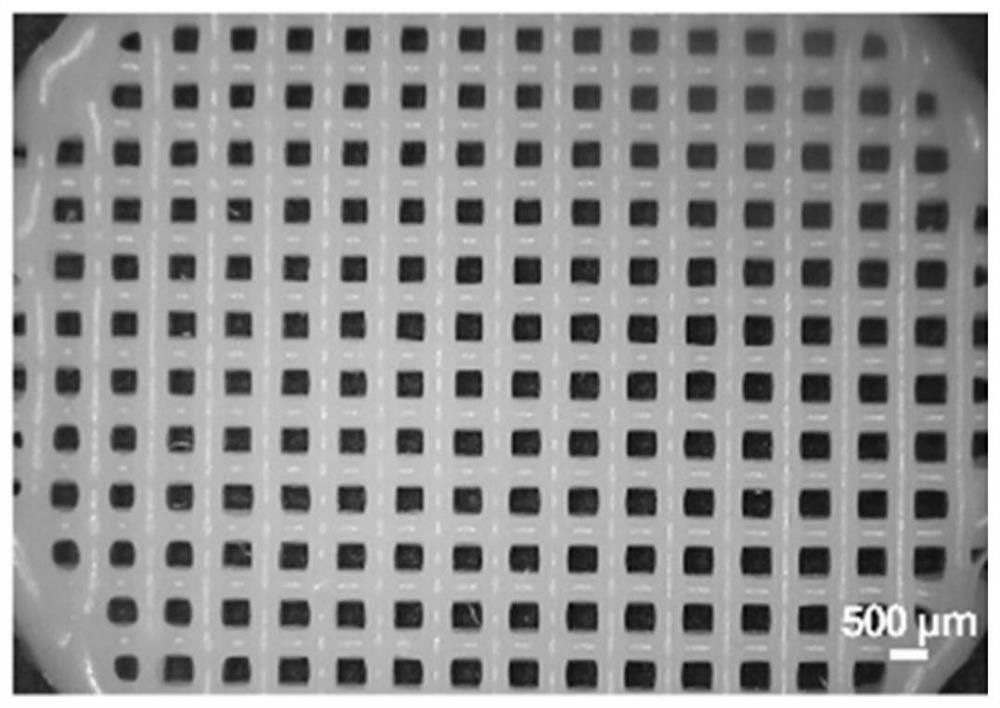

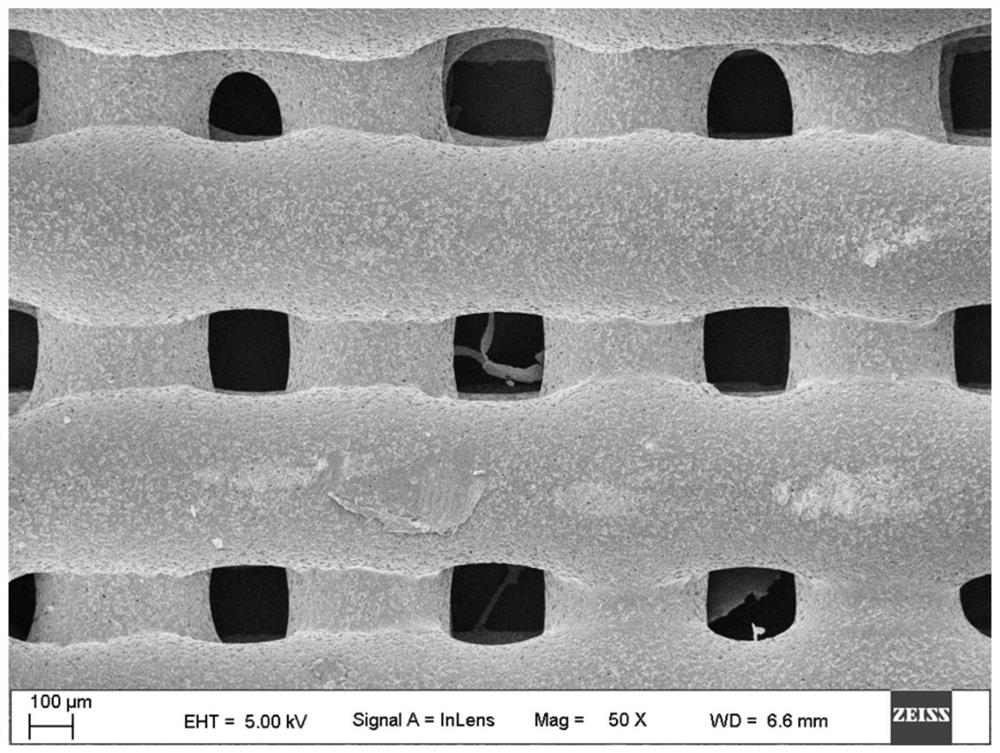

[0079] Embodiment 2 large size bone tissue support

[0080] Large-scale bone tissue scaffolds were alternately printed in one step by two materials in a multi-jet 3D bioprinter.

[0081] Wherein, the first material is printing ink 1 composed of polycaprolactone and β-tricalcium phosphate, the molecular weight of the polycaprolactone used is 10,000-100,000, and the content of β-tricalcium phosphate is 5%-40%;

[0082]The second material is a printing ink mixed with double bond grafted gelatin, double bond grafted sodium alginate, ultraviolet photoinitiator, water, human bone marrow mesenchymal stem cells and human umbilical vein endothelial cells; the double bond used The mass fraction of grafted gelatin is 5% to 20%, the mass fraction of double bond modified sodium alginate is 1% to 10%, the ultraviolet photoinitiator is 0.05% to 0.1%, and the rest is water; The densities of stromal stem cells and human umbilical vein endothelial cells were both controlled at 1×10 6 ~3×10 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com