High-pressure diving suit detection device and method

A technology for detection devices and diving suits, applied in the direction of detecting the presence of fluid at the leak point, testing the strength of materials by applying stable tension/pressure, and measuring liquid tightness by using liquid/vacuum, which can solve the problem of data and theory Value deviation and other issues, to achieve the effect of reducing the heating process, good adhesion, good flexibility and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

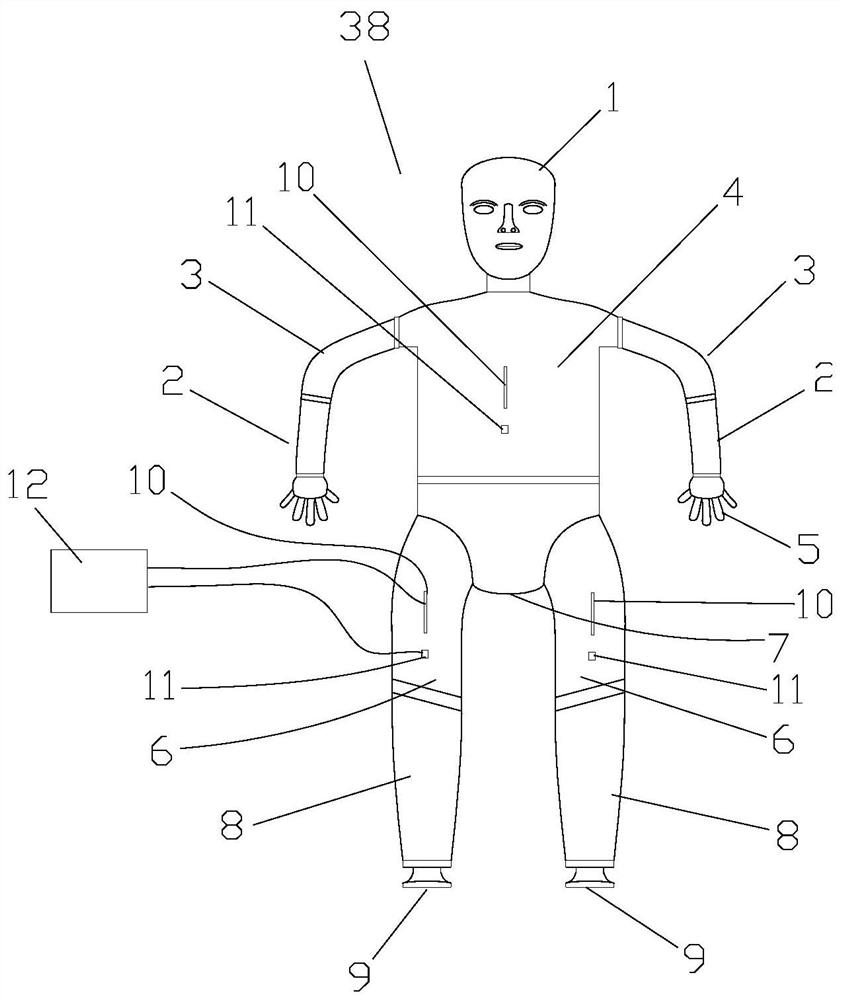

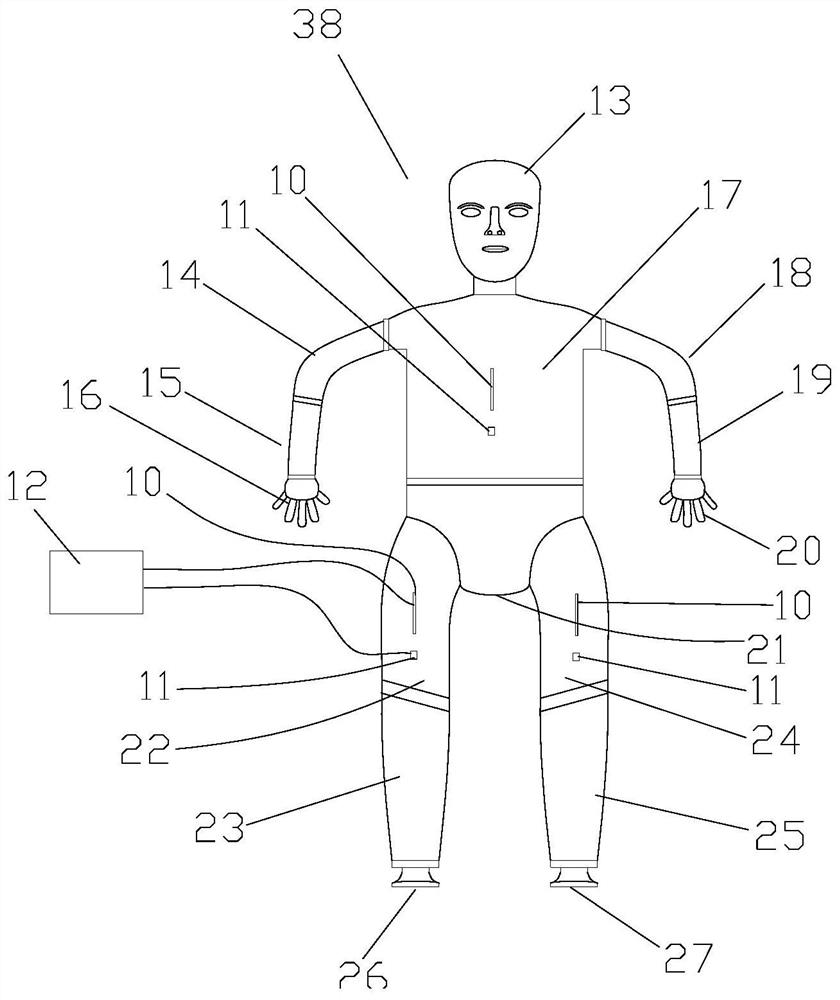

[0053] Such as figure 1 As shown, a hyperbaric diving suit detection device includes a thermal manikin 38, and the thermal manikin 38 includes the following 9 parts units: head unit 1; torso unit 4; hip unit 7; forearm unit 2; upper arm unit 3; hand unit 5; thigh unit 6; calf unit 8; foot unit 9,

