A kind of preparation method of flame retardant smoke suppression fatliquoring agent comprising metal organic framework uio-66 composite material

A metal-organic framework and composite material technology, which is applied in the field of preparation of flame-retardant and smoke-suppressing fatliquoring agents, can solve problems such as difficulty in dispersing hydrotalcite, and achieve the effects of improving dispersibility, good biocompatibility and shortening reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention is a method for preparing a flame-retardant, smoke-suppressing and fatliquoring agent comprising a metal-organic framework UiO-66 composite material, comprising the following steps:

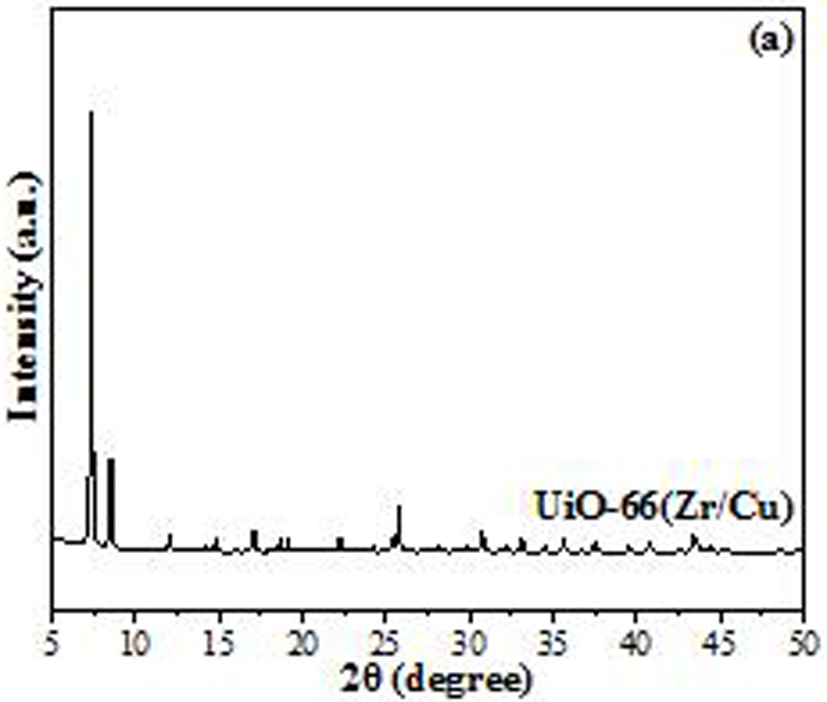

[0025] Step 1: ultrasonically dissolve 0.63 parts by mass of zirconium chloride and 0.05-0.46 parts by mass of copper chloride in 25 parts by mass of N,N-dimethylformamide; ultrasonically dissolve 0.45 parts by mass of terephthalic acid and 5 parts by mass of acetic acid in 25 parts by mass of N,N-dimethylformamide; the two solutions were mixed evenly, kept at 120°C for 24h, cooled to room temperature naturally, alternately washed with N,N-dimethylformamide and methanol, and vacuum-dried at 60°C, namely Copper-doped modified zirconium-based metal-organic framework UiO-66 (Zr / Cu);

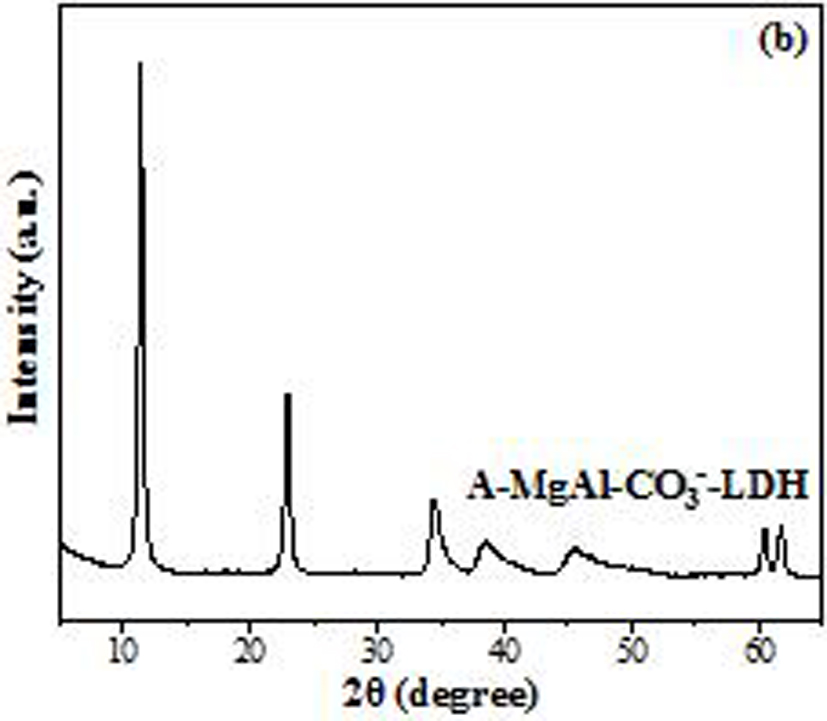

[0026] Step 2: Dissolve 10.60 parts by mass of sodium carbonate in 100 mL of deionized water, transfer to a three-necked flask, stir at 60°C for 30 minutes; heat up to 80°C, add dropwise a water mi...

Embodiment 1

[0032]Step 1: 0.63 parts by mass of zirconium chloride and 0.05 parts by mass of copper chloride are ultrasonically dissolved in 25 parts by mass of N, N-dimethylformamide; 0.45 parts by mass of terephthalic acid and 5 parts by mass of acetic acid are ultrasonically dissolved in 25 parts by mass N, N-dimethylformamide; mix the two solutions evenly, keep warm at 120°C for 24 hours, cool to room temperature naturally, wash alternately with N,N-dimethylformamide and methanol, and dry under vacuum at 60°C to obtain copper Doping modified zirconium-based metal-organic framework materials (UiO-66(Zr / Cu));

[0033] Step 2: Dissolve 10.60 parts by mass of sodium carbonate in 100 mL of deionized water, transfer to a three-necked flask, stir at 60°C for 30 minutes; heat up to 80°C, add dropwise a water mixture of 2.57 parts by mass of magnesium nitrate and 1.88 parts by mass of aluminum nitrate to control the reaction The pH of the process, reacted for 30min, aged for 8h, washed alterna...

Embodiment 2

[0036] Step 1: 0.63 parts by mass of zirconium chloride and 0.12 parts by mass of copper chloride are ultrasonically dissolved in 25 parts by mass of N, N-dimethylformamide; 0.45 parts by mass of terephthalic acid and 5 parts by mass of acetic acid are ultrasonically dissolved in 25 parts by mass N, N-dimethylformamide; mix the two solutions evenly, keep warm at 120°C for 24 hours, cool to room temperature naturally, wash alternately with N,N-dimethylformamide and methanol, and dry under vacuum at 60°C to obtain copper Doping modified zirconium-based metal-organic framework materials (UiO-66(Zr / Cu));

[0037] Step 2: Dissolve 10.60 parts by mass of sodium carbonate in 100 mL of deionized water, transfer to a three-necked flask, stir at 60°C for 30 minutes; heat up to 80°C, add dropwise a water mixture of 2.57 parts by mass of magnesium nitrate and 1.88 parts by mass of aluminum nitrate to control the reaction The pH of the process, reacted for 30min, aged for 8h, washed altern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com