Method for efficiently improving electron exchange capacity of biochar

A technology of exchange capacity and biochar, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of limited improvement of biochar's electron exchange capacity, differences that have not yet reached orders of magnitude, and insignificant improvement effect. The effect of reducing the consumption of activating agents, improving the application value and reducing the discharge of secondary pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028](1) Pinemaking 15h at 400 ° C for 15 hours to obtain raw materials to be activated, the supply electronics of raw material bio is 0.0217 mmol / g, the electronic ability is 0.1679 mmol / g, the BET specific surface area is 3.8m2 / g;

[0029](2) The raw material to be activated is immersed in water in water in a ratio of 1: 3, and then water is filtered, then the above process is repeated three times, and then bioaccha is placed in air and dried at 105 ° C for 12h. Then, the ball grinds the bio-carbon particle size at 25 to 75 microns;

[0030](3) A mixture of solid hydroxide after the biocarbon treatment after step (2) is not less than 85%, wherein the mass ratio of the activator and the biocarbon is (2 to 12): 1, after mixing Heat stirring at 80 ° C until the black colloidal mud was formed, and the mud was pinched with 1 h at 700 ° C, and the pyrolysis process continued to pass into nitrogen to ensure an oxygen atmosphere;

[0031](4) After the mud constant temperature in step (3) is ...

Embodiment 2

[0033]The activated bio-carbon is prepared by the same method as in Example 1, which is only that the raw material to be activated is obtained by pyrolysis of 5 h at 800 ° C for 5 h. The supply of raw material bio is 0.0197 mmol / g, The electronic ability is 0.1496mmol / g, the BET specific surface area is 11m2 / g.