[0054] Electric heating devices 10 for heating the thermal manikin 38 are respectively arranged on multiple parts of the thermal manikin 38;

[0055] Such as Figure 5 As shown, it also includes a temperature monitoring system 34 for monitoring the real-time temperature of the thermal manikin 38. The temperature monitoring system 34 includes a plurality of temperature sensors 11, and the plurality of temperature sensors 11 are respectively arranged on the thermal manikin 38. on multiple parts of the

[0056] The temperature control system 12 for controlling the heating input power of the electric heating device, the temperature control system 12 includes a temperature control cir...

Embodiment 2

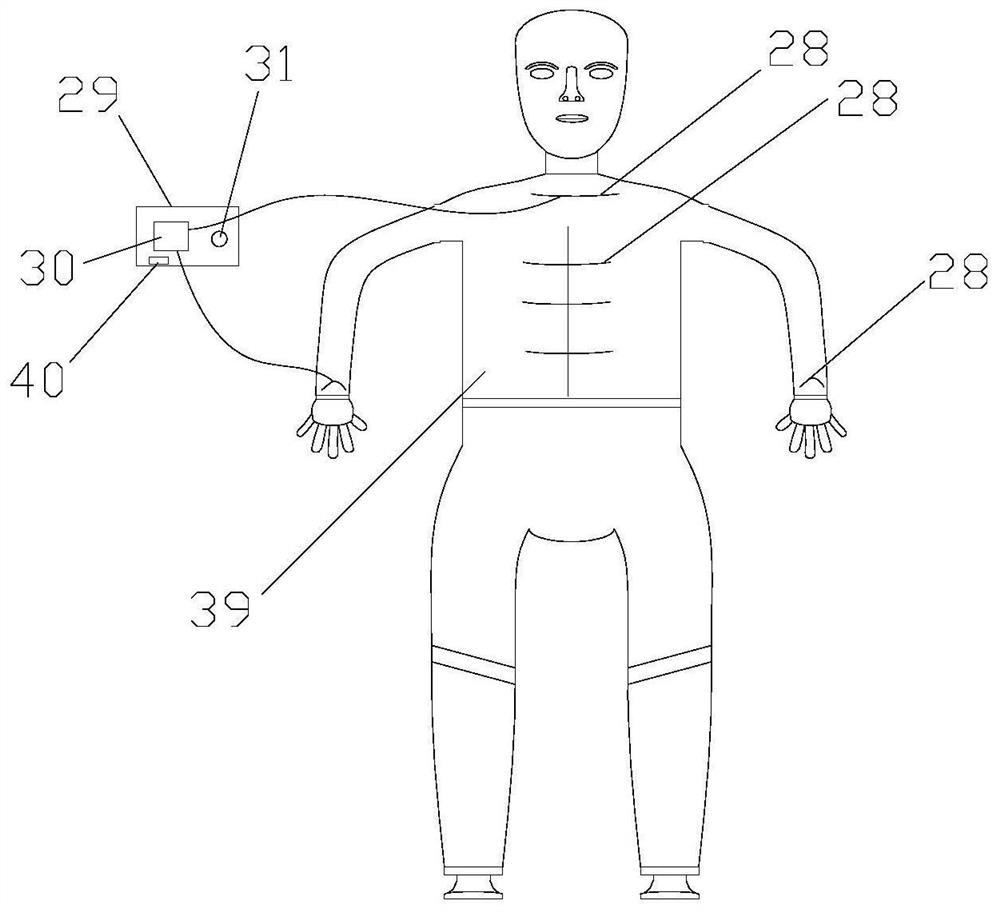

[0071] The implementation scheme of the pressure-resistant structure of the high-pressure diving suit detection device includes: 1. cavity structure, 2. solid structure;

[0072] Among them, the cavity structure is made by the following method:

[0073] S1. Use the machining center to process the human body imitation copper shell or open the mold, and process and install the heating plate and temperature sensor;

[0074] S2, installing and fixing the heating plate and the temperature sensor 11 on the copper shell 32;

[0075] S3. Add a Teflon jacket to the outgoing lines at both ends of the 38-part unit of the thermal manikin;

[0076] S4. Connect the outgoing line of one end of the 38-part unit of the thermal manikin to a waterproof and pressure-resistant connector;

[0077] S5, testing the heating temperature measurement module;

[0078] S6, welding the copper shell 32;

[0079] S7. Fill the inner cavity of the 38 units of the thermal manikin and insert the Teflon tube i...

Embodiment 3

[0137] A heating scheme for a high-pressure diving suit detection device:

[0138] Trunk part: Due to the large surface area of the trunk part, it is necessary to distribute the heating at each point evenly, otherwise there will be a gradient temperature difference in the trunk. The trunk is divided into 6 areas for separate heating control. According to the single area of the trunk, the heating power is 114w. The heating density is 1w / cm2. The area of the silicone heating plate is required to be greater than 114cm2. According to the structure of the torso, the power of 6 irregular heating sheets of 150x80x1.5mm is 120w, and the total power available is 720w. It is mounted on the inner surface of the copper housing 32 as follows.

[0139] Buttocks: Due to the relatively large surface area of the buttocks, it is necessary to distribute the heating at each point evenly, otherwise there will be a gradient temperature difference in the torso. The buttocks are divided int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com