Converter vanadium extraction coolant and application thereof

A coolant and converter technology, which is applied in the process of vanadium extraction from converter and the field of vanadium extraction coolant from converter, can solve the problems of less improvement in coolant technology, easy to be blown away by air flow, low relative density, etc., and achieve good bonding performance, Stable cooling effect and less splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0032] S1: Mix 20 parts of air-dried iron ore and 100 parts of iron oxide scale, then add 8 parts of quicklime powder and 4 parts of lightly burned dolomite powder and stir and mix; S2: Use a ball press to form balls and dry them in a drying furnace at 100 °C Dry to obtain the iron ore-iron oxide complex.

preparation example 2

[0034] S1: Mix 10 parts of air-dried iron ore and 100 parts of iron oxide scale, then add 10 parts of quicklime powder and 2 parts of lightly burned dolomite powder and stir and mix; S2: Use a ball press to form balls and dry them in a drying furnace at 100°C Dry to obtain the iron ore-iron oxide complex.

preparation example 3

[0036] S1: Mix 10 parts of air-dried iron ore and 100 parts of iron oxide scale, then add 10 parts of quicklime powder and 1 part of lightly burned dolomite powder and stir and mix; S2: Use a ball press to form balls and dry them in a drying furnace at 100°C Dry to obtain the iron ore-iron oxide complex.

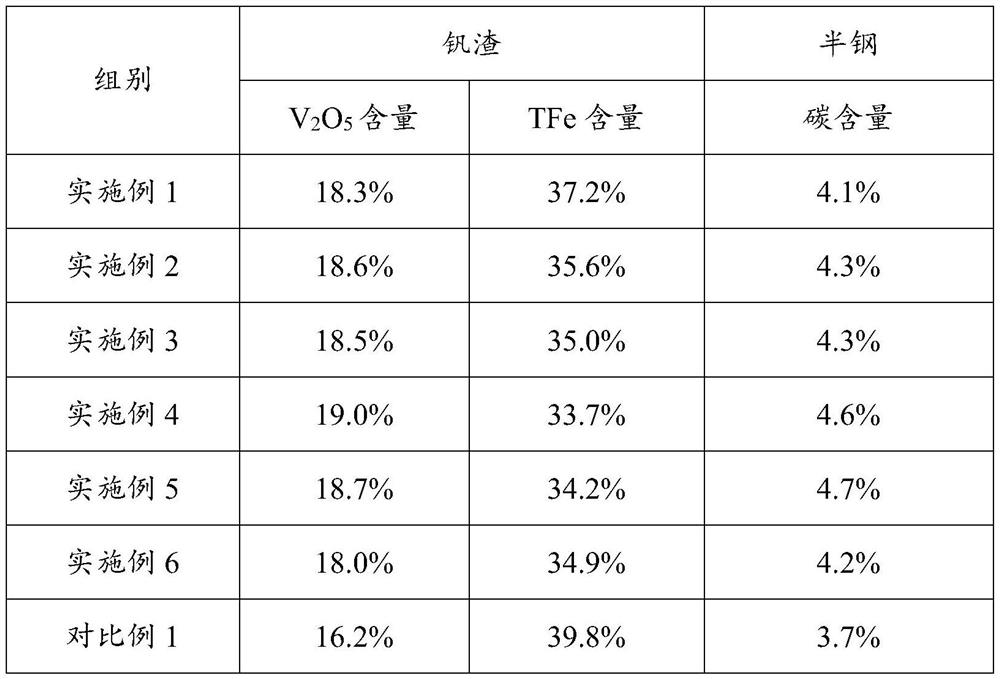

[0037] Example of Vanadium Extraction Process in Converter

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com