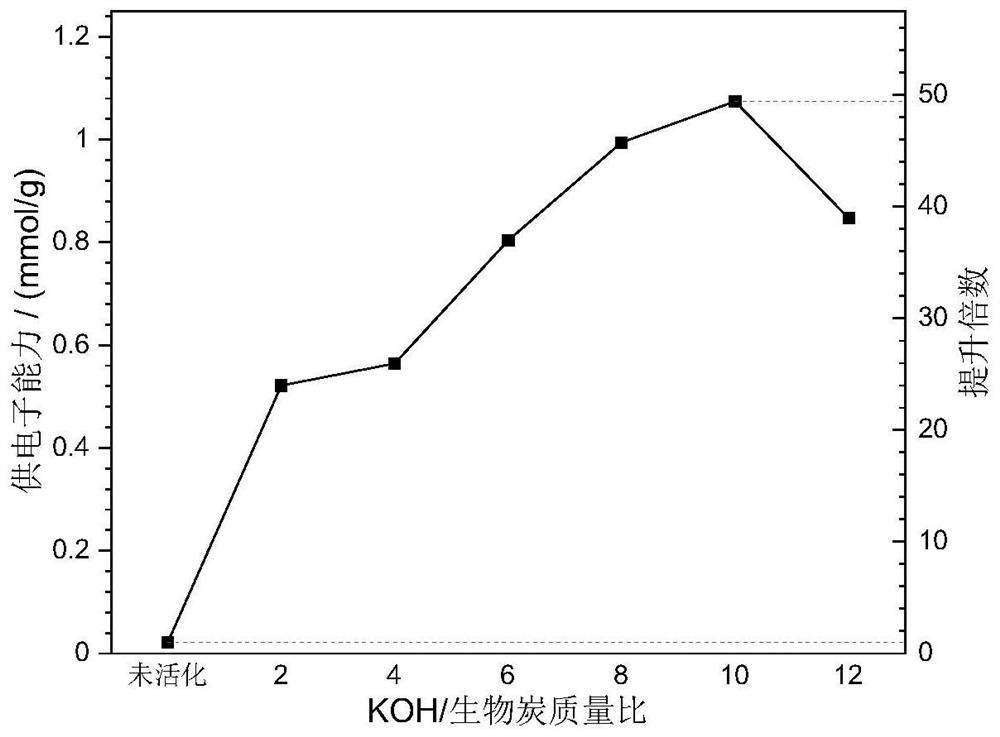

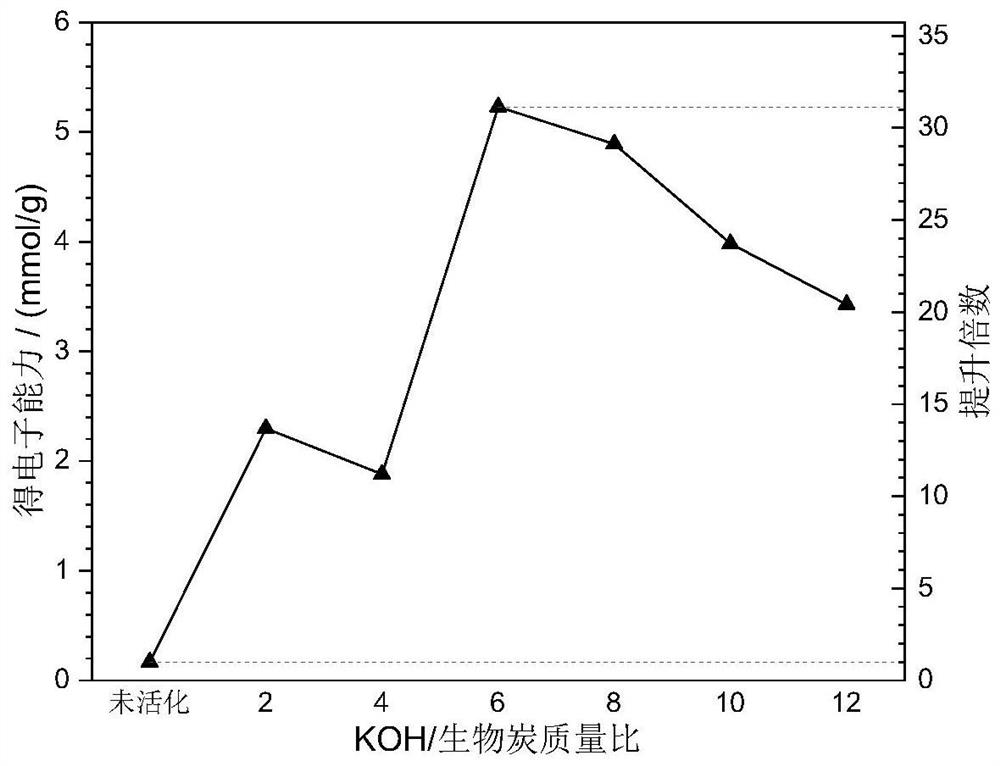

[0034]When the mass ratio of the biophero treated after the step (2) is 2, 4, 6, 8, 10, 12, respectively, the electronics of the activated biocompansion obtained by the present embodiment is 0.6645, respectively. 0.5267, 0.8429, 0.80937, 0.9472 and 0.8092 mmol / g, the electronic capabilities were 1.8354, 2.7869, 5.1752, 4.8356, 4.7358 and 3.892 mmol / g, Bet specific surface area is 1065, 1976, 2681, 3183, 2985, and 3041m, respectively, respectively, respectively.2 / g.

Embodiment 3

[0036]The activated biocarbon was prepared by the same method as in Example 1, which is only that the raw material to be activated is obtained by pyrolysis of 2 h at 500 ° C trimming branches at 500 ° C, and the electronics of raw material bio is 0.0247 mmol. / g, the electronic ability is 0.1827mmol / g, the BET specific surface area is 2.4m2 / g.

[0037]When the mass ratio of the biophero treated after the step (2) is 2, 4, 6, 8, 10, 12, respectively, the electronics of the activated biopco obtained by the present embodiment is 0.5023, respectively. 0.5513, 10.8946, 1.0090, 1.1823 and 0.7519 mmol / g, the electronic capacity is 2.3324, 3.9975, 5.9133, 4.2917, 4.9980 and 3.6301 mmol / g, Bet specific surface area is 1633, 2224, 2598, 3564, 3035, and 2836m, respectively.2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com