Control method for reducing content of 3-chloropropanol ester in beef tallow

A control method and technology of chloropropanol esters, which are applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of human health hazards and high content of 3-chloropropanol esters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

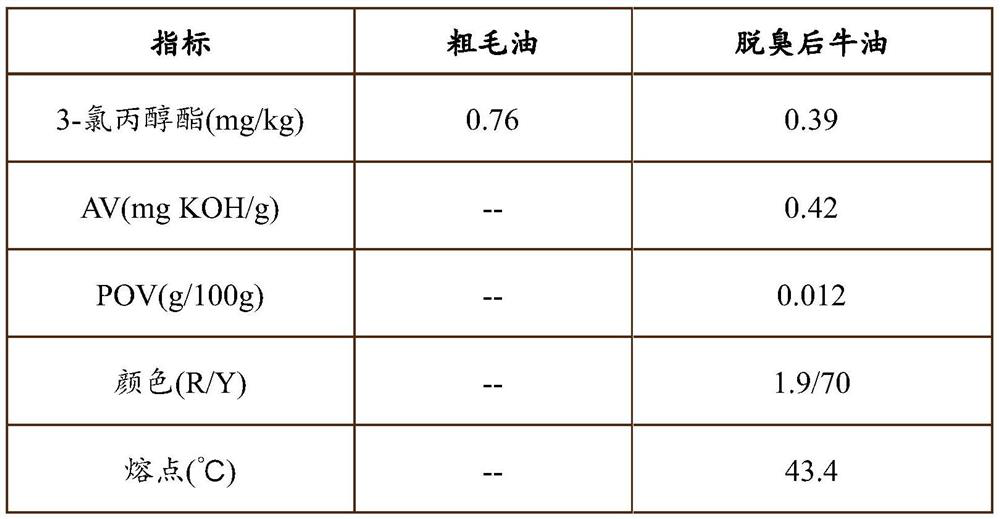

Examples

Embodiment 1

[0075] The present embodiment provides a control method for reducing the content of 3-chloropropanol in tallow, comprising the following steps:

[0076] Melting, washing and grinding the minced raw fat, and preheating the raw fat at 75°C, and then transporting the raw fat to the smelting kettle to heat and melt the raw fat at 125°C for 2 hours, and during the melting process, through a weak The water vapor generated during the raw fat smelting process is pumped away under the vacuum condition; the smelted fat is transported to the centrifuge for liquid slag separation, and then transported to the anti-stratification tank for precipitation to obtain smelted butter;

[0077] Degumming, transport the smelted butter to the degumming tank, first control the temperature of the smelted butter at 65°C, then add 65°C dechlorinated soft water and solid citric acid, and stir at 40r / min for 20min Remove the colloid, after standing for 2 hours, centrifuge the colloid to obtain the degummed...

Embodiment 2

[0086] The present embodiment provides a control method for reducing the content of 3-chloropropanol in tallow, comprising the following steps:

[0087] Melting, washing and grinding the minced raw fat, and preheating the raw fat at 75°C, and then transporting the raw fat to the smelting kettle to heat and melt the raw fat at 118°C for 3 hours, and during the melting process, through a weak The water vapor generated during the raw fat smelting process is pumped away under the vacuum condition; the smelted fat is transported to the centrifuge for liquid slag separation, and then transported to the anti-stratification tank for precipitation to obtain smelted butter;

[0088]Degumming, transport the smelted butter to the degumming tank, first control the temperature of the smelted butter at 65°C, then add 65°C dechlorinated demineralized water and solid citric acid, and stir at 40r / min for 20min Remove the colloid, after standing for 2 hours, centrifuge the colloid to obtain the ...

Embodiment 3

[0098] The present embodiment provides a control method for reducing the content of 3-chloropropanol in tallow, comprising the following steps:

[0099] Smelting, cleaning the minced raw fat, preheating the raw fat at 75°C, and then transporting the raw fat to a melting kettle for heating and melting at 120°C for 2.7 hours, and during the melting process, through the The weak vacuum condition removes the water vapor generated during the raw fat smelting process; the smelted fat is transported to the centrifuge for separation of liquid slag, and then transported to the anti-stratification tank for precipitation to obtain smelted butter;

[0100] Degumming, transport the smelted butter to the degumming tank, first control the temperature of the smelted butter at 65°C, then add 65°C dechlorinated soft water and solid citric acid, and stir at 40r / min for 20min Remove the colloid, after standing for 2 hours, centrifuge the colloid to obtain the tallow after degumming; wherein, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